Posted by Shaun Belcher on 27/11/2019 10:36:41:

Posted by mark smith 20 on 27/11/2019 09:37:14:

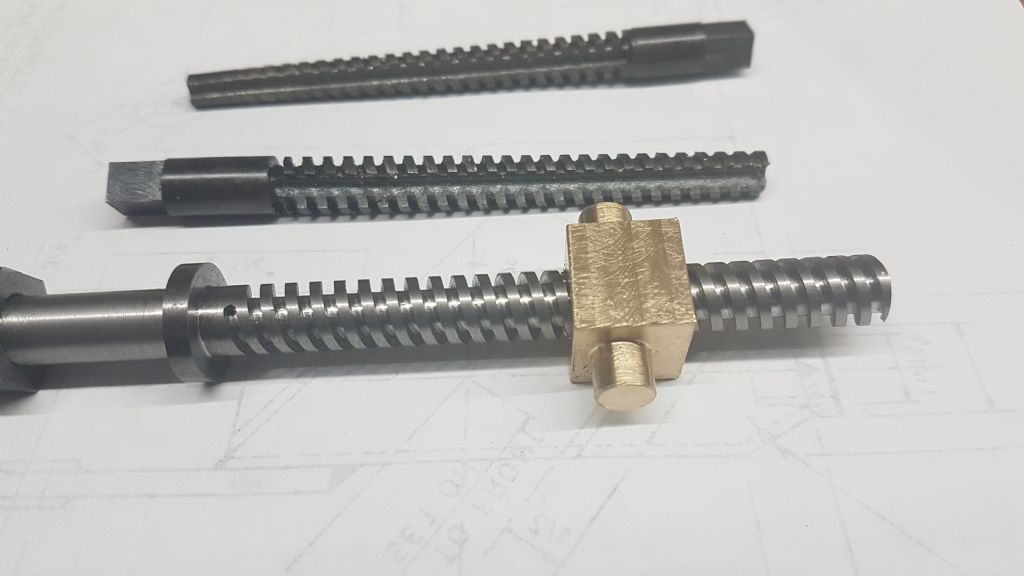

Shaun , a slightly larger diameter screw would still work the same in regard to the dials if the pitch TPI is the same .(as long as everything else is machined to fit (the nut, dials ,handles etc…)

Edited By mark smith 20 on 27/11/2019 09:37:59

Thanks, thats all I need to know.

I would hate to find the dials were not accurate if i used this feedscrew.

Im actually considering making my own resettable dials anyway, but would need to CNC engrave the markings on the outside accurate enough

Dials will still be accurate. The imperial dials you have have are graduated in 100 graduations. This becomes then 1/100th of the 2mm pitch of your feedscrew or .02mm. Diameter of screw makes no difference.

Model engineers were engraving dials long long long before CNC was invented. You engrave the lines with a sharp lathe tool mounted sideways in the tool post that is racked back and forth by the carriage handwheel, using a carriage stop to control length of the line.

Position of the lines is controlled by a pointer or similar engaging with the correctly set up change gears on the headstock quadrant. To get 100 graduations, you use a 50 tooth gear meshing with a 25 on the spindle, or some similar 2:1 reduction combination of gears such as 20 on the spindle meshing with a 40 which has the 50 tooth gear on the same stud.

You then stamp the numbers on using number stamps and a hammer. A simple jig to hold the dial and punch in the right positions helps make a tidy job.

Many of the old ME books by G H Thomas, LH Sparey, Ian Bradley etc cover the technique. Thomas in the most detail. His "Model Engineers Workshop Manual" includes the drwaings and instructions to make resettable dials for a Myford.

Edited By Hopper on 28/11/2019 01:24:27

Baldric.