As always with this sort of thing the devil is in the detail.

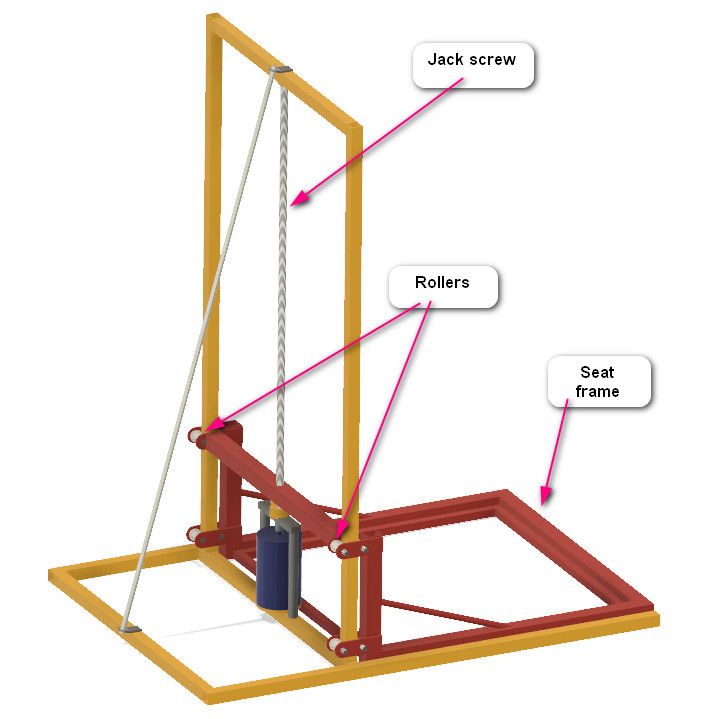

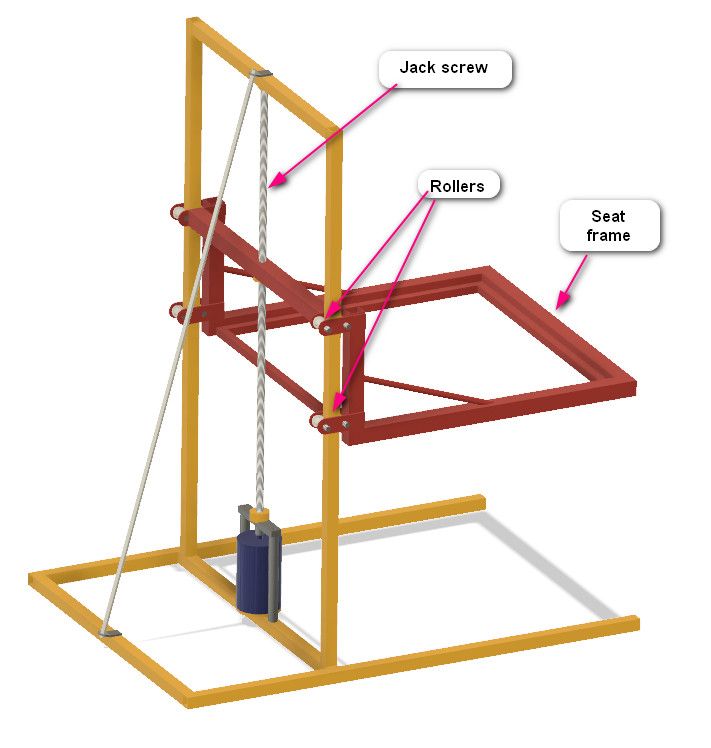

Delrin rollers should be OK. They work fine on the EazyRizer motorcycle lift which works on much the same principle albeit with single column upright and obviously stronger construction to cope with five times the weight. If I recall correctly from when I had one for about 3 weeks the rollers were rather larger than yours appear to be. If someone local has got an EasyRizer it might be worth looking at it for clues as to why yours doesn't work.

I recall coming across a reference somewhere to the relationship between roller size, loading and freeness of running which suggested that things go very nonlinear below about 1 1/2" diameter leading to much more friction than you'd expect if the design is little out.

I think the thing is twisting which will seriously increase the loads. Having hit that problem in a rather different area myself I think you need either 8 extra rollers to stabilise it in twist or to start over. That rectangular "doorframe" style upright is very flexible. A single, larger, column would be much better behaved.

I'd prefer a proper lead screw and nut to Allthread too.

Hafta say that the device reminds me of far too many episodes in the past where I "just built something simple to do an apparently simple job" rather than sitting down and designing it properly first. Result was always endless trouble getting it working properly. Easy to overlook simple but critical issues when your main attention is on the welding torch and chop saw! At 65 I'm finally getting a bit better but ….

Clive

Sam Longley 1.