Well I had a measure up this morning, one result as expected the other two better than expected.

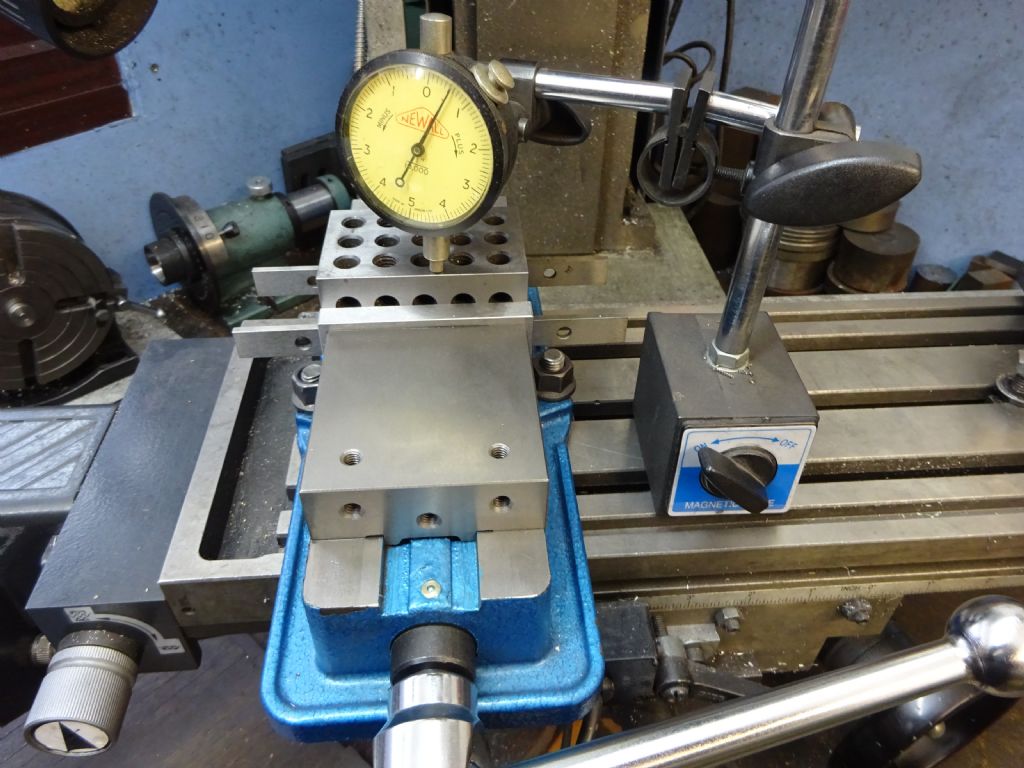

Basic set up was with 1/2" parallels and a 1:2:3: block clamping over the 2" width. I did it with vice bolted to mill table as that is how they are actually used and also allowed me to mount mag stand on the table as the smaller vices would not fit the stand on the actual vice as per the video. I also changed the moving arm on the DTI stand to a solid bar part way through as I thought the lack or reading may be flex in the arm. Newell 10ths dti and also tried with a 0.0005" lever type.

Basic set up shown

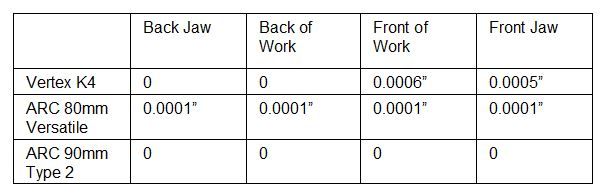

Results

I expected some lift from my K4 as it is the top screw type and has had 10yrs use, still quite good and nothing a tap with a copper or lead hammer won't cure. Back of fixed jaw is integral to the base so did not expect lift there.

The Versatile I could just detect some movement which considering the jaws screw to the base seems logical but plenty good enough for hobby use unless you are into splitting atoms in half on your mill.

90mm Type 2, again back and base are one bit of metal so did not expect movement there and the downward pull of the jaw must be working as the needles did not move.

So in my workshop they would all be fit for purpose and quite possibly better than a second hand one that has seen some use.

I did take a bit of video which I'll put together later but as it is a bit jumpy did not want to have Neil feeling sick after his New Year session!

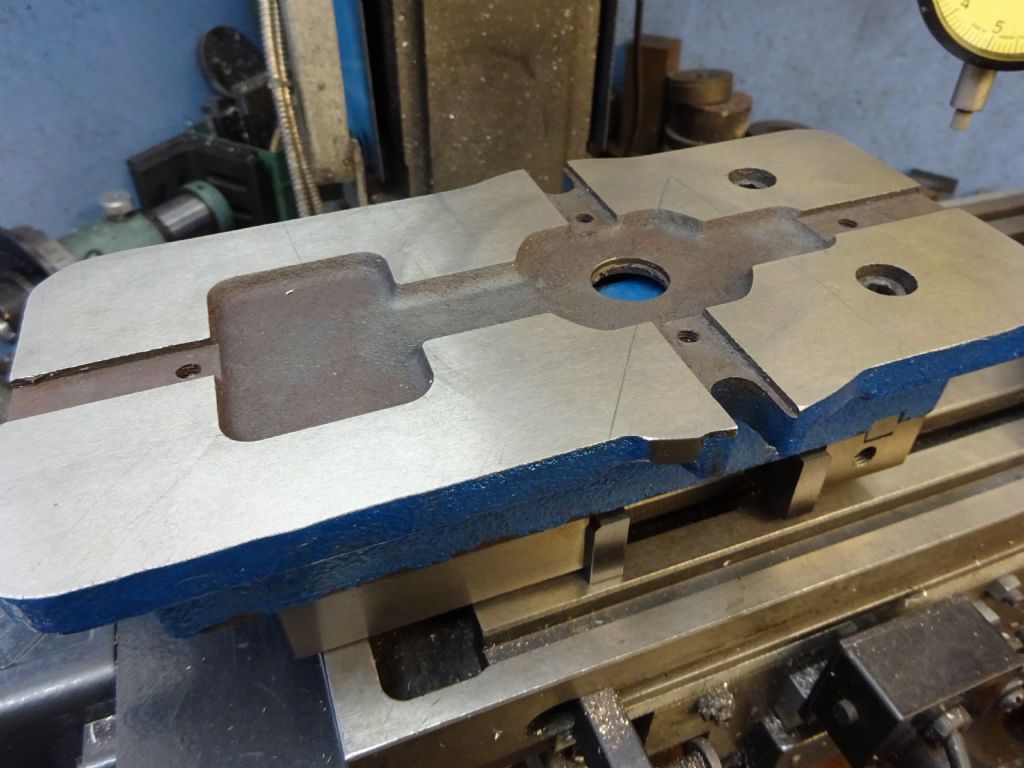

Also in the video he showed a step in the base where the casting looks to have just been face milled. The underside of the ones from ARC have a ground finish and I could not feel any ridges, that's why it is often better to get the item from a known supplier of good quality items that buy what looks to be the same from an unknown cheaper source as you never really know what you are getting from the web photos.

Edited By JasonB on 01/01/2018 10:30:54

SillyOldDuffer.