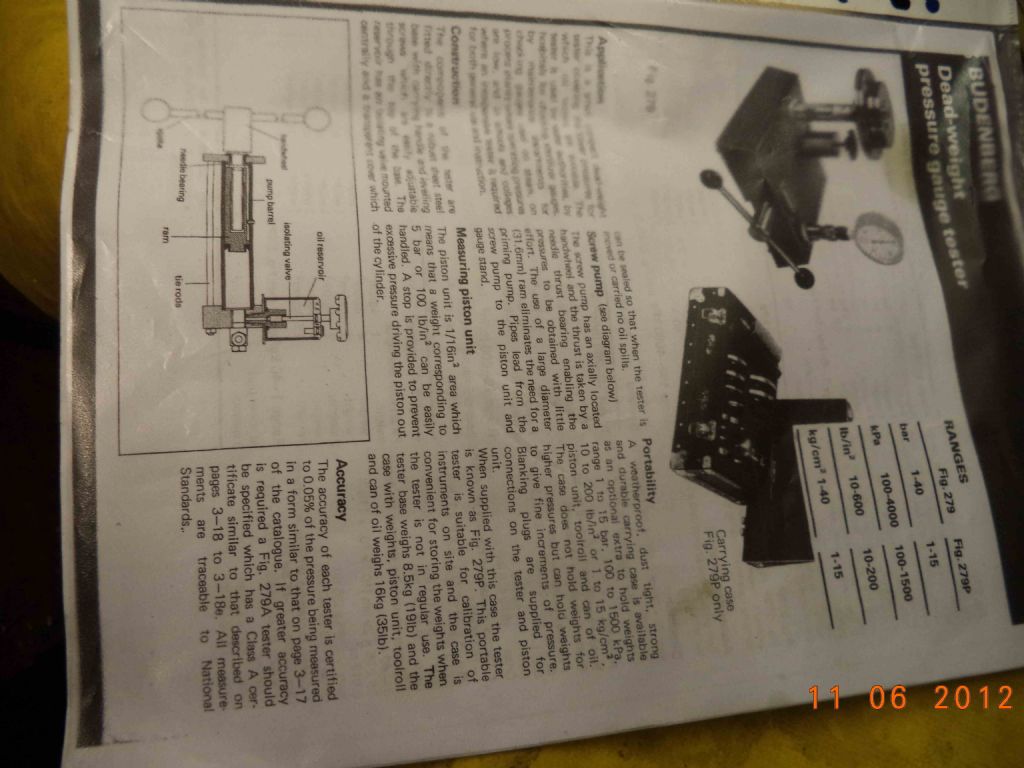

Budenberg Dead Weight Pressure Tester

Budenberg Dead Weight Pressure Tester

- This topic has 16 replies, 10 voices, and was last updated 27 January 2018 at 17:00 by

Howard Lewis.

Viewing 17 posts - 1 through 17 (of 17 total)

Viewing 17 posts - 1 through 17 (of 17 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Arc Euro Trade Ltd.

- My vise isn’t at 90 degrees

- Lathe index tips

- Hopeless…Alibre Ass

- Model Engine running just off a naked flame

- The Latest INDEX to Model Engineer & Workshop (Also past issues of MEW)

- Round Bar Bender

- Diving in to ATC?

- Edward Thomas excessive wheel slip

- Adding a quill lock to a drill press