Ian –

Only just spotted your post of 2 or 3 weeks ago, wondering if you can go and buy metal. This must be a problem for many of us.

I suppose you could have added it to a food-shopping trip, but would the place have been open anyway? The restrictions on driving are there to protect you, me the staff and everyone else, but if it's still open would it still be permissible to buy there on the principle that it is a shop still allowed to trade? The shop itself might have established a similar system to Screwfix: telephoned orders collected at the door. (Some pubs are selling their stocks rather like that – you collect the ordered beverages from a table outside the door.)

Some of our regular suppliers, including MJ Engineering and ArcEuro, have suspended trading but I bought some fastenings recently from Live Steam Models, by mail-order. Others may still be trading but their web-sites no longer work. I do hope we are all between us still supporting these firms as we can.

' ' '

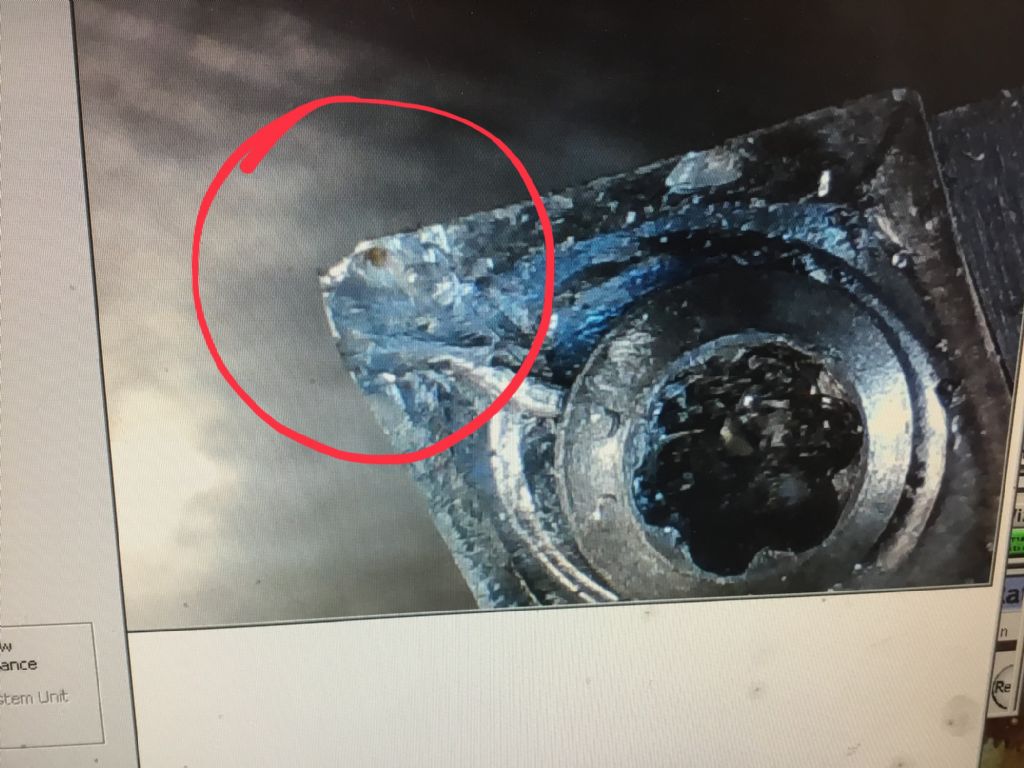

It's made me think carefully about the metal I have in stock. I've always used 'new-to-me' materials, but am presently using some steel that even I might otherwise scrap as it's so corroded.

It's a matter of cutting and machining the less affected metal to lose the worst pitting, and leave the remaining surfaces where it won't matter too much, and will be painted. Obviously those pitted surfaces are not on model components that will be visible so have to look right. Nor heavily-loaded, unless the steel is sufficiently over-size for cutting all surfaces below the corrosion. If loaded, I assess how it is loaded, and whether the weathering has weakened it too much for the application.

This is to leave my precious, non-precious metals in decent condition, for where original size and good surface condition are important.

Nigel Graham 2.