As my colleagues in China are all on holiday this week (Moon Festival) I've had a few half days off myself, which has allowed me to get some workshop time in. I'm getting better at this CAM / CNC stuff, notwithstanding the hamfisted idiot I share it with that runs amok in there from time to time and breaks all my tools.

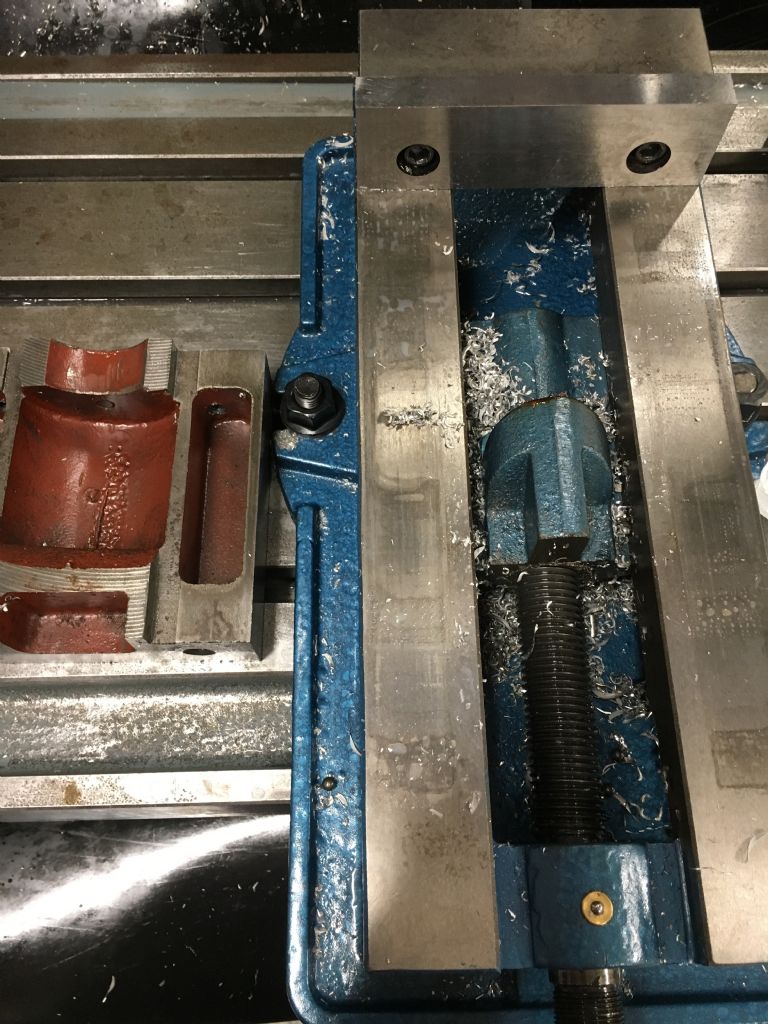

This morning I got the mamchine, tools and work (in the soft jaws) set up to finish the machining of my X axis housing. Just before lunchtime I was able to put on my rubber underpants and push the big green button. All went well and 26 minutes later this is what I got:

The setup time is coming down, as is the "paranoia time" spent double checking the tool lengths and stepping through the program on the machine. There's always room to cock something up but I'm finding it easier to set stuff up and convince myself it's looking good without wasting half of the day.

I have to say, even allowing for the CAM work and machine setup time, it would take me considerably longer to make this manually and it would end up with a few bodges along the way, speaking from experience. This is starting to make sense to me now.

As for Fusion 360, it has its differences from the likes of Solidworks etc but once you've got over that, the CAD and particularly the CAM are pretty straightforward and very capable indeed. The CAM for this only took me 20-30 minutes and I'd have done the CAD no matter how I'd planned to make it.

Murray

Another JohnS.