Hey, Mark.

I appear to have been one of Mike's other guinea pigs for this new build.

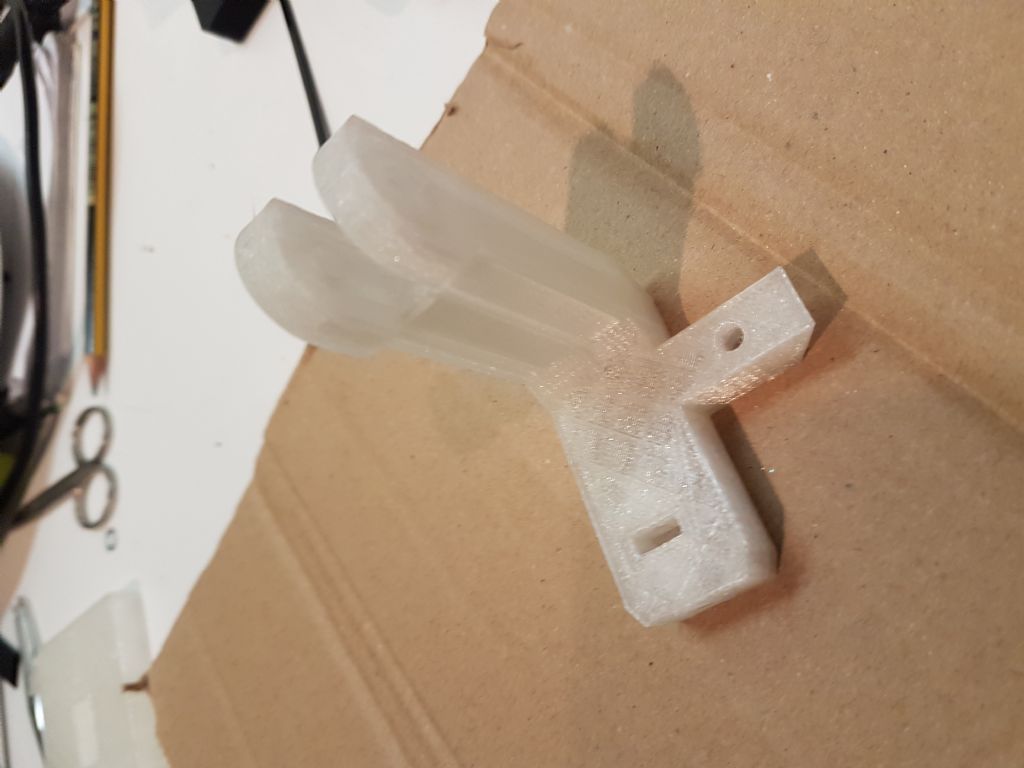

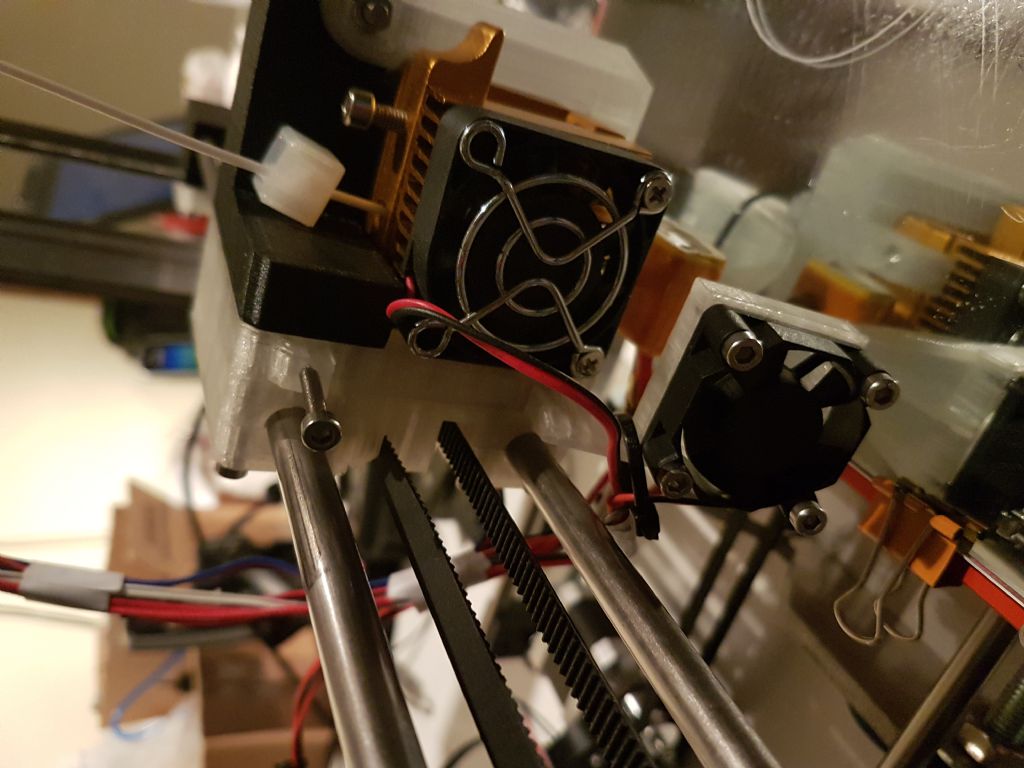

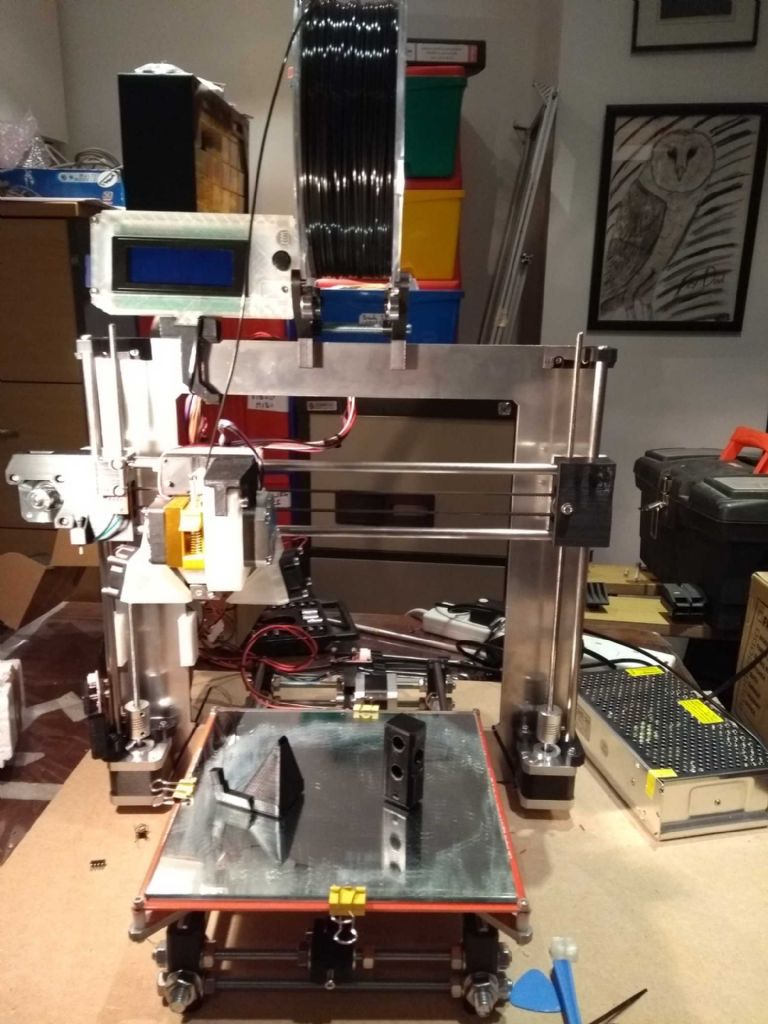

I too had trouble with the build fans. the wedge mount snapped off on one of them with little provocation and again on an early print. Superglue has come to the rescue both times, though I'm not sure I expect the repair to keep working. I've printed another mount for when that fails.

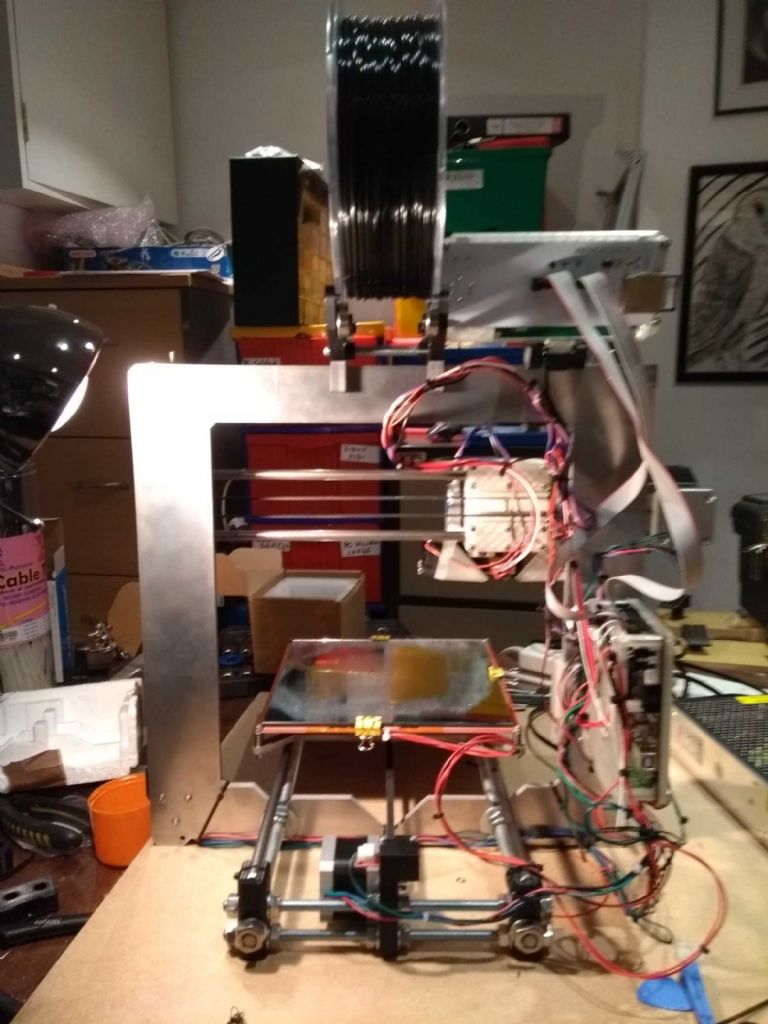

I had some issues with the electrics. the plugs don't really match the sockets and my last build issue turned out to be a bad contact on the Y motor.

I've managed to sort of tidy up the wiring with profligate use of cable ties, but I agree that it's not the nicest part of the kit. Nor did I entirely like the electronics box.

Throughout this (and most noticeably even over Xmas) MIke has been on hand with advice and support and appears to be taking all feedback very seriously.

I'm happy with my new machine, though I've still to find something I can make which will please her indoors. I have some ideas, but let's see.

Now for the struggles with the design and slicing software. Keeps you young (ish)…

Iain

Neil Wyatt.

Neil Wyatt.