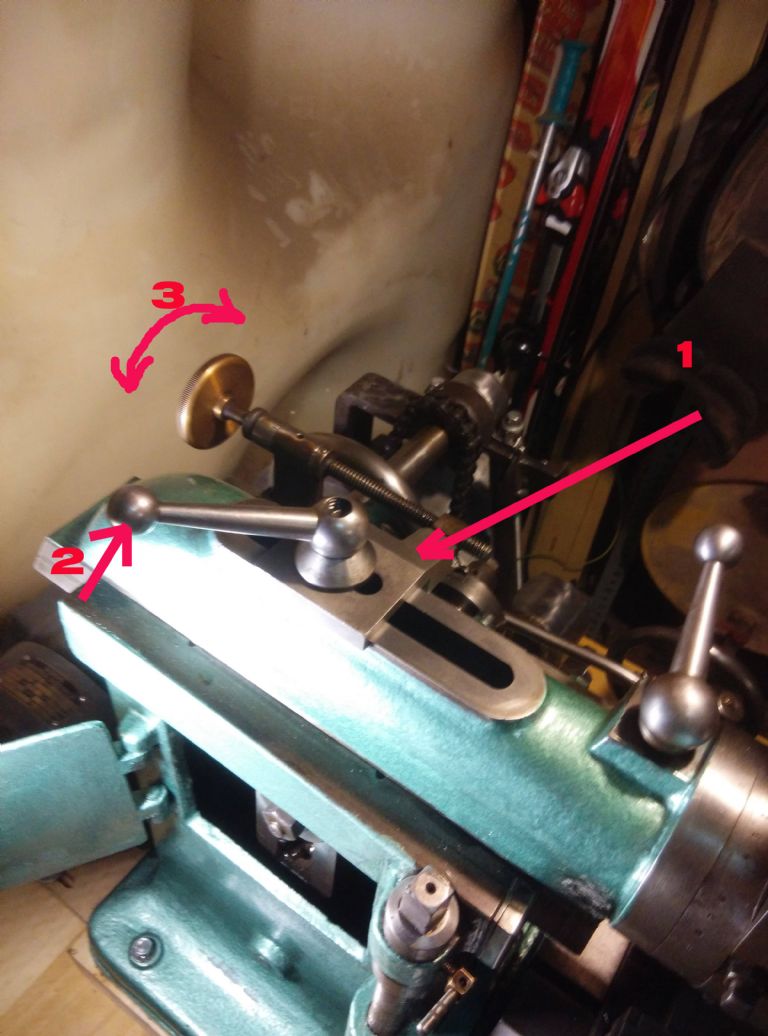

I reckon you've guessed right with what that screw drives, in those last photos, Jordi.

Why?

Definitions first:

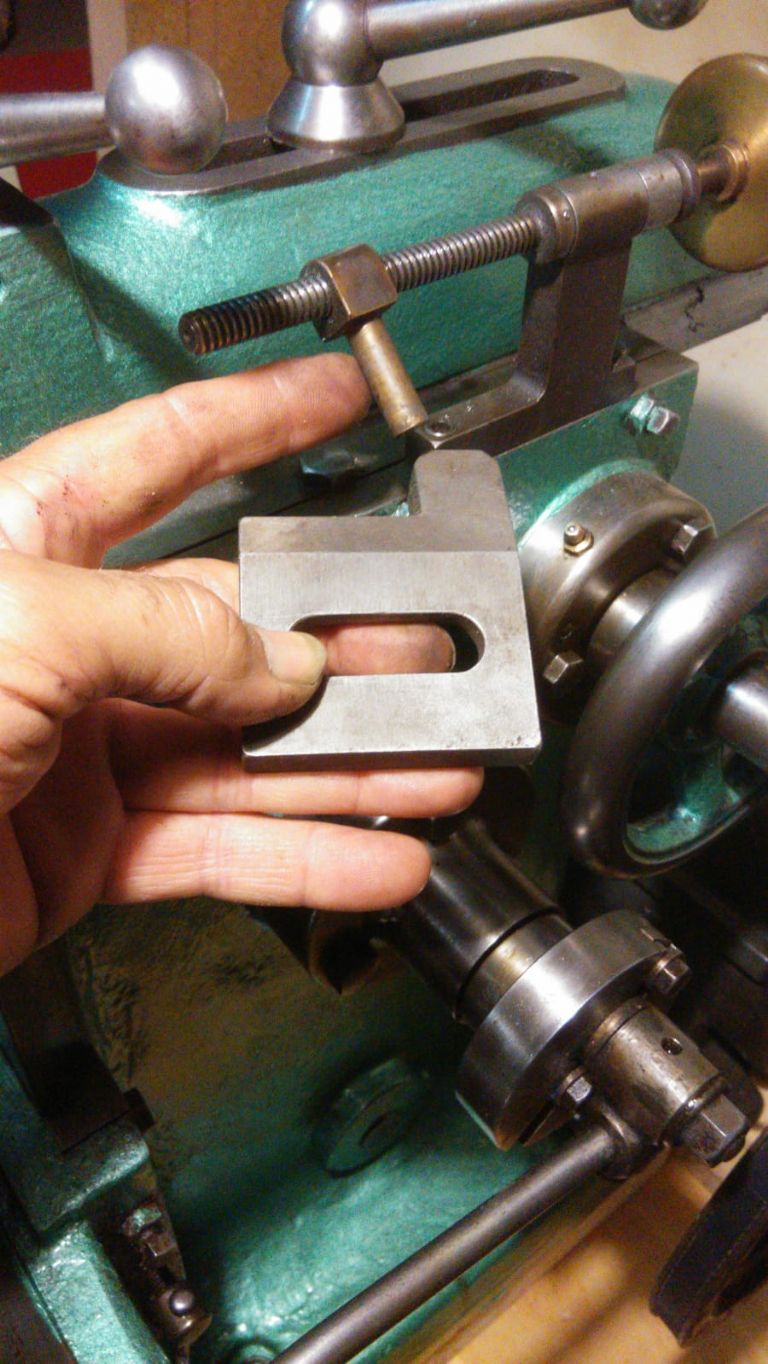

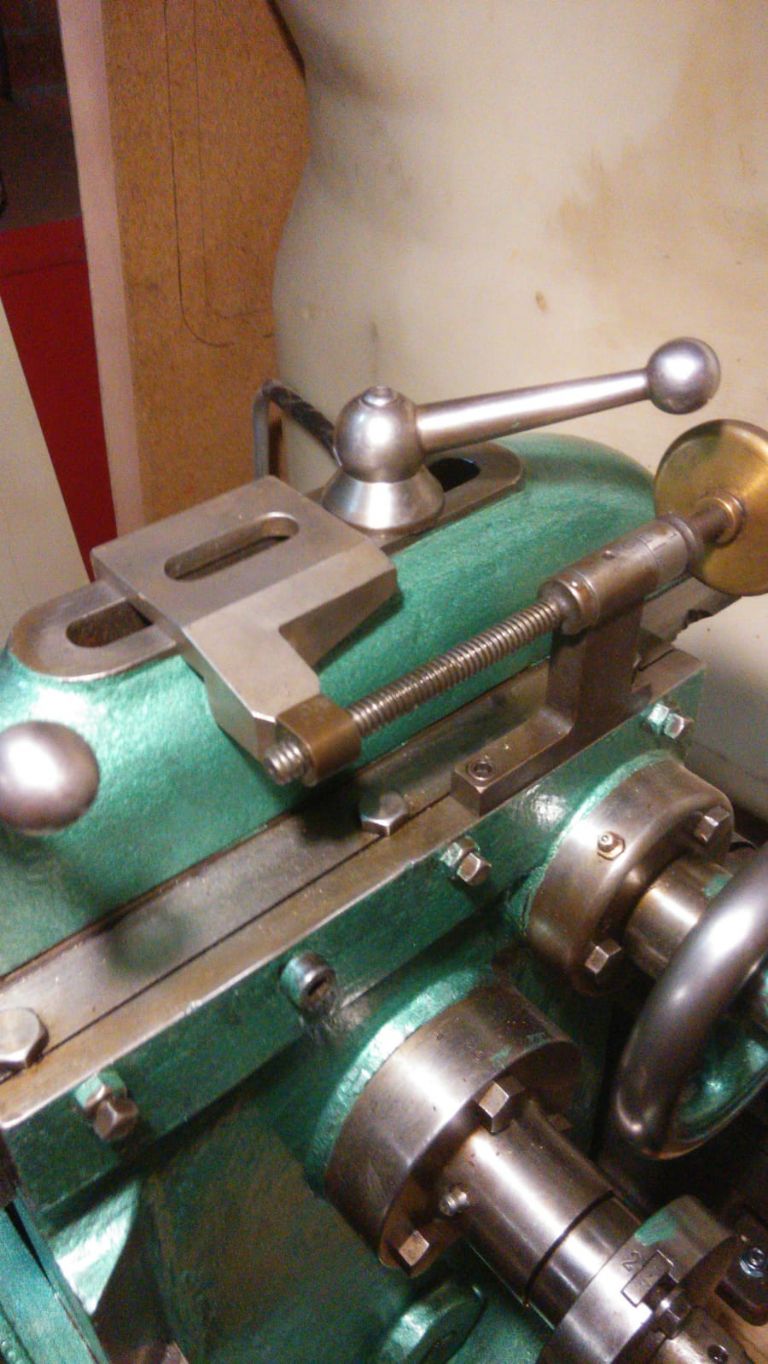

The sliding mass on the shaper is its Ram.

The Clapper-Box is as it says, the hinged block that holds the tooling.

That add-on does not reach the clapper box, and I can't see why you need to limit its return arc. In fact I'd consider that bad practice. You control the tool geometry by grinding it appropriately.

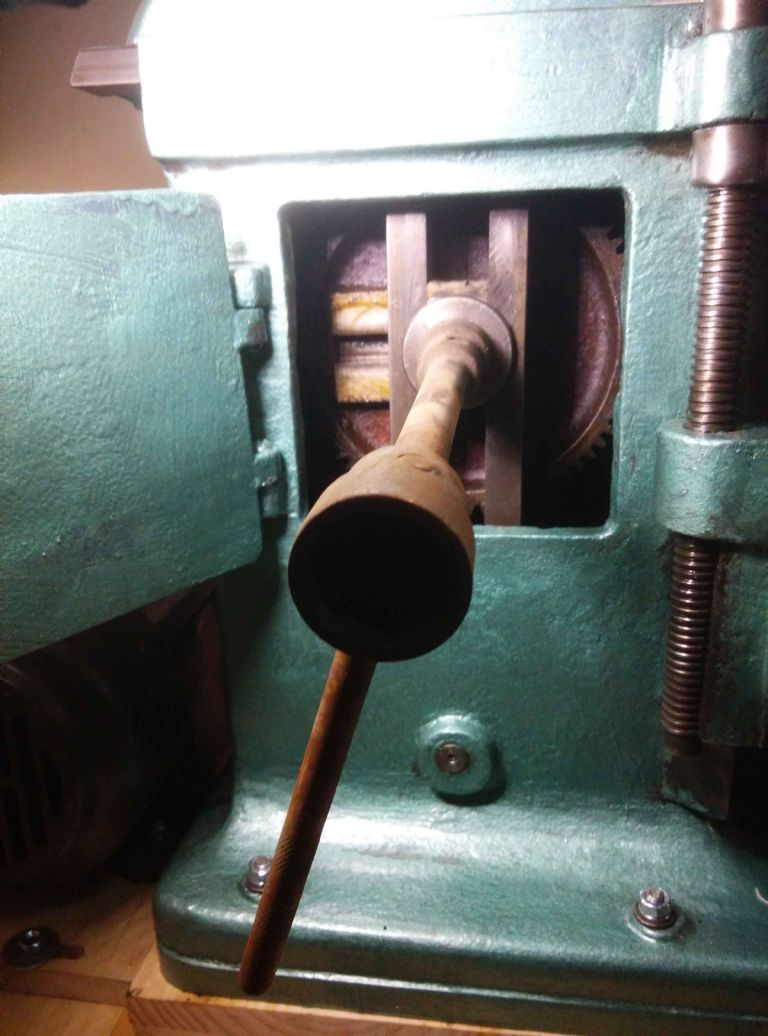

The only time you lock the clapper-box, is when cutting internal key-ways etc. Those are normally draw-cut, necessitating that locking. One way that avoids modifying the machine is to use a tool-holder fitted with a jacking-screw in an extension above the clapper-box top.

So why this accessory?

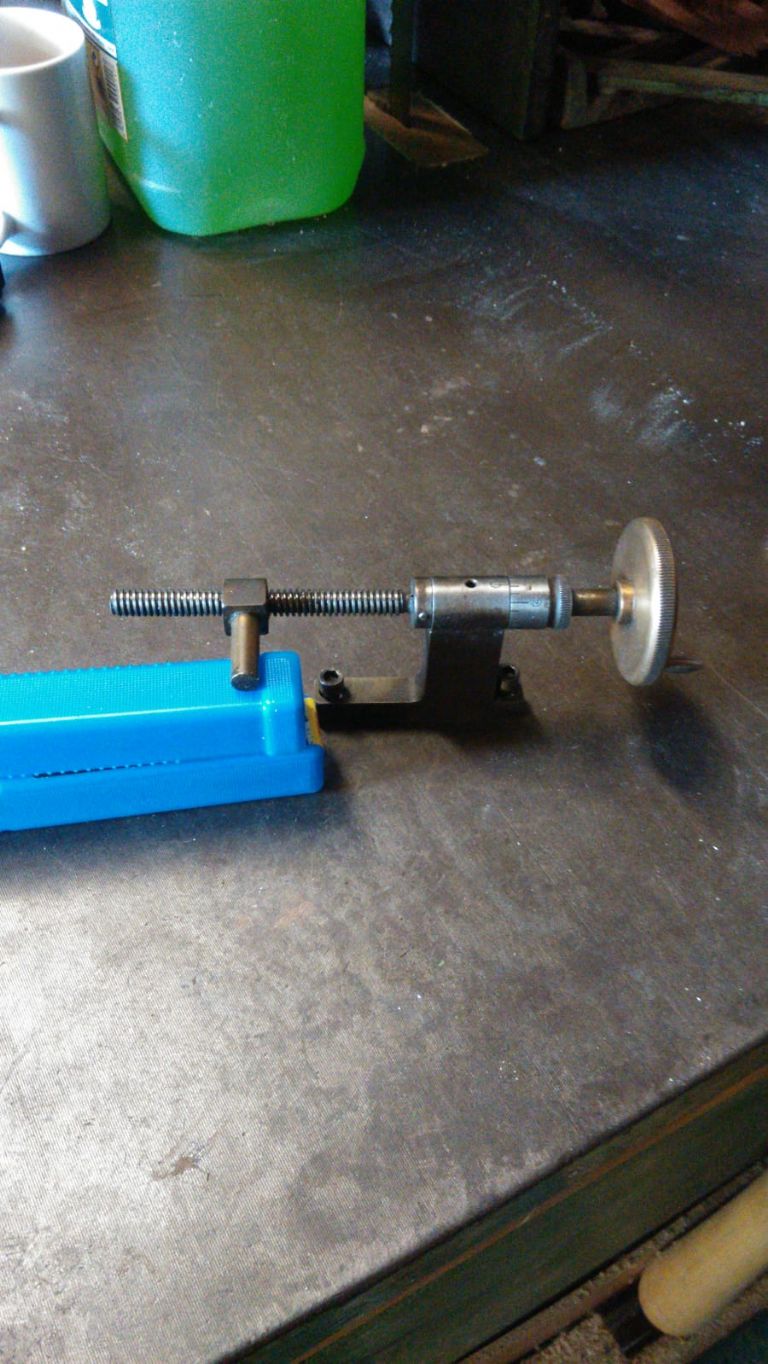

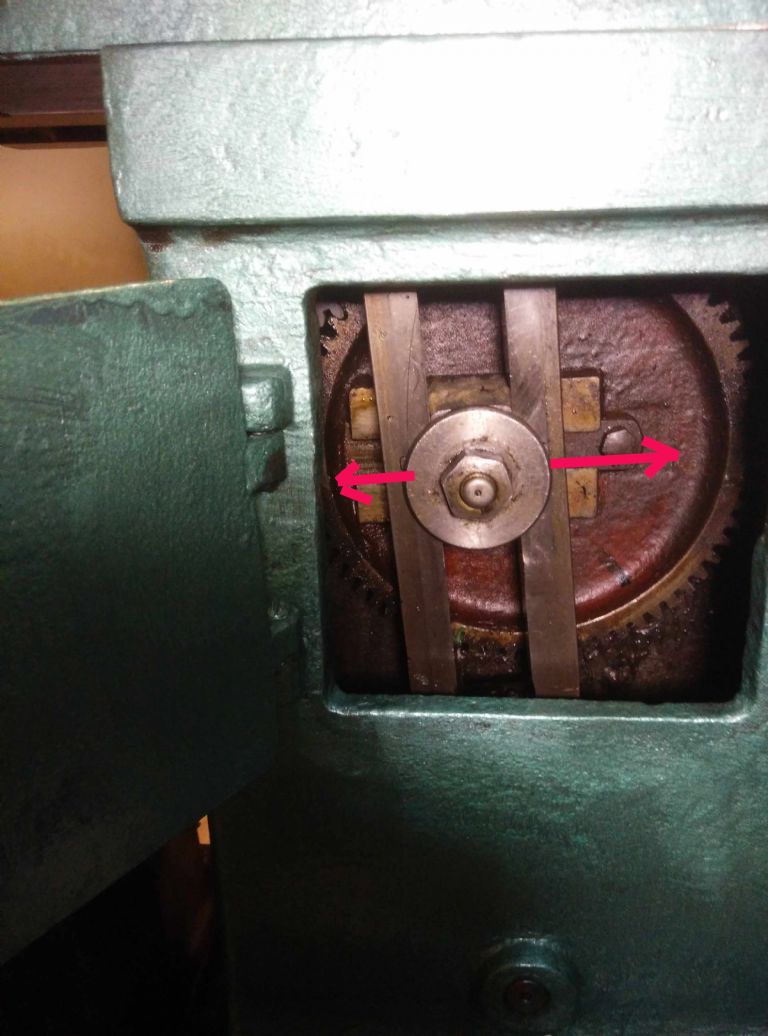

First what it is NOT. It is not a stroke-limiter – not on a power-driven machine! That is the task of the crank adjustments and nothing should obstruct the ram acting as the crank stroke and relative position give.

Therefore, I think it was intended to give a fine, short-stroke hand feed. Hard to see where that might be used, but one guess is for engraving scales when you'd want to cut only short, fine grooves under close control.

John Olsen.