I have been looking for one of these that I could afford for some time, as although on a good day I can cut through a 2" bar with a hacksaw, doing so would leave me completely paralysed for several hours afterwards. This one came up on eBay, and it appears to have been almost unused (it still had a Reyrolle plug), but has had a nasty bash at some point. The pivot pin and operating rod for the latch were both bent, the latch button was missing, and both the blade lifting handle and the power trip lever had been snapped off. Fixing the trip lever was a first priority so that it will turn itself off if I have an episode of paralysis.

There seems to be very little information on the "90" model on the web, so I thought I would post some pictures of the machine and the parts I made to repair it. The saw still needs a lot of cleaning, but apart from a little surface rust everything seems fine, and it can start work as soon as I make a space for it (I can see why the "60" is more popular). There is a publicity drawing of one on lathes.co.uk that appears to show a similar round motor to mine, as well as a round knob as the release button and some kind of sleeve or roller on the trip lever.

These are the parts I made, together with the original parts they replaced. The machine ball was easiest, as I only had to tap it out, but until I make a rotary broach, the pivot pin will have to make do with a hex head.

I couldn't work out how to spin rivet over the end of the trip lever to retain the delrin roller, so I made a separate cap and secured it with Loctite. I will probably remake this lever later as I gave it too much offset and it has to be installed at an angle to avoid hitting the belt guard when lifted.

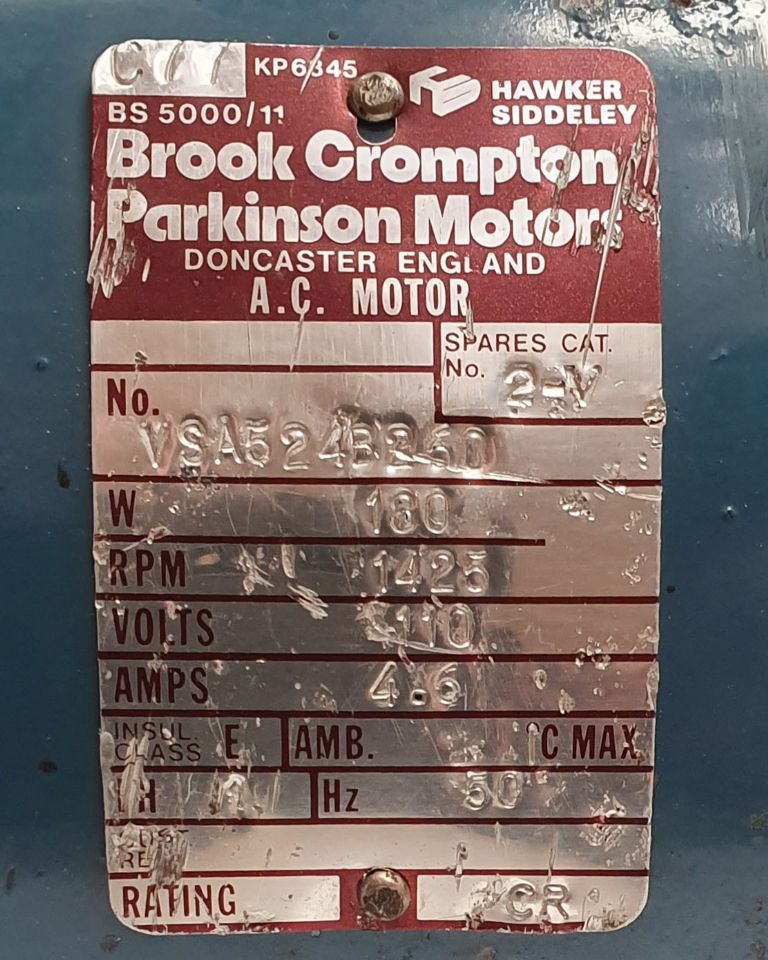

Here are a few pictures of the complete machine with the parts fitted. The motor is a mid-1970s Brook Crompton Parkinson, not Hoover or Lemac, and I have only found one picture of another Hexacut with this make of motor, so I don't know if it is original.

One oddity of the design is that the MEM NVR switch (which makes it really hard to set the depth stop) is upside down in order to be operated by the trip lever.

I had to fit a Kennedy blade

Thanks for putting up with me rambling on, hopefully the pictures will help anybody else with the same bits missing.

Brian

Baz.