Posted by Iain Pailing on 07/12/2018 20:50:26:

…

Am I doing something wrong or is it likely to be a problem with the lathe? Any thoughts would be welcome before I tear my hair out in frustration.

Normally I delight in pointing out the many ways in which the metric system is effortlessly superior to the inconsistent alternative. This isn't one of them!

For reasons I don't understand metric threads are defined in terms of pitch rather than turns per unit of measure. Although the two methods of defining threads are mathematically equivalent – pitch is the reciprocal of turns per unit measure – they are not mechanically equivalent.

In the imperial system (turns per inch) it's easy to arrange a gear against the leadscrew to drive a dial showing when the cutter is correctly placed to cut a thread. Not so on a metric lathe. Worse, the reason it doesn't always work isn't obvious, at which point hair tearing starts! On a metric lathe a single gear cannot represent all the required pitches.

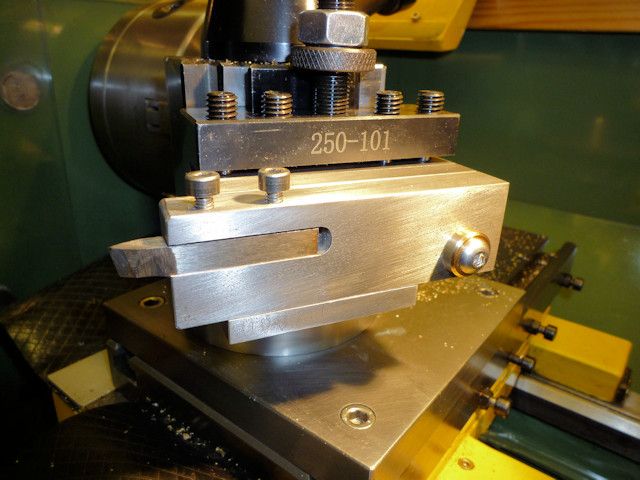

Some metric lathes, like my WM280, come with a single gear on the thread dial that doesn't cover all the possibilities.

Note the common pitches 0.7 and 1.5 aren't in the table. The lathe is perfectly capable of cutting them, what the table means is that the thread dial can't be used to reset the cutter, b*gg*r. A different technique has to be used. The easiest is to leave the half-nuts permanently engaged and drive the lathe in both forward and reverse as per Phil's post. Following advice received from Jason, I always cut threads in reverse because it avoids smacking the tool into the chuck at end-of-cut. The method works well when rewinding with closed half-nuts.

Some metric lathes don't bother fitting a thread dial at all, others come with a set of gears to cover all the common pitches (don't forget to fit the right one), some come with just one gear to cover common examples. Chinese lathes of which the WM family is typical might be a third case. The metric versions can cut a range of imperial threads and the imperial lathes can cut a range of metric threads. Such flexibility is very handy but a side effect is that application of the thread dial is less straightforward. As soon as you go metric watch out special cases and exceptions that the thread dial can't cope with.

Not your fault, or the lathe, but whoever decided to specify metric threads in terms of pitch. Does anyone know of a practical advantage gained by defining threads by their pitch? In comparison cutting TPI is a doddle.

Dave

Jon.