Hi everyone,

Yes it is 0.002 mm resolution .

I plan on using it as a TDC finder on my model engines so i will have to make a custom mount .

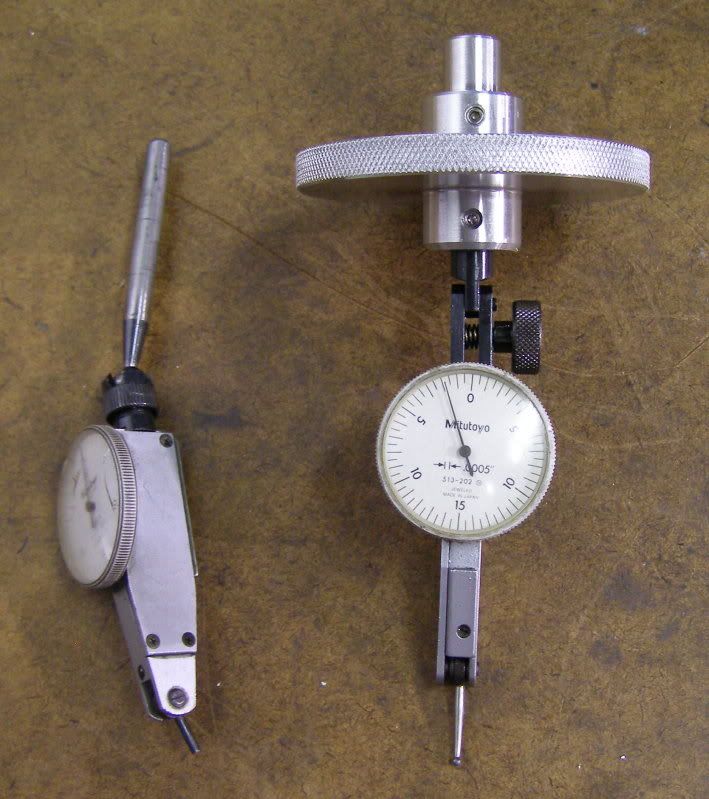

Ian that old #196 starret back plunge are useful for tramming mill tables as you can always see the dial face , they use a spiral staff to give movement to the needle and i have no idea how they get a spiral accurate enough to give a 0.001" resolution but I they do !

Off the top of my head i counted 13 indicators in my kit , a couple of 2" travel units 1 cheapie and 1 mitutoyo , 4 Dti in starrett , mx ( chinese ), tesa and spi (rebadged compac). Dial gauges range from cheap units i keep on cheap stands for general workshop use as I don't care they get broken through to starrett , compac and now a mercer.

For my mini lathe and little taig i use a Starrett last word as it is nice and small which is on a little tiny cheap mag stand that after a bit of a tuneup works ok .

I think that my collecting of indicators gauges is rapidly becoming a bigger sickness than my collecting of machinery ! Worst of all when i ran out of room i had to stop buying lathes and mills but indicators are small so i can always find somewhere to hide another one !

I'm thinking of getting the mercer serviced by someone who does this for a living as my big sauusage fingers are not suited to playing with little screws and gears !

Hopper ,

There are a few recommendations i have seen -petrol is one another was shellite or white spirit , apparently they leave a minute film behind which is all that is needed and the toolmaker i used to work for said the same as any oil traps dust and eventually dries up .

I have also been told to use watch oil on the bearings and gears but my tesa dti says not to oil anything at all so iguess each manufacturer is different .

I have been hunting around for a noga stand but to buy new here is so damned expensive !

Once again thank you all for you replies and ideas !

Ian

Edited By XD 351 on 10/08/2016 21:14:06

I.M. OUTAHERE.

All makes me wonder if the best option when starting out is to just buy a brand new decent quality one. Might work out cheaper in the end. Just make sure it's the right one.

All makes me wonder if the best option when starting out is to just buy a brand new decent quality one. Might work out cheaper in the end. Just make sure it's the right one.