Used Lathe Pinnacle PL1340C Gap Bed

Used Lathe Pinnacle PL1340C Gap Bed

Home › Forums › Manual machine tools › Used Lathe Pinnacle PL1340C Gap Bed

- This topic has 109 replies, 25 voices, and was last updated 23 May 2020 at 12:28 by

SillyOldDuffer.

-

AuthorPosts

-

16 May 2020 at 15:54 #472183

Stuart Smith 5

Participant@stuartsmith5Posted by Ian Parkin on 16/05/2020 10:45:28:So was Stuarts post a typo about 180 degrees and 500v between phases rather than 415v ?

No, it wasn’t a typo. The split phase arrangement is used in some rural areas in the U.K. where there is only a single phase (2 wire) HV 11kV or 6.6kV overhead network available. It is now considered to be non-standard and only used when there is no alternative. For normal single phase supplies, a standard single phase transformer is used with a phase and either separate neutral and earth conductors or a combined neutral/earth conductor.

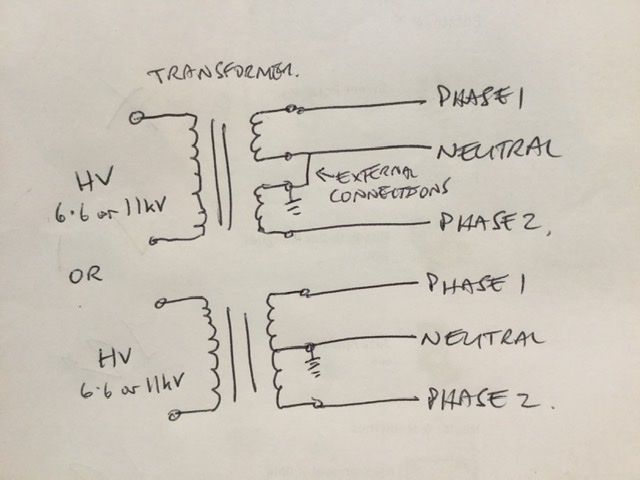

With a split phase network, a transformer with a single HV winding and either a centre tapped secondary winding or two separate windings connected as below:-

The neutral is common, but the two phases are 180 degrees apart. So between each phase and neutral you get a nominal 230v (actually up to 253 v depending on transformer tapping and voltage drops etc). Between the two phases you will get double this. In a single property, you could have say storage heaters on one and the rest of the house on the other ( with 2 consumer units).

In this case, running the workshop (with a single phase to 3 phase converter for the lathe) from one supply and rest of the property from the other.

Obviously in all cases needs there to be separation and labelling so that anyone doing work understands that there could be up to 500 volts between items on the 2 supplies.

Stuart

16 May 2020 at 16:13 #472190Anonymous

What Stuart says make sense. But the OP thinks he has something different, as he talks about the transformer taking two phases from the overhead? The voltage readings he gives for phase to neutral and phase to phase on the outpur don't seem to make sense for 2 phases of a 3-phase system or for the configuration elucidated by Stuart. May be it's a one off special?

Andrew

16 May 2020 at 16:30 #472194Stuart Smith 5

Participant@stuartsmith5Quotes from the OP:-

‘The 2 phases are coming in from a "split phase" transformer, taking the two phases from overhead, putting a meter across the two reads 445v, and each phase to neutral is 239. that is what i have, so any suggestions would be greatly appreciated.’ and ‘Just to say, the DNO people said when they were installing the power cable that it was a 2 phase supply, split 180 degrees apart on a center tapped transformer. hope thats of some help?’

Andrew

This is what I would expect with a split phase supply. Depending on the network voltage drops and loads, you could get anything from about 220v to 250v on each and 440v to 500v between the two. The discrepancy in each phase to neutral and between the two could be because the load and therefore voltage drops changed between readings or one of the phases has a higher load than the other because of other properties connected to the same transformer.

Stuart

Edited By Stuart Smith 5 on 16/05/2020 16:31:24

16 May 2020 at 17:02 #472201 SteviegtrParticipant@steviegtr

SteviegtrParticipant@steviegtrRobert lives in the Shetlands so guess that transformer type would be possible. Not the sort of thing you would find on a housing estate.

Steve.

16 May 2020 at 17:16 #472208Robert Laurenson

Participant@robertlaurenson59999Posted by Andrew Johnston on 16/05/2020 16:13:12:What Stuart says make sense. But the OP thinks he has something different, as he talks about the transformer taking two phases from the overhead? The voltage readings he gives for phase to neutral and phase to phase on the outpur don't seem to make sense for 2 phases of a 3-phase system or for the configuration elucidated by Stuart. May be it's a one off special?

Andrew

I do not think i have anything different, i have a 2 phase (Split Phase) supply from a center tapped transformer, the workshop is out in the rural part of shetland and no 3 phase overhead.

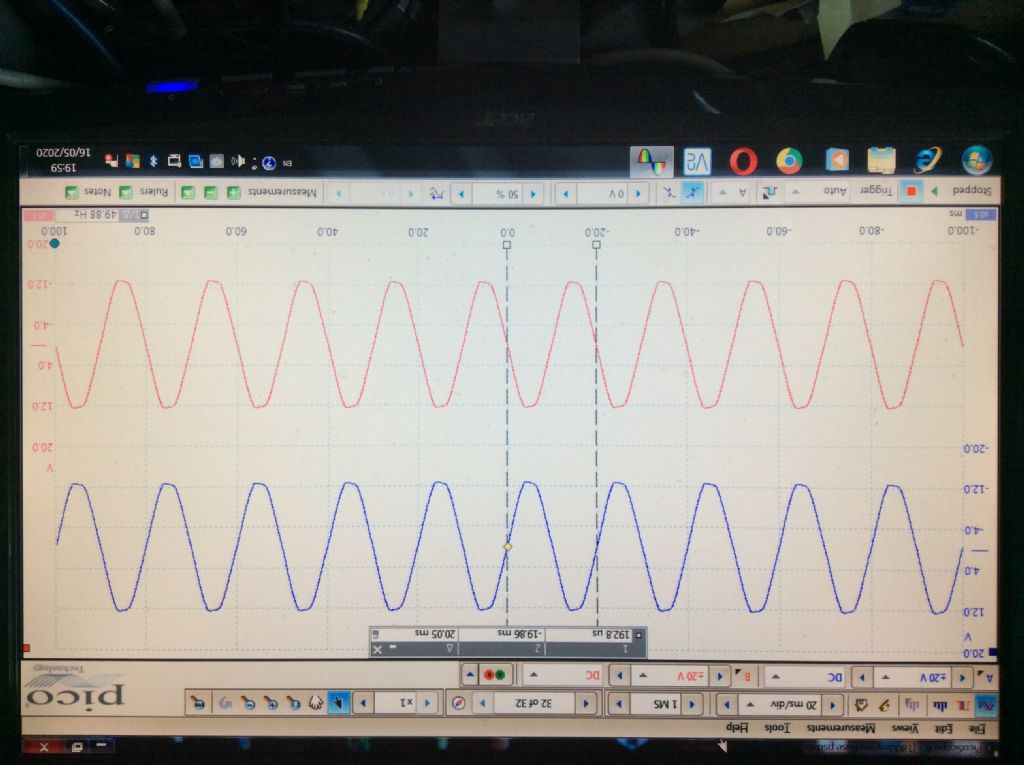

Just tested the voltages again, not sure if i got a duff reading the other day or was there a voltage drop at the time, but what i have now is 241 phase to neutral and 480v phase to phase.

A question for all of you, have any of you ever heard of the Unique 3 Phase system, an american guy with another take on the 3 phase conversion using a transformer and capacitors, (dont really know fully how it works but looks interesting)

Thanks

Robert16 May 2020 at 17:37 #472219Ian Parkin

Participant@ianparkin39383Stuart

so both phases are 180 degrees apart?

or in phase?

I can understand that both are at 240v relative to neutral

and 2x 240 =480 live to live but surely they will still be in phase

16 May 2020 at 18:08 #472227Anonymous

Posted by Robert Laurenson on 16/05/2020 17:16:44:Just tested the voltages again, not sure if i got a duff reading the other day or was there a voltage drop at the time, but what i have now is 241 phase to neutral and 480v phase to phase.

Those figures make more sense. So the transformer only takes one phase from the overhead as per Stuart's diagram, not two as originally stated?

Andrew

16 May 2020 at 18:15 #472228Robert Laurenson

Participant@robertlaurenson59999Posted by Andrew Johnston on 16/05/2020 18:08:42:Posted by Robert Laurenson on 16/05/2020 17:16:44:Just tested the voltages again, not sure if i got a duff reading the other day or was there a voltage drop at the time, but what i have now is 241 phase to neutral and 480v phase to phase.

Those figures make more sense. So the transformer only takes one phase from the overhead as per Stuart's diagram, not two as originally stated?

Andrew

Looking at the transformer (it supplies my workshop and 4 other houses) it seems to have a leg from each overhead line into the transformer, there are 2 lines overhead and both are connected into the top of the transformer as you look at it. so i assumed that it was a line from each, but i dont know.

As the DNO people said it is a single phase transformer with a center tapping so truly not sure what it is inside.

All i know is that i have two phases at my property, both on 100A cut outs and both 240 to neutral and 480 together.

Have you ever heard of this unique 3 phase transformer method of "converting" this type supply into 3 phase?

Thanks

Robert16 May 2020 at 18:46 #472237duncan webster 1

Participant@duncanwebster1If the Shetland electricity supply is the same as the rest of the uk the 2 phases are 120 degrees apart, just think of the transformer primary as being one leg of a delta connected 3 phase motor.

However I'm not clear where the 241/480 figures come from, should be 240/440 or thereabouts

16 May 2020 at 18:49 #472241Robert Laurenson

Participant@robertlaurenson59999Posted by duncan webster on 16/05/2020 18:46:32:If the Shetland electricity supply is the same as the rest of the uk the 2 phases are 120 degrees apart, just think of the transformer primary as being one leg of a delta connected 3 phase motor.

However I'm not clear where the 241/480 figures come from, should be 240/440 or thereabouts

As i mentioned above, the DNO people said that it was 2 phases from a center tapped transformer and that they were 180 degrees apart, i dont know why or the details of how it works but i have 240 / 480v and looking at forums in the UK it is'nt uncommon in rural areas.

16 May 2020 at 19:59 #472264 Robert Atkinson 2Participant@robertatkinson2

Robert Atkinson 2Participant@robertatkinson2This supply scheme is similar to that used in North America for domestic supplies. The NA one is 115V- 0-115V 180 degree phase shift to each house. It is used in some remote areas in the UK. Two wires are taken from the 3 phase high voltage (probably 11kV) supply and run to the remote location. Thi is of course single phase as there are only two wires. For each small group of consumers there is a transformer. In the simplest solution this would have a single 240 V (41.66:1 step down) output winding for the whole load at 240V. However the physics of transformer design means that a pair of windings connected 180 degrees out of phase use less core material. Splititng the load across two windings also means thinner wire can be used making winding easier. This scheme is called "Split-Phase" and uses a single (20.8:1 ratio) winding with a center tap. The center tap is the neutral for both supplies. Normally each consumer would only have a single 240V connetion but heavy users may have two. The voltage between the phases is 480V (if they were 120 degrees apart it would be 415V)

It is not possible to simply generate 3 phase from this type of supply. There may be confusion with two phase 90 degree systems (phase quadrature) which can be changed to and from 3 phase 120 degree using a pair of transformers in a arragement called Scott-T. To run a 3 phase motor you will need a converter either a electromechanical (e.g. transwave) or solid state (VFD) type. In theory you could feed a VFD with both phases via a pair of rectifiers but it's hardly worth it for such a small motor.Robert G8RPI.

16 May 2020 at 20:39 #472273Robert Laurenson

Participant@robertlaurenson59999Posted by Robert Atkinson 2 on 16/05/2020 19:59:10:This supply scheme is similar to that used in North America for domestic supplies. The NA one is 115V- 0-115V 180 degree phase shift to each house. It is used in some remote areas in the UK. Two wires are taken from the 3 phase high voltage (probably 11kV) supply and run to the remote location. Thi is of course single phase as there are only two wires. For each small group of consumers there is a transformer. In the simplest solution this would have a single 240 V (41.66:1 step down) output winding for the whole load at 240V. However the physics of transformer design means that a pair of windings connected 180 degrees out of phase use less core material. Splititng the load across two windings also means thinner wire can be used making winding easier. This scheme is called "Split-Phase" and uses a single (20.8:1 ratio) winding with a center tap. The center tap is the neutral for both supplies. Normally each consumer would only have a single 240V connetion but heavy users may have two. The voltage between the phases is 480V (if they were 120 degrees apart it would be 415V)

It is not possible to simply generate 3 phase from this type of supply. There may be confusion with two phase 90 degree systems (phase quadrature) which can be changed to and from 3 phase 120 degree using a pair of transformers in a arragement called Scott-T. To run a 3 phase motor you will need a converter either a electromechanical (e.g. transwave) or solid state (VFD) type. In theory you could feed a VFD with both phases via a pair of rectifiers but it's hardly worth it for such a small motor.Robert G8RPI.

Hi Robert

Thanks for the very detailed response.

That is fully understood, just out of interest, the Unique 3 phase book i mention has a reference to the very supply i have, and as far as i can make out it seems that the basic principle of the transformer is a basic transformer with 2 parts, 1 side being would to 240v, and the opposite side being wound with 3 seperate windings to 440v and the phase angle then corrected on the output with capacitors. I havent bought the book but from the research i have done it seems as though that is the basics of it.

In theory would that work? I mean from looking at his videos and reviews of the system it seems to work but im still not convinced enough to give it a go yet without advice from someone clued up on these type things?

Robert

16 May 2020 at 20:47 #472277 Nicholas FarrParticipant@nicholasfarr1425416 May 2020 at 20:47 #472278

Nicholas FarrParticipant@nicholasfarr1425416 May 2020 at 20:47 #472278Stuart Smith 5

Participant@stuartsmith5Ian

The voltages are 180 degrees apart because the opposite ends of the LV windings are connected to neutral ( and earthed at the transformer). So when the ac voltage in one winding is at its maximum positive value, the one in the other winding is at its maximum negative value (relative to the common neutral connection).

Andrew

Single phase distribution transformers are connected across 2 of the HV (usually 11kV or 6.6kV) phase conductors.

Duncan

My previous post explains how a split phase transformer is connected. It is not the same as 2 of the phases in a 3 phase system which are 120 degrees apart. This is not unique to the Shetlands and could be found anywhere where there is only a single phase (ie 2 wire) HV line. It is not that common, the standard supplies provided now are either single phase or 3 phase.

Robert

Even though the EU harmonised nominal voltage is now 230v, distribution transformers in the U.K. are still specified as 250 volts output for single phase transformers and 433/250 v for 3 phase transformers.

Stuart

Edited By Stuart Smith 5 on 16/05/2020 20:51:42

Edited By Stuart Smith 5 on 16/05/2020 20:52:20

16 May 2020 at 21:05 #472288Maurice Taylor

Participant@mauricetaylor8209316 May 2020 at 21:31 #472290 Robert Atkinson 2Participant@robertatkinson2Posted by Robert Laurenson on 16/05/2020 20:39:06:

Robert Atkinson 2Participant@robertatkinson2Posted by Robert Laurenson on 16/05/2020 20:39:06:Robert G8RPI.

Hi Robert

Thanks for the very detailed response.

That is fully understood, just out of interest, the Unique 3 phase book i mention has a reference to the very supply i have, and as far as i can make out it seems that the basic principle of the transformer is a basic transformer with 2 parts, 1 side being would to 240v, and the opposite side being wound with 3 seperate windings to 440v and the phase angle then corrected on the output with capacitors. I havent bought the book but from the research i have done it seems as though that is the basics of it.

In theory would that work? I mean from looking at his videos and reviews of the system it seems to work but im still not convinced enough to give it a go yet without advice from someone clued up on these type things?

Robert

Hi,

You can get any phase shift with an lnductor and capacitor with a fixed load. This is how the circuit you have seen works. Unfortunatly a machine tool motor is not a fixed load. The transwave and similar "converters" do this with component values for a typical motor and switched capacitor or taps for adjustment. It's not perfect but works. Often an unloaded motor is connected in parallel and turns all the time. It's inductance tends to swamp changes in the load reactance and it's rotating mass acts as an electrical flywheel.

With the current low cost of VFDs I don't see why anyone would bother with this type of converter, just use a single phase in 3 phase out VFD and leave it set to 50 or 60 Hertz if the machine or motor is not suited to variable frequency / speed.Robert G8RPI.

16 May 2020 at 22:18 #472301 SteviegtrParticipant@steviegtrPosted by Robert Atkinson 2 on 16/05/2020 21:31:16:Posted by Robert Laurenson on 16/05/2020 20:39:06:

SteviegtrParticipant@steviegtrPosted by Robert Atkinson 2 on 16/05/2020 21:31:16:Posted by Robert Laurenson on 16/05/2020 20:39:06:Robert G8RPI.

Hi Robert

Thanks for the very detailed response.

That is fully understood, just out of interest, the Unique 3 phase book i mention has a reference to the very supply i have, and as far as i can make out it seems that the basic principle of the transformer is a basic transformer with 2 parts, 1 side being would to 240v, and the opposite side being wound with 3 seperate windings to 440v and the phase angle then corrected on the output with capacitors. I havent bought the book but from the research i have done it seems as though that is the basics of it.

In theory would that work? I mean from looking at his videos and reviews of the system it seems to work but im still not convinced enough to give it a go yet without advice from someone clued up on these type things?

Robert

Hi,

You can get any phase shift with an lnductor and capacitor with a fixed load. This is how the circuit you have seen works. Unfortunatly a machine tool motor is not a fixed load. The transwave and similar "converters" do this with component values for a typical motor and switched capacitor or taps for adjustment. It's not perfect but works. Often an unloaded motor is connected in parallel and turns all the time. It's inductance tends to swamp changes in the load reactance and it's rotating mass acts as an electrical flywheel.

With the current low cost of VFDs I don't see why anyone would bother with this type of converter, just use a single phase in 3 phase out VFD and leave it set to 50 or 60 Hertz if the machine or motor is not suited to variable frequency / speed.Robert G8RPI.

To do that would he not require a single phase 240v in & 3 phase 400v out. The common ones only give 240v 3 phase out, hence the change to delta connection on dual voltage modern motors . The motor on Roberts lathe are 400v windings.

Steve.

16 May 2020 at 23:23 #472308Clive Foster

Participant@clivefoster55965Although the Unique transformer type 3 phase converter system can be made to work its a boatload of effort to build. It also requires tuning for each motor and load range. For practical purposes its still a static converter but the transformer runs the capacitor at higher voltage so there is more headroom for things to work. Still objectively a piss poor system tho'. Everything I've read about it makes me wonder why folk would put about 4 times the effort into building one, see **LINK** , as it would take to get a rotary running decently. Realistically finding suitable components at a sensible price is going to be difficult these days. Rotaries are the default converter design for good reason.

The big problem with two speed motors and VFD units is that such motors are invariably 440 volt machines and off the shelf VFD boxes are 220 volt output. No one makes a factory voltage doubled unit.

So your options for the two speed motor on that lathe are :-

1) Modified voltage doubling VFD used either in plug and play mode running at a fixed 50 hz or as conventional VFD. Its expensive but effective and pretty much immune to mains supply issues but its a non standard unit and works its capacitors even harder than a normal VFD. The capacitors are consumable items, assume 10 year life. I'd not consider it except as a whole shop solution connected to several machines. My 10 hp and smoothing inductors plug and play set up is probably approaching £3,500 these days! A single machine 3 hp one maybe £700.

2) Rotary converter from Transwave or other reputable maker. Not as expensive but can have issues if the supply isn't as stiff and stable as you'd ideally like. Generally going a size larger than you'd prefer to choose fixes that but the unit uses more power to run itself. Again best if running several machines. In your situation I'd probably choose a 10 hp unit, overkill but certain to work and up for running other machinery. Pushing £2,000 tho'.

3) If you only need 440 volts for the lathe changing the motor and using a standard inverter would be cost effective. Consider a 6 pole, 1000 rpm nominal, 3 hp motor and inverter from someone like Inverter Drive Supermarket. Typical prices motor £200, inverter £150, switches in a box £30 so maybe £500 with VAT. The economical option. All off the shelf and robust against supply fluctuations. I like the Eaton DE1 inverters for this sort of thing as they are specifically intended for dead easy installation to replace contactors in single speed or a few switched speed applications. 6 pole motor gives you more oomph at low speed than a standard 4 pole.

I'd change the motor. Prices being what they are today I'm seriously considering changing some of my motors and dumping my big box for one standard inverter per machine!

Clive

Edited By Clive Foster on 16/05/2020 23:24:43

17 May 2020 at 07:08 #472326Robert Laurenson

Participant@robertlaurenson59999Clive / Robert

Again, thankyou for the detailed reply's, i have had a look at the link shared also.

The reason i am looking at the converter route is because of what i am planning to get in the future. Press Brake, Guillotine and other larger items like that, usually starting at around 5KW and as far as i know the VFD option isnt an option there?

So i guess it comes down to now looking at what you have written whether i go for a Digital voltage doubling VFD, or either buy or build a Rotary Converter to suit my workshop.

The reason i had my eye on the transformer model was the fact it would be basically noise free (maybe a humm in the corner) as opposed to a Rotary sitting there being noisy and using electric all the time.

Any idea roughly how much a lets say 18.5kw rotary would use when its just spinning in the corner?

Thanks

Robert

17 May 2020 at 09:46 #472347 Robert Atkinson 2Participant@robertatkinson2

Robert Atkinson 2Participant@robertatkinson2A good rotary converter would run about 95% efficency at rated load. Most of this will be fixed lossses such as bearing drag and windage. I woud expect that a 185kW convertey would consume about 1kW off load. However you need to think kVA too because that's what the electricity meter responds to and can be a lot higher for an off load motor

If you are going to be running 3 or 4 5kW machine tools at the same time you should probably get a 3 phase supply. Otherwise modern solid state converters are probably the best solution. You don't HAVE to run a VFD att different frequencies, if you run it at 50 or 60 Hz it will run any machine if the voltage suits the motor.

The issue many have mentoned is getting a "400" volt output. from a 240V input. There a number of ways to do this. Easyist is a solid state converter specified for the task. These tend to be more expensive. As you have a 480V supply and a 3 phase in 3 phase out VFD converts it's input to DC it is entirely possible to use an exernal rectifier and filter capacitor to feed the VFD's DC bus. If the DC bus will take 680V DC you can use the 480V supply directly. Otherwise you need to drop the voltage closer to 418AC / 580DC. Two standard 30V dual secondary 500VA transformers wired in buck will drop you 480V to 420V.However doing this requires some knowedge of power electronics and motors. The easy / safe solution is Clives number 3 suggestion to change the motor and use a VFD. It will pay for itself in power bill savingscompared to a rotary converter over the years and make the lathe more saleable of you don't keep it.

The same goes for other 3 phase machines. Try to buy one with a low voltage or Star/Delta motor or just change it. Don't forget you can sell the old motor to get some cost back.

I would not consider a rotary converter unless it was free and preferably delivered for free.

Robert G8RPI.

Edited By Robert Atkinson 2 on 17/05/2020 09:48:14

17 May 2020 at 09:47 #472348Clive Foster

Participant@clivefoster55965Robert

One hears tales of rotary converter efficiency being in the 80% to 90% range with idling power consumption in the 5% to 10% range. Given the number of variables and interactions involved I guess its one of those "it all depends" things. Seems reasonable to expect your proposed 18.5 kw rotary to cost in the region of £5 to £10 per 40 hour week just spinning in the corner.

However the world is changing and I'd strongly urge you to set out a spreadsheet and do the maths for various combinations of supply devices for your machines with particular attention to how long you are going to be using the power hungry ones for. If the hard ones are only going to run for half a day a week in one continuous batch of work getting a used diesel powered gen set just for those might make a lot of sense.

I believe some 3 phase VFD boxes can accept a single phase input if derated. Still needs a transformer to boost your voltage or, possibly, they can use your split single phase set-up to get the voltage. Time to talk to the specialists and find out what can be done and how much it will cost.

My feeling is that one VFD per machine is now the bench mark for costing in smaller workshops, say up to 10 machines, if proper 3 phase power cannot be got.

Certainly when I put my big VFD box in back around 2006/07 (as a temporary expedient pending getting proper 3 phase laid in) because the small pseudo rotary I was using didn't have the power for more machines that or a similar size rotary for whole shop powered were the only viable options. One VFD per machine would have been impossibly expensive.

Fast forward to 2020 I have now got a 3 phase incomer but the professional electrician installation costs, extra components and commissioning charges aren't greatly dissimilar to going one VFD per machine, I have 10, even factoring in a couple of motor changes. I may well just choose to write off the new incomer costs. Especially as getting a sparky to actually turn up and do the 3 phase installation job seems to be impossible.

Clive

Edited By Clive Foster on 17/05/2020 09:50:57

17 May 2020 at 10:10 #472355Robert Laurenson

Participant@robertlaurenson59999Posted by Robert Atkinson 2 on 17/05/2020 09:46:47:A good rotary converter would run about 95% efficency at rated load. Most of this will be fixed lossses such as bearing drag and windage. I woud expect that a 185kW convertey would consume about 1kW off load. However you need to think kVA too because that's what the electricity meter responds to and can be a lot higher for an off load motor

If you are going to be running 3 or 4 5kW machine tools at the same time you should probably get a 3 phase supply. Otherwise modern solid state converters are probably the best solution. You don't HAVE to run a VFD att different frequencies, if you run it at 50 or 60 Hz it will run any machine if the voltage suits the motor.

The issue many have mentoned is getting a "400" volt output. from a 240V input. There a number of ways to do this. Easyist is a solid state converter specified for the task. These tend to be more expensive. As you have a 480V supply and a 3 phase in 3 phase out VFD converts it's input to DC it is entirely possible to use an exernal rectifier and filter capacitor to feed the VFD's DC bus. If the DC bus will take 680V DC you can use the 480V supply directly. Otherwise you need to drop the voltage closer to 418AC / 580DC. Two standard 30V dual secondary 500VA transformers wired in buck will drop you 480V to 420V.However doing this requires some knowedge of power electronics and motors. The easy / safe solution is Clives number 3 suggestion to change the motor and use a VFD. It will pay for itself in power bill savingscompared to a rotary converter over the years and make the lathe more saleable of you don't keep it.

The same goes for other 3 phase machines. Try to buy one with a low voltage or Star/Delta motor or just change it. Don't forget you can sell the old motor to get some cost back.

I would not consider a rotary converter unless it was free and preferably delivered for free.

Robert G8RPI.

Edited By Robert Atkinson 2 on 17/05/2020 09:48:14

Robert

Thanks for the suggestions, and i am taking note of all this.

The Lathe motor yes it would be no problem, not a big motor so getting one that can be run on a VFD or even a single phase one wouldn't be an issue, just had a look at the other equipment i would need in the future and it comes down to the press brake, i see no real way of getting one of those running on single phase even with a vfd due to the size of the motors on them, they are 5kw minimum, unless as you say i run a VFD from the 480v supply, can this definitely be done? was something i was thinking about but i just didnt want to waste money trying it to be honestIn the case of a vfd powered by 480v with 440 coming out of it or there abouts, would i then be able just to plug the machine directly into the VFD same as is done with the Drives Direct one?

Thanks

Robert17 May 2020 at 10:11 #472357Robert Laurenson

Participant@robertlaurenson59999Just to add, the 3 phase option from the network has been considered, and i got a price for it when installing the split phase, it was £25,000 pounds, 1 mile of overhead cable and supports, new transformer and obviously the time. so that was quickly put to bed as a no go option.

17 May 2020 at 10:16 #472358Robert Laurenson

Participant@robertlaurenson59999Posted by Clive Foster on 17/05/2020 09:47:47:Robert

One hears tales of rotary converter efficiency being in the 80% to 90% range with idling power consumption in the 5% to 10% range. Given the number of variables and interactions involved I guess its one of those "it all depends" things. Seems reasonable to expect your proposed 18.5 kw rotary to cost in the region of £5 to £10 per 40 hour week just spinning in the corner.

However the world is changing and I'd strongly urge you to set out a spreadsheet and do the maths for various combinations of supply devices for your machines with particular attention to how long you are going to be using the power hungry ones for. If the hard ones are only going to run for half a day a week in one continuous batch of work getting a used diesel powered gen set just for those might make a lot of sense.

I believe some 3 phase VFD boxes can accept a single phase input if derated. Still needs a transformer to boost your voltage or, possibly, they can use your split single phase set-up to get the voltage. Time to talk to the specialists and find out what can be done and how much it will cost.

My feeling is that one VFD per machine is now the bench mark for costing in smaller workshops, say up to 10 machines, if proper 3 phase power cannot be got.

Certainly when I put my big VFD box in back around 2006/07 (as a temporary expedient pending getting proper 3 phase laid in) because the small pseudo rotary I was using didn't have the power for more machines that or a similar size rotary for whole shop powered were the only viable options. One VFD per machine would have been impossibly expensive.

Fast forward to 2020 I have now got a 3 phase incomer but the professional electrician installation costs, extra components and commissioning charges aren't greatly dissimilar to going one VFD per machine, I have 10, even factoring in a couple of motor changes. I may well just choose to write off the new incomer costs. Especially as getting a sparky to actually turn up and do the 3 phase installation job seems to be impossible.

Clive

Edited By Clive Foster on 17/05/2020 09:50:57

Thanks Clive

Good suggestions also and this possibility of starting with the 480V through a VFD may be my best option. The gen set idea i considered also, and for the initial outlay to get one big enough, and the fact you would then have to maintain it i quickly decided that wouldnt be the ideal option either.From all this discussion i now am thinking that putting 480v into a vfd and getting 415 3 phase out the other end (if its do-able) will be my best option, but what i wonder now is, if i do this and then have a 415v supply coming straight out of the vfd, can i then use this to directly power my machine as if it was plugged in?

Thanks

Robert17 May 2020 at 10:55 #472369SillyOldDuffer

Moderator@sillyolddufferPosted by Robert Laurenson on 17/05/2020 07:08:53:

…

The reason i am looking at the converter route is because of what i am planning to get in the future. Press Brake, Guillotine and other larger items like that, usually starting at around 5KW and as far as i know the VFD option isnt an option there?

So i guess it comes down to now looking at what you have written whether i go for a Digital voltage doubling VFD, or either buy or build a Rotary Converter to suit my workshop.

…

Any idea roughly how much a lets say 18.5kw rotary would use when its just spinning in the corner?

Thanks

Robert

A motor idling off-load will typically use 5 to 10% of it's rated power, so say about 1kW.

But maybe it's time to think about getting professional advice? The requirement has evolved from the best way to power a lathe that happens to have a VFD-awkward two-speed motor into a workshop containing several hefty 5kW items. This is crossing the great divide between a domestic set-up and a commercial operation.

In my single-garage workshop I've arranged the electrics around it's bog-standard domestic 13A supply. Although 26A is theoretically available because the socket is on a ring-main, I limit myself to running one machine at a time, and they are all sized within normal 240V 13A limits. This works well because it's just me, I never run my mill and lathe at the same time, and I doubt I ever consume more than 2.5kW peak (10A). My machines are either single phase or 3-phase provided by VFD. It's not complicated.

It wouldn't do if I was busy and especially not if two or more people needed to use a combination of machines at the same time. In my workshop the pillar drill, belt grinder, band-saw, grinding wheel, mill and lathe together are too much for my wiring. Introducing a high power, high-voltage, or dual speed motor into the mix would need special attention, either a posh-VFD (not ebay!), more likely a rotary. Wouldn't be difficult to uprate my workshop supply to say 30 or 40A, (say 10kW) but I'd need an electrician. Beyond 40A my consumer unit and company fuse would need to be upgraded too.

My garage workshop supply is OK for my amateur use. Cheap and straightforward, but limiting in use and difficult to expand beyond my simple needs. This sort of ad-hoc arrangement isn't a good way to power an expanding time-is-money business, for example staff queuing at machines due to power limitations wastes a fortune in wages. And, although the cost of the various single-phase to three-phase solutions are individually affordable step-by-step, the cost adds-up. There's a point at which it's cheaper to bite the bullet and have native 3-phase installed. Then powering 3-phase machines of any type ceases to be a problem.

The question is, how much would it cost to have 3-phase installed? Some forum members have had it done for perfectly reasonable money, others have been quoted ouch thousands. Seems to depend on how much work and disruption is involved, and if the benefit can be spread across other nearby consumers. Digging a trench along a busy 'A' road might be considerably more expensive than running overhead wires on existing poles to a new transformer. You would have to get a quote.

Tricky job starting a small business where the best must be made of limited resources. However, if the endeavour has a confident future and is going to expand, worth doing a Business Plan and, depending on the numbers, approaching the Bank for a loan.

Dave

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Manual machine tools › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Arc’s 25mm indexable end mills…

Started by:

gerry madden in: General Questions

- 9

- 12

-

4 September 2025 at 10:39

Julie Ann

Julie Ann

-

Parting off on a mini lathe

1

2

Started by:

Andy Brocklehurst in: Beginners questions

- 22

- 32

-

4 September 2025 at 10:29

JasonB

JasonB

-

Bridgeport Series 1, table power feed.

Started by:

Daedalus in: Manual machine tools

- 4

- 4

-

4 September 2025 at 10:28

Clive Steer

-

Alternatives for a DRO display change

Started by:

John Hinkley

in: General Questions

John Hinkley

in: General Questions

- 9

- 25

-

4 September 2025 at 04:40

Barry Smith 4

Barry Smith 4

-

Chimney turning

Started by:

dave22 in: Beginners questions

- 2

- 4

-

3 September 2025 at 22:39

noel shelley

-

Swing over bed limitation for flywheels

Started by:

Steve Huckins

in: General Questions

Steve Huckins

in: General Questions

- 15

- 22

-

3 September 2025 at 21:25

Engine Builder

-

An Unexpected Message

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 6

- 8

-

3 September 2025 at 21:12

Michael Gilligan

Michael Gilligan

-

Play on warco mini lathe saddle

Started by:

Michael Callaghan in: Manual machine tools

- 4

- 9

-

3 September 2025 at 17:50

Howard Lewis

-

Safe and secure way to suspend a 5″G Tender

Started by:

Greensands in: Locomotives

- 6

- 7

-

3 September 2025 at 14:51

Nealeb

-

Denford Orac refit

Started by:

Richard Evans 2 in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 5

- 19

-

3 September 2025 at 14:30

Stuart Smith 5

-

design and use of cutting tools

Started by:

john mostyn in: Books

- 8

- 9

-

3 September 2025 at 14:25

cogdobbler

cogdobbler

-

What Did You Do Today 2025

1

2

…

9

10

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 38

- 244

-

3 September 2025 at 13:05

Vic

Vic

-

Vallder CNC

Started by:

Michael Gilligan

in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

Michael Gilligan

in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 1

- 1

-

3 September 2025 at 08:38

Michael Gilligan

Michael Gilligan

-

Big Vise, go big or go home

Started by:

conrod in: Workshop Tools and Tooling

- 6

- 6

-

2 September 2025 at 20:00

old mart

-

St Albans Big Show 27 & 28 Sept 25

Started by:

Bazyle

in: Exhibitions, Shows and Club Events

Bazyle

in: Exhibitions, Shows and Club Events

- 2

- 3

-

2 September 2025 at 16:25

Bazyle

Bazyle

-

Exeter & District Model Engineers Show – 7 Sept

Started by:

Bazyle

in: Exhibitions, Shows and Club Events

Bazyle

in: Exhibitions, Shows and Club Events

- 1

- 1

-

2 September 2025 at 16:22

Bazyle

Bazyle

-

Task Light

Started by:

Vic

in: Work In Progress and completed items

Vic

in: Work In Progress and completed items

- 2

- 3

-

2 September 2025 at 15:15

Vic

Vic

-

alchin transfers

Started by:

joseph tatler in: Traction engines

- 4

- 4

-

2 September 2025 at 13:19

Clive Brown 1

-

Watercress Queen

Started by:

Diogenes in: Locomotives

- 3

- 3

-

2 September 2025 at 12:38

JA

JA

-

NU tool milling machine

Started by:

joseph tatler in: Manual machine tools

- 8

- 13

-

2 September 2025 at 10:31

joseph tatler

-

Newbie

Started by:

seanieboy in: Introduce Yourself – New members start here!

- 4

- 4

-

2 September 2025 at 10:25

Howard Lewis

-

Feed Water

1

2

Started by:

Richard Simpson

in: General Questions

Richard Simpson

in: General Questions

- 16

- 31

-

2 September 2025 at 09:44

noel shelley

-

Looking for a quality pencil sharpener

Started by:

Greensands in: The Tea Room

- 11

- 13

-

2 September 2025 at 08:56

Richard Simpson

Richard Simpson

-

Softening epoxy

1

2

Started by:

John Haine in: General Questions

- 23

- 42

-

2 September 2025 at 04:23

John Haine

-

Thread form of medical ‘screws’.

Started by:

JimmieS in: The Tea Room

- 7

- 11

-

1 September 2025 at 20:45

JimmieS

-

Arc’s 25mm indexable end mills…

-

Latest Issue

Newsletter Sign-up

Latest Replies

- Arc’s 25mm indexable end mills…

- Parting off on a mini lathe

- Bridgeport Series 1, table power feed.

- Alternatives for a DRO display change

- Chimney turning

- Swing over bed limitation for flywheels

- An Unexpected Message

- Play on warco mini lathe saddle

- Safe and secure way to suspend a 5″G Tender

- Denford Orac refit