Posted by old mart on 07/09/2020 15:29:04:

What I fail to see is how the average lathe owner would ever be able to make substancial modifications to his machine without first having the use of a much bigger one to make the parts…

By coincidence I'm reading ME3313 (January 1967) which encourages exactly that in an article by Martin Cleeve entitled 'Lathe Topics – Improvements to a 3 3/8" machine'. It turns out to be a Zyto.

Don't read on if you believe British made hobby lathes of yesteryear were of superior quality! Cherished illusions may be shattered. Mr Cleeve starts:

A majority of home mechanics who own the older type of lathe, and whose pocket will not stretch to a more modern machine, are nevertheless of a discerning nature. They may often feel dissatisfied with many of the fittings on their machine, thinking perhaps that the design and mechanical function is lacking in finesse and giving the impression that a breakdown may occur at any moment.

Vague mental pictures of desirable improvements are often formed, but these seldom crystallize into reality due to a subconscious feeling that to make improvements to actual components on the lathe, or to replace whole fittings with a completely new design would be impossible because the original was made in a factory with facilities for machining not available at home. But this is erroneous thinking for the following reasons.

These early lathes were built down to a price and the interest of the makers was in rapid production, not in ultimate ease of use, reliability or appearance. Even accuracy seemed to be largely superficial: if the tailstock was pointing approximately in the direction of the headstock, well that was good enough.

Indeed with some old lathes I have vetted there has been every evidence that assembly has been carried out by labourers who took no pride in their work and had no knowledge of engineering whatever except a screw is turned clockwise 'to do it up.'

Even the designers, in some cases, seemed to have only a vague idea of the functions of a lathe… Mr Cleeve provides another 5 paragraphs of design faults, before saying:

By my remarks on the shortcomings of these earlier lathes, I do not wish to convey the impression that those who cannot afford a modern one should go without until they can… by all means buy an old lathe – but do not be afraid to modify it.

Few old machines are so awful as to be incapable of making new components for themselves…

So good luck to Niels, upgrading lathes is respectable. Improving a Far Eastern lathe seems admirable to me, and even an unlikely failure wouldn't be the end of the world. Some jobs need a big spindle, so why not fit one if the headstock is beefy enough? Go for it!

Dave

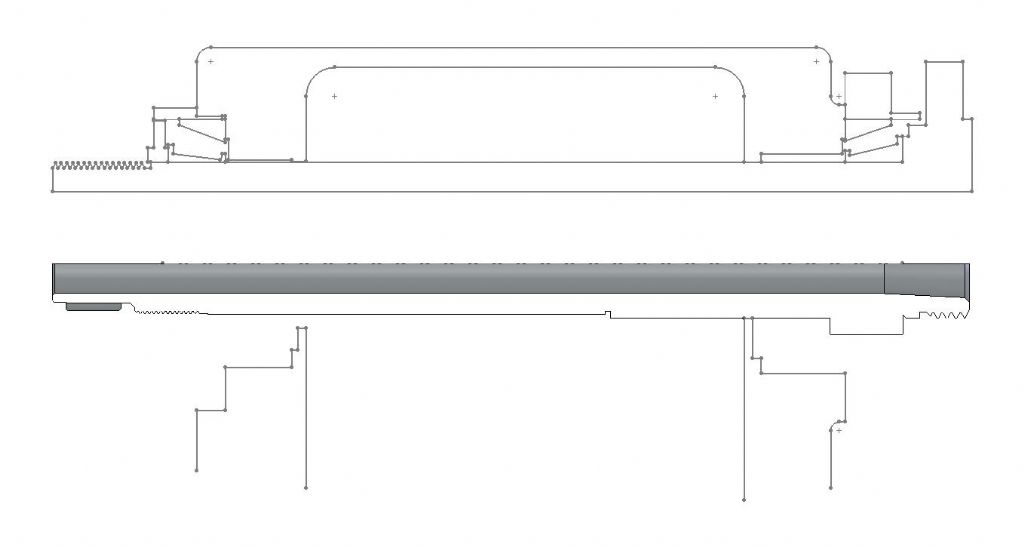

Niels Abildgaard.

![wp_20200905_006[1].jpg wp_20200905_006[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/875351.jpg)