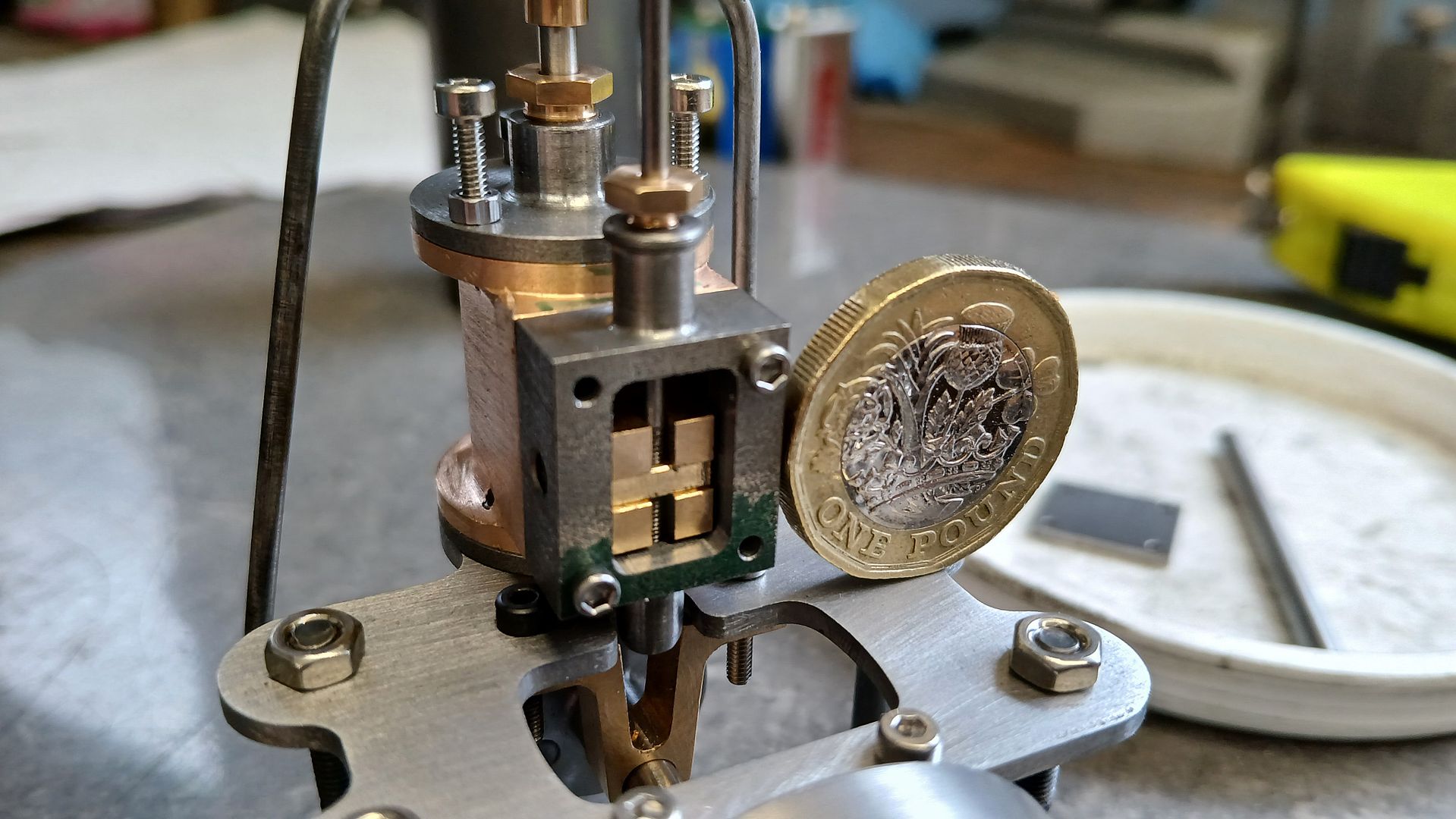

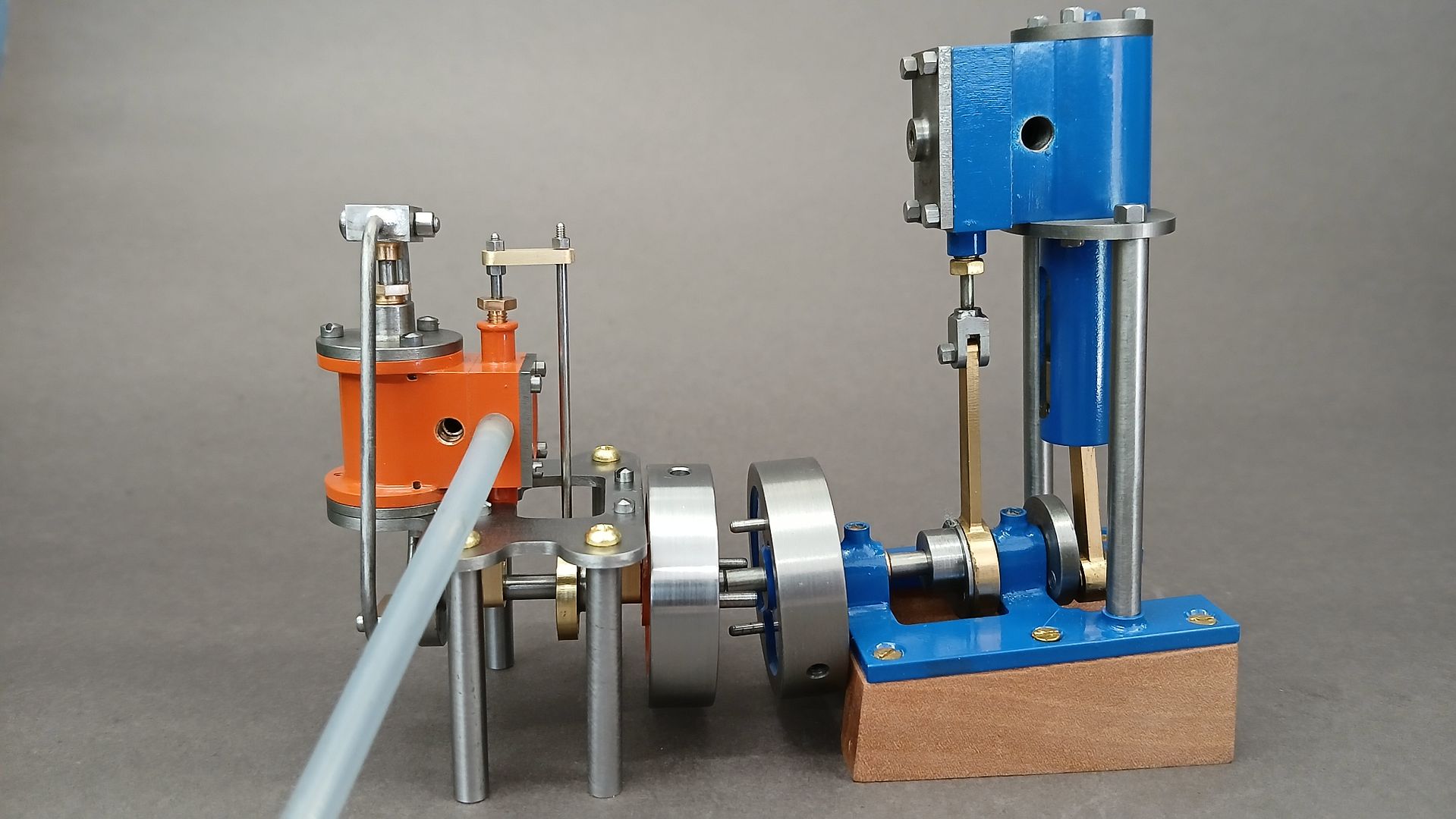

Sanjay (Redhouseluv) posted some images of a small unknown engine in this thread on MEM Forum at the beginning of April. It will now always be known as “Sanjay’s Banjo Engine”.

https://www.modelenginemaker.com/index.php/topic,12258.0.html

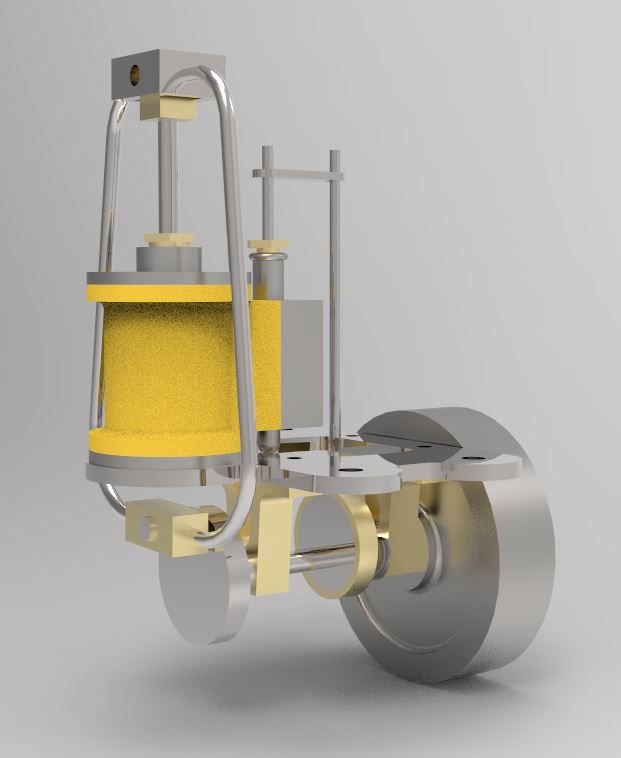

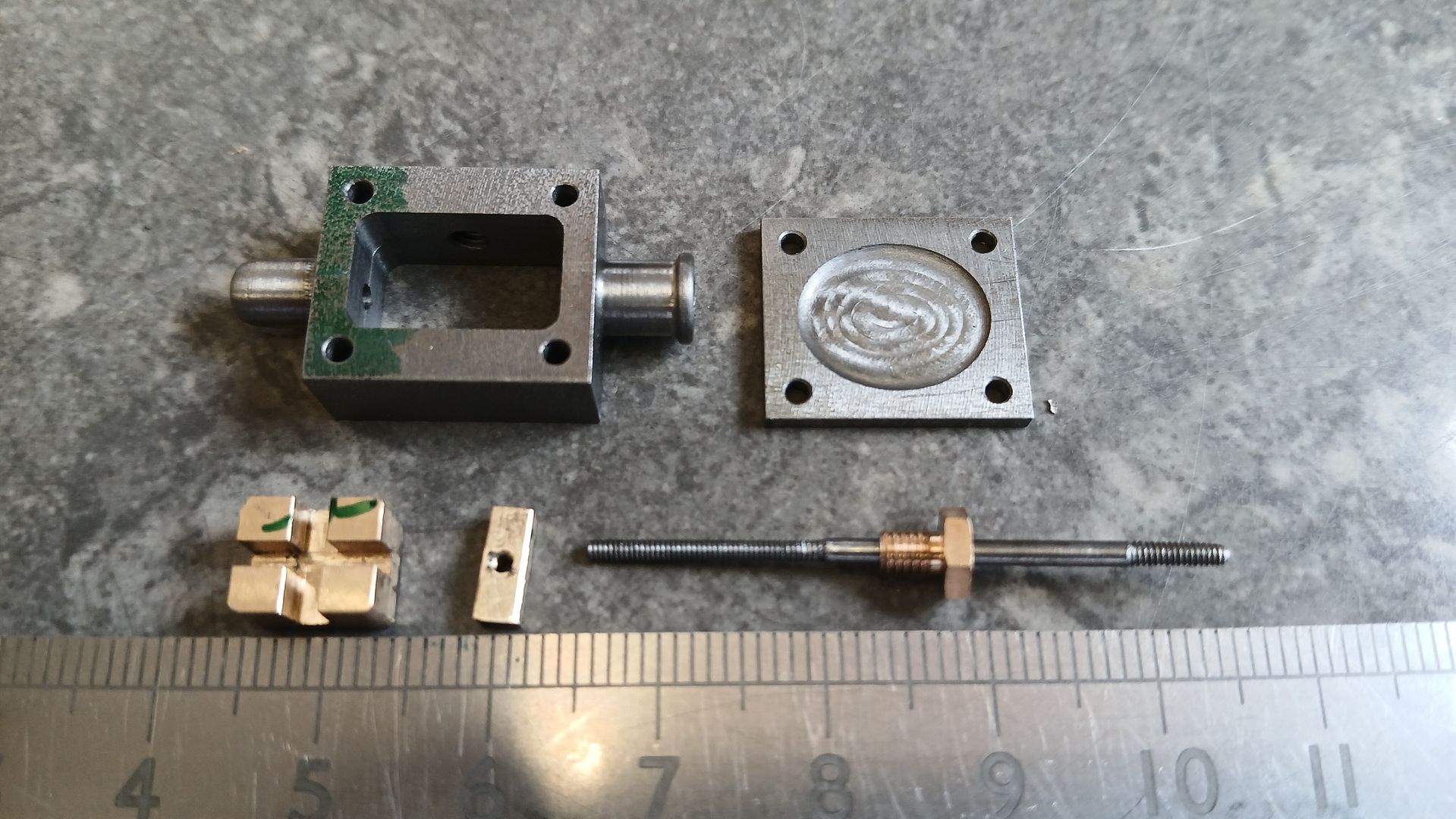

I was quite taken with its looks and although I had made a pump with the banjo type arrangement in the past I had not done an engine with the crankshaft in this form which is not unlike his recent Trapizoidal engine. A couple of evenings on and off with Alibre making use of “trace” to pick sizes off of a screen shot of the laid out parts and I had something that looked the part and while designing it gave some thought as to how I would go about making it. As usual I did the design in metric and it has a bore and stroke of 13mm x 13mm.

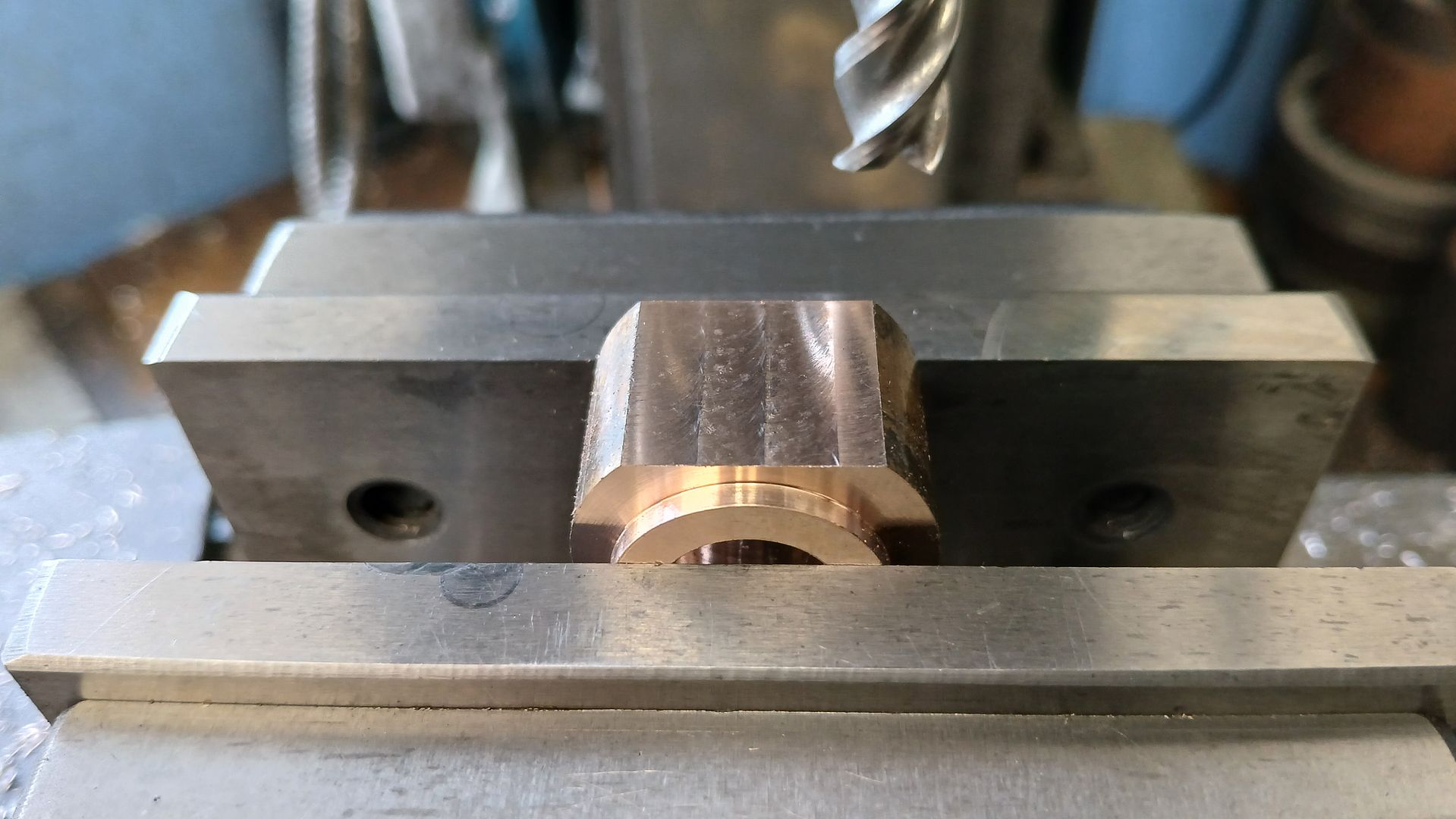

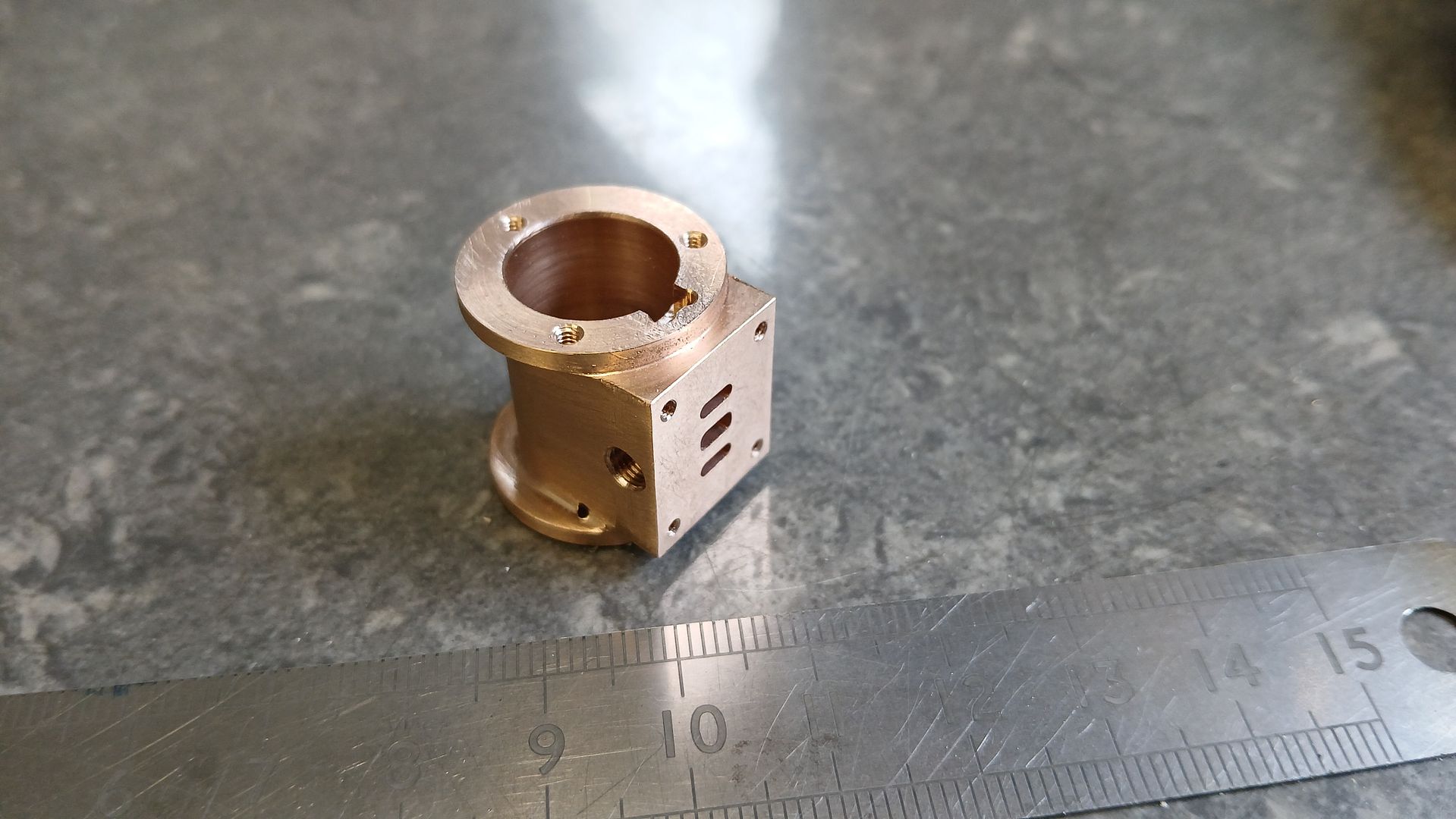

It was a toss up between using iron or bronze for the cylinder but in the end a piece of bronze bar won the day. After facing the end I turned a 2mm length to the diameter of the top flange before drilling and finally boring to the final 13mm diameter. it was then reversed in the chuck and the bore clocked true before facing to final length and forming a similar flange diameter as the other end.

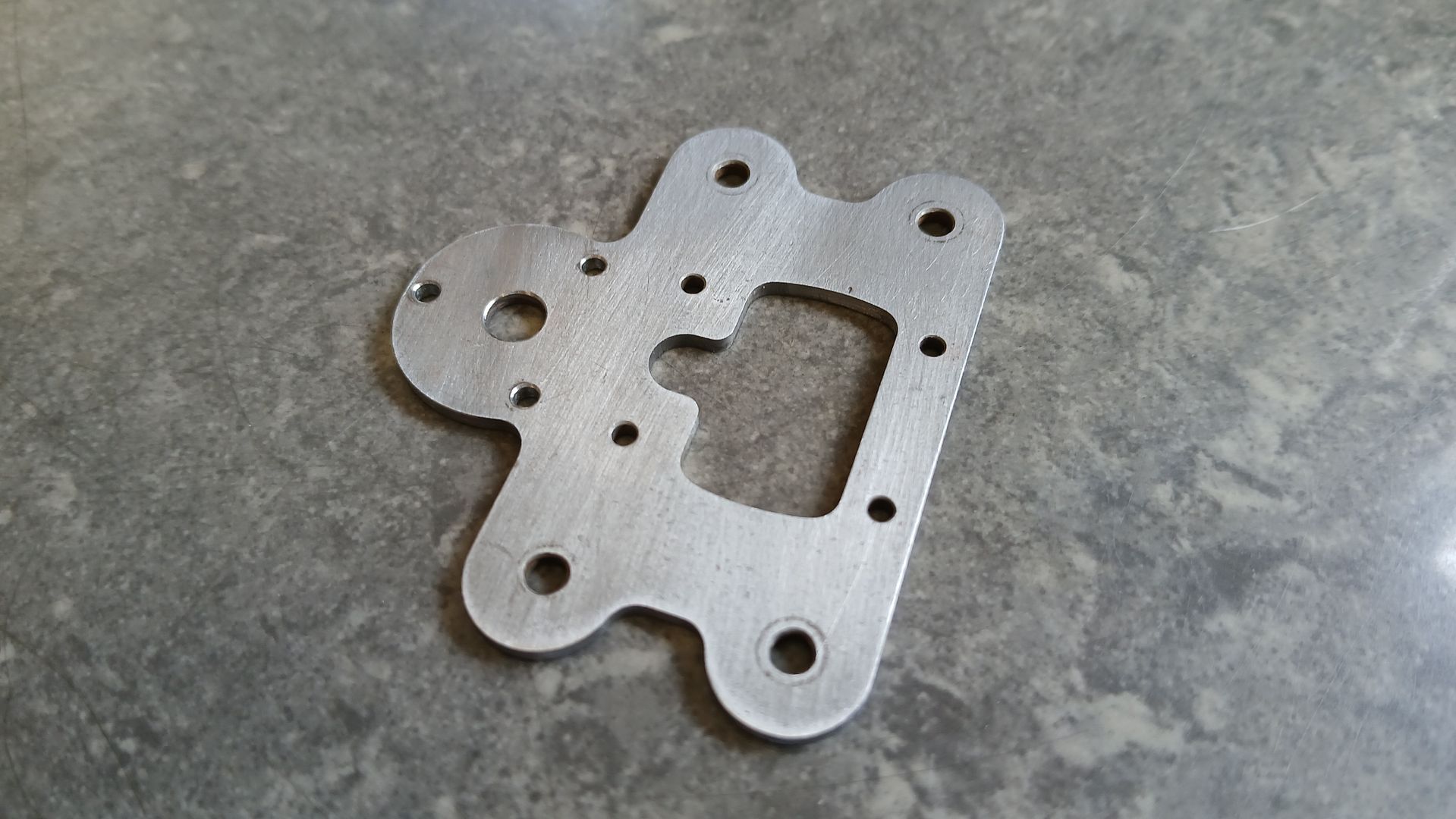

I roughly squared up 3 faces of the mid section so it was easier to hold and then took the port face to it’s final height.

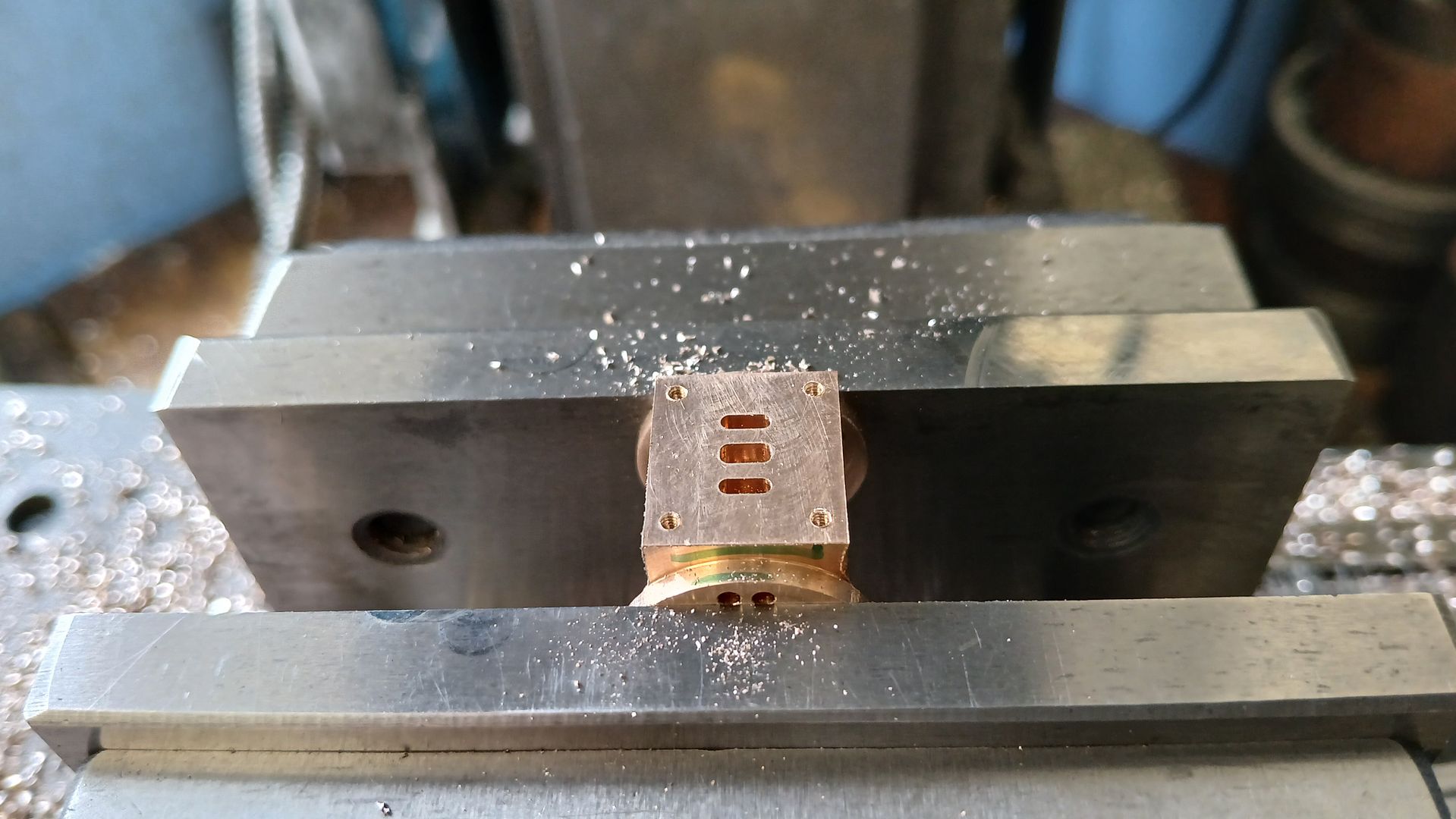

The end cover screw holes were drilled and tapped M2 and two 1.5mm holes drilled down to where the inlet ports would be, doing the holes first meant that the drill would not break out into the side of the port and risk snatching or worse. Repeat for the other end as well as milling a notch so the end cover spigots do not restrict steam/air flow.

Over to the CNC which made a relaxing job of cutting the three ports slots. The outer ones are 1.5 x 4mm and the middle is 2 x 4mm. Back on the manual mill and the valve chest stud holes were drilled and tapped M1.6

A quick hole in the side to link up to the central exhaust port tapped m4 x 0.5 was the final drilling operation. I then supported the cylinder on a 12mm ground bar resting across the tops of the vice jaws and using a 10mm R1 corner radius cutter machined the mid secton down to it’s final shape and finished by blending out the resulting facets with a fit of filing.

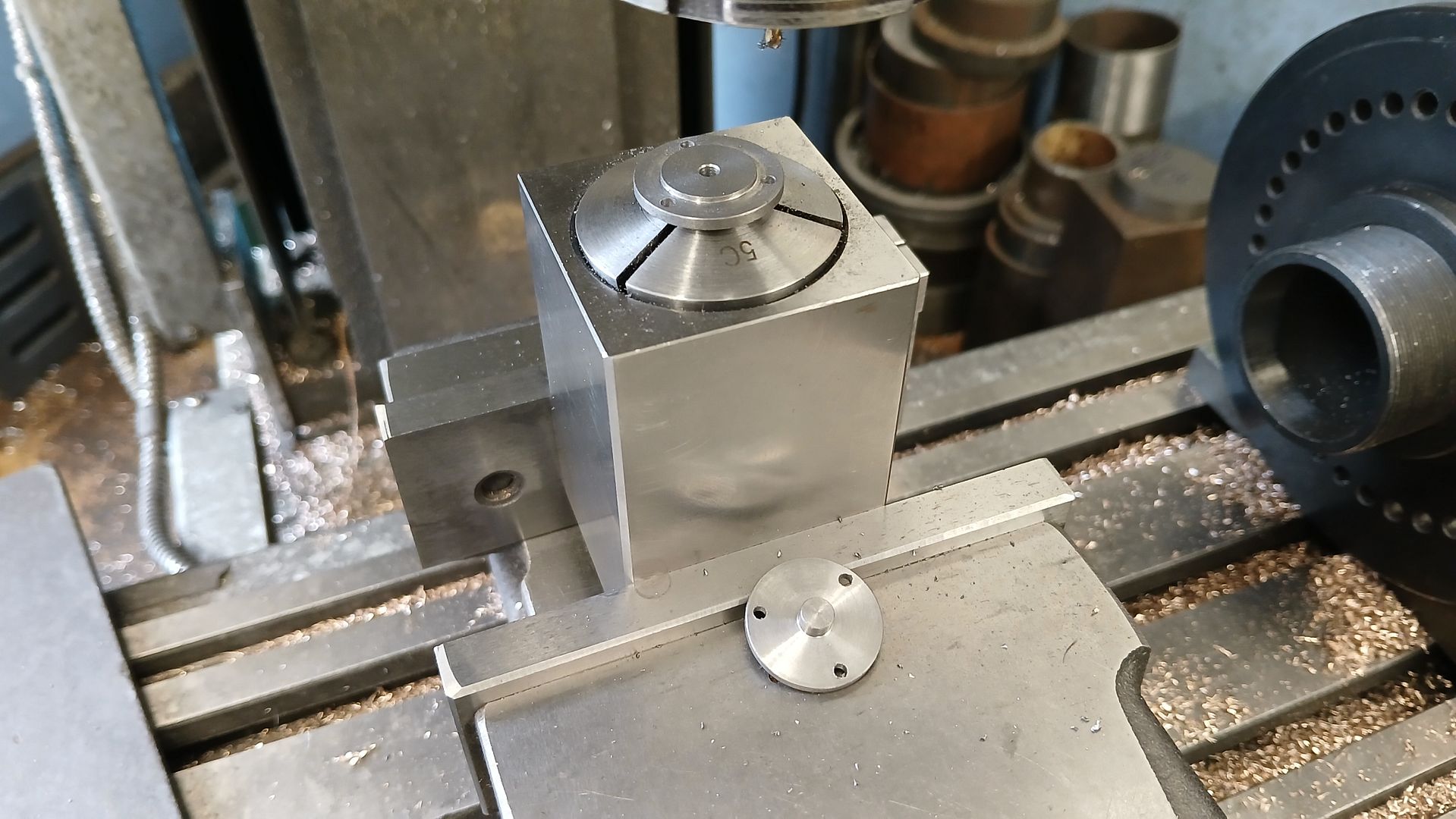

The two end covers were fairly straight forward, if small turning jobs from some offcuts of cast iron bar. held in a 5C collet block to drill the screw hole son their PCD.

Diogenes.