I thought i would start a new thread.

Maybe it has been done before , but i have not come across one. If there is one then maybe Jason or Neil would want to move this over.

So 2 things really . 1 My son has bought his 1st house. It is in the same street as we live in. He is like me a bit car mad. So in my workshop i have 2 tool cabinets. Pretty good quality. But they are not mine. I lost all my stuff in a /?';., divorce.

His new to him house has a double garage & a pit. So he will be needing his cabinets back at some point.

2: I am going to need more storage cabinets,, drawers etc.

I started looking around for more storage cabinets & ended up on the usual ebay. I found 2 things that caught my eye. There was 2 workbenches with under drawers unit & a wall cupboard. Made by Clarke machine mart. Pictures below. I do not need more workbench tops , but reckoned that they could be removed. Anyway the cupboard is £115 new. The workbenches are £330 each. I bid at 10 seconds from the end & won them for a grand total of £137 , Pick up was 50 miles away , but i have a Vivaro van so no problem.

On to the 2nd item. It was a 9 drawer 1100mm wide drawer unit. I won this for £51.01. Don't ask why. I just bid £61.00 & thats what i got them for. They are heavy industrial drawers with 6 caged roller bearing on a carrier that holds each drawer.

The Clarke drawers were terrible & the runners were about 15mm deep & hung to the unit on 2 little tags that just hooked onto the chassis.

Moving on i took all the drawer runners off & have fitted heavy duty 50kg sliders. The 9 drawer cabinet was in a bit of a state & was lifted into my van with a fork truck. Heavy is an understatement.

I can only carry 1 drawer at a time.

They are now all in position & i just have to finish painting the drawer fronts & it is all done.

So i now have all the storage i will hopefully ever need & my Son will have a workbench & 3.4 mtrs of worktop. + 1 of his cabinets back. I am keeping 1.

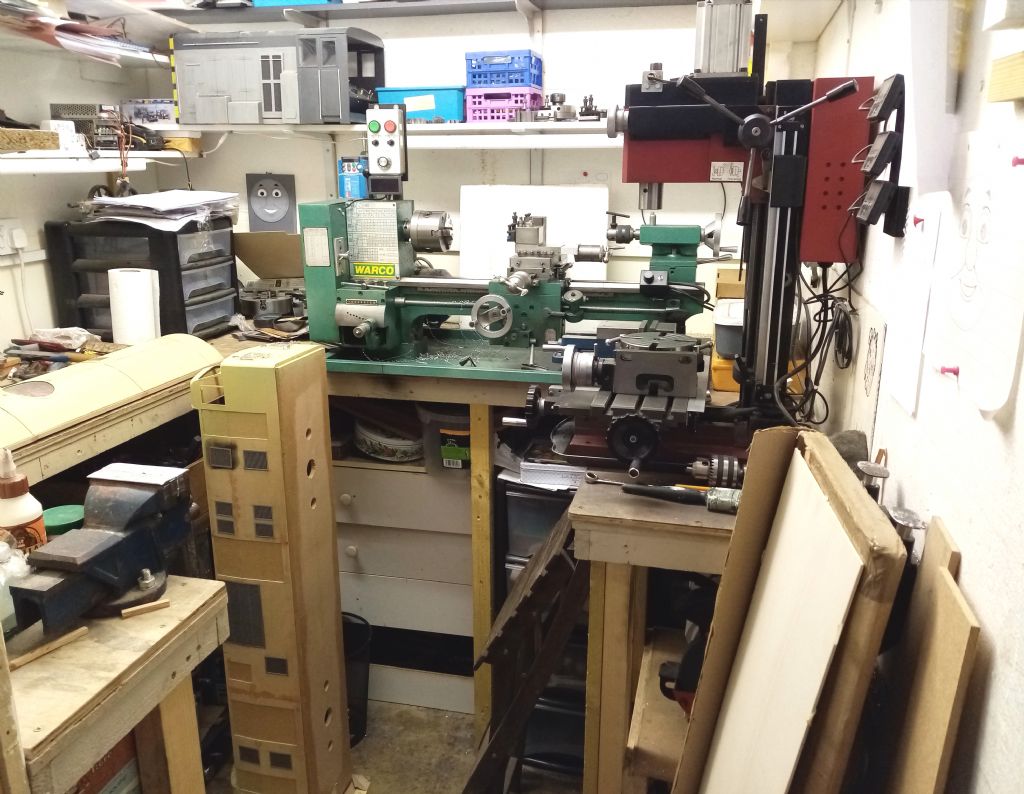

Pictures. Post your workshop pics here. We hear of your machines but little of your workspace. Large or small. Share.

Steve.

Steviegtr.

Steviegtr.