Part 3 – Peristaltic Pumps and others…

Since the problem lies with the control of coolant liquid feed, I felt a Peristaltic pump might work better.

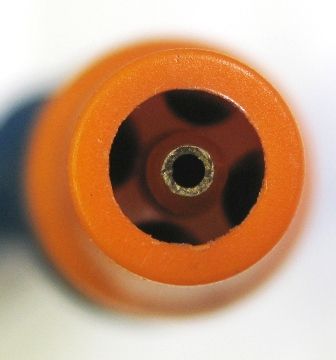

An HDPE housing with 4 wide ball bearings attached to a crude holder were made.

This worked very well, but the hose is a problem. The one used is far to stiff and thick walled – silicon, readily available to me in various sizes, does not work with cutting oils, tygon is only available to me in thicker tubing, unsuitable for this application. It is difficult to get Butyl, Viton, etc tubing in Namibia, and purchasing abroad is equally difficult as I would like a half dozen varieties to try…Not sure what to do here…

Then I lost my head and decide to try other pumps – a petrol fuel injection pump, for example.

I was able to get very low flow rates at about 2 volts, and a 10cm long stream at 5 volts. At low flow rates, since this was not a positive displacement pump, the flow would still vary hugely with pump or nozzle orientation.

Another useless exercise…

I tried a windscreen washer pump as well – I did expect this to be the worst since is has very poor flow performance, etc. A further issue is that the fuel flows back so freely through it that it syphons back to the holding tank, and the when you turn on coolant again, it takes forever for the coolant to exit the nozzle at the low flow rates

I even made up a non-return valve to prevent the syphon process – worked fine, but still has all the same problems of flow rate changing with nozzle height, ie, pump head affects the flow impossibly.

I still think the peristaltic pump is the answer, but the tubing…

And NO, I do not want to use a coolant sodden paint-brush, or a squirty bottle, or whatever..and I hate flooding-

I like the idea of a sort of no-fog lubricator, with variable compressed air to blow chips out of the way, but all the commercial systems I have played with have warts – flow rate is not deterministic at all, and I do not want to lose concentration of a fine machining job, trying to adjust the coolant flow because suddenly it is obscuring the job, or there is no coolant at a critical instant, etc.

Joe

PS – No idea where to post these sorts of long and verbose posts of mine – none of the forum headings seem to leave room to manoeuvre for this? If this is to long or not suitable – let me know! Just thought some folk might be prevented from >>

Edited By Joseph Noci 1 on 07/06/2017 22:44:25

HOWARDT.