Bottom line with QC toolposts is that they have to be well and accurately made to function properly.

Piston types were generally considered the cheap option with constructional standards to match. Hence the bad reputation. Easily made to so-so quality but the dovetails have to be really accurately matched for best performance. Which never seems to be done. Locking device is inherently in compression too which amy not be the best idea.

Wedge type positively locks against one dovetail so is more tolerant of production errors. Ultimately not as strong as Dickson, Multifix, Tripan and the other less common industrial designs. But relatively easy to produce to a respectable standard without having to chase silly tolerances. Its become the budget choice for a reason.

Dickson are quite easy to make but do require the tolerances on the pull back locking set up to be held pretty tightly. Which far too many of the affordable clones don't bother with. Hence the bad reputation in certain quarters. The actual locating guide system on a Dickson is remarkably tolerant of errors and setting up for production is relatively inexpensive too which is why its so widely cloned. Possibly the strongest post design. Not that that will worry us. Worst thing about the Dickson is that the innards seem to be a magnet for fine swarf which, if allowed to build up too much, degrades the locking and rigidity. Easily stripped for cleaning so its no great trouble to scrub them out every year.

Multifix is the high end engineered system. Pretty much has to be well made to work at all so cheap clones generally don't exist. The Create version seems to be well thought of and is not impossibly expensive so its a safe choice. Will never be my choice as stripping to clean out is hard and I can't see the point of paying for 40 tool positions, 37 of which I will probably never use. Depends how you work.

Despite its popularity with the home build folk the Norman design is flawed. The solid rod post is the weakest of the common designs and overhang relatively large. Fundamentally its designed for treadle machines where cutting forces aren't huge. But its easily made and if you don't push the cut envelope it works well.

Most painful thing about QC systems is the near universal truism that you can never have enough tool holders. Seems to be accepted that 16 to 20 "will do for now". Ideally every tool should be in a holder ready for use. But who is in a position to drop £500 or £600 plus on their new QC set.

In my view the steadily increasing use of carbide insert tooling which doesn't need easy height setting to compensate for sharpening means its time to re-consider alternatives to conventional QC posts. Especially for home builds. Slotted block posts are easily made and, if easy to change, would be an acceptable alternative to conventional QC systems.

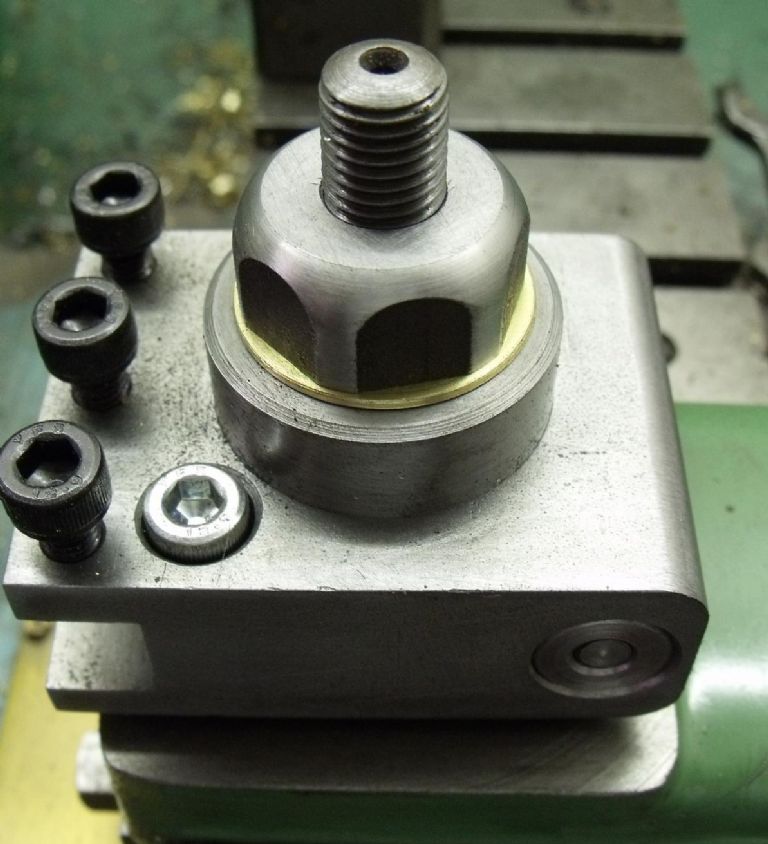

A simple easy change design is to use a rotating centre stud cross drilled for a tommy bar arranged to engage in a castellated hollow nut on the toolpost. Once the nut is set a fraction of a turn releases the tommy bar so it can be pulled out to change the block. Needs an indexing system underneath to hold rotation alignment. Shimming HSS tools to height is much less of a pain as it can be done off the machine by direct measurement. I'd use two slot blocks arranged to index at 90° and parallel to the bed. One day I might make it just to see if it works. Having plenty of Dicksons I don't need it.

Clive

Clive Foster.