I'm a great fan of the Huffam type wiggler for general use on my DRO equipped Bridgeport.

Given a modest level of care reliable sub-thou accuracies are routine. Maybe under half a thou if I concentrate. Using the 1/2 function of the DRO between two decent smooth surfaces, such as good vice jaws, suggests something around a couple of tenths of a thou. But how realistic that is in the real world given everything else that is going on is open to question. When you get down to that sort of precision variations in technique are seriously important.

A fair few years back I did some comparative tests against my nanometer sensitivity Hiedenhain probe which confirmed the Huffam was pretty darn good and very repeatable.

Unlike the cheap wiggler, probe and indicator holder collet set types the Huffam has a proper bearing surface for the ball to run against and a spring loaded nylon pusher to apply a constant, modest load. Internal frictional forces are both low and repeatable so the ball or cylinder contact probe is able to crawl sideways almost immediately on contact with the surface rather than needing a real offset as the cheaper ones do.

The collet held style wigglers have unavoidable friction so they need more offset to swing sideways. By dint of much patient playing in pre Huffam days I got my cheap set down to around 5 thou error on a good day. 10 thou is more realistic if you just assemble it. The needle pointer now lives permanently in my collet for when I have to pick up on lines and similar. Friction on the ball is an advantage there because the needle stays put when gotten to run true.

Converting an inexpensive wiggler set to Huffam style by making a new holder or two looks to be a relatively simple project and well worth the effort. Geo. H Thomas published a design for a complete unit whose holder could easily be adapted.

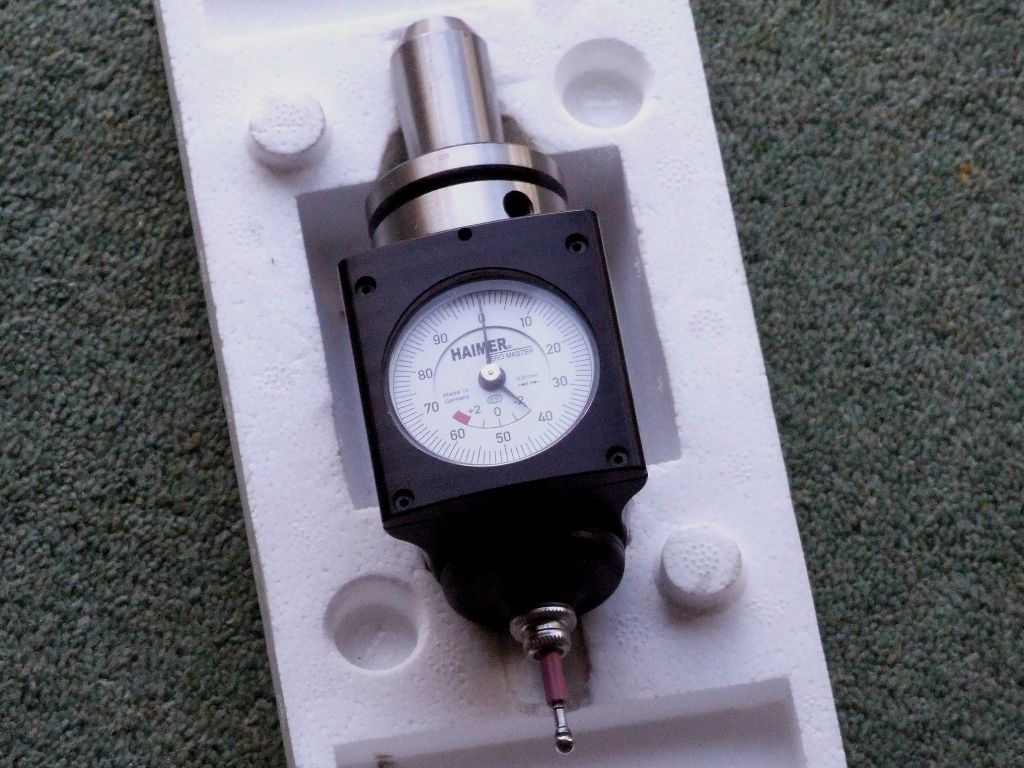

I have a Haimer like Andrews which I really must play with somewhen. Grabbed it 'cos the price was far too good to miss.

Clive

Edited By Clive Foster on 06/11/2020 22:54:24

Edited By Clive Foster on 06/11/2020 22:55:34

old mart.