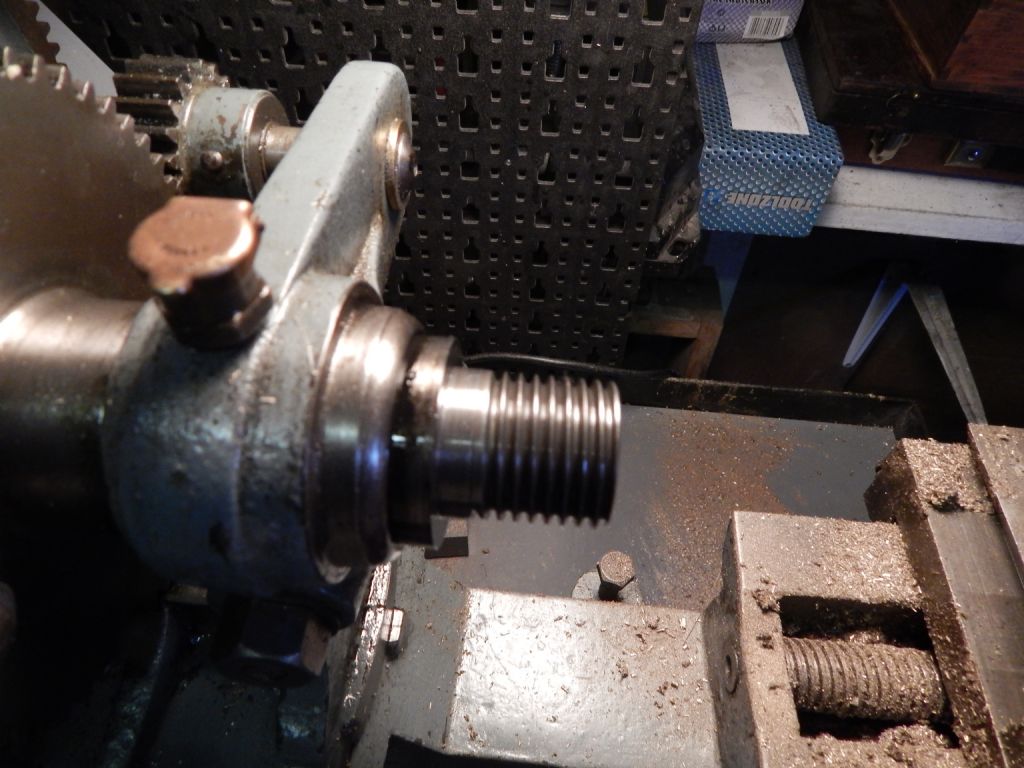

Now that the cause of the problem seems to have been found, DO take the advice to buy Thread Gauges. Since you are likely to come across variety of thread forms, ( Whit, Unified and Metric) and pitches DO buy all three.

A steel rule with Imperial and Metric graduations is a good rough starting point ( But 10,12,18 or 28 tpi may not match the graduations on the rule – hence the need for gauges.

Whit form will cover 55 degree thread forms, such as BSW, BSF BSP (Gas), B S Brass, and Model Engineer 32 and 40 tpi. Unified will cover 60 degree Unified and Cycle thread form, but NOT Metric.

Metric threads are also 60 degree, but the pitches will be Metric not Imperial.

If you are likely to get involved in older electrical items, you might find BA useful, since the thread form is 47.5 degrees, but the diameters and pitches are metric, each changing by a factor of 0.9.

You are less likely to get involved with Acme or Buttress threads, so wait until you need gauges for those.

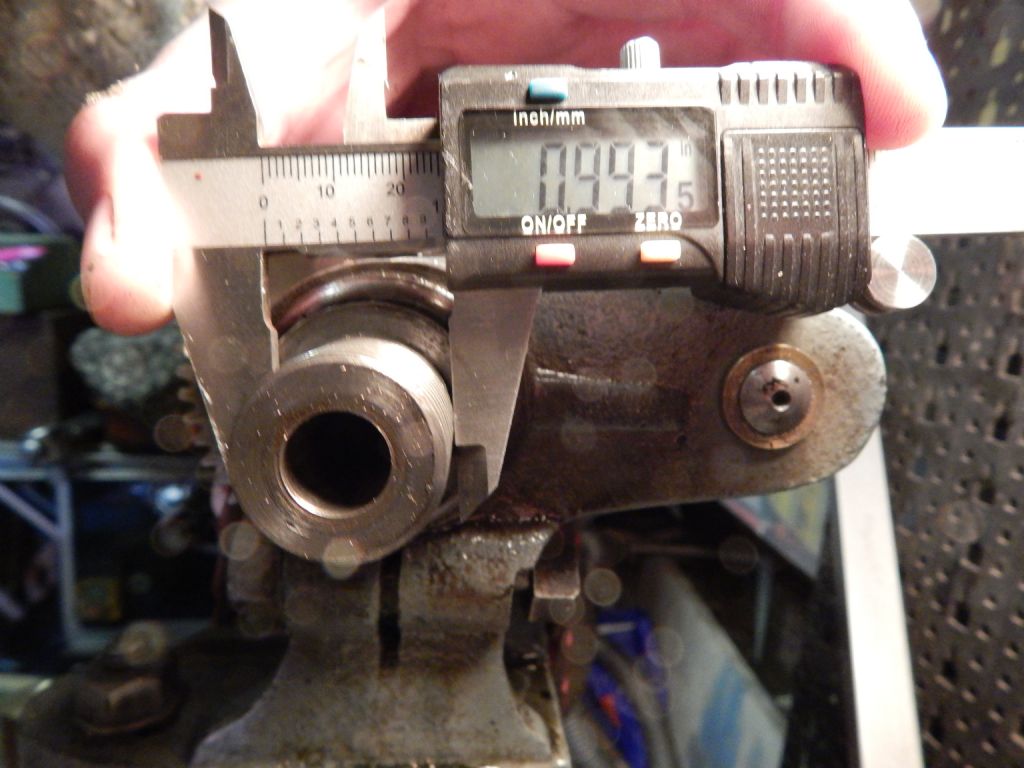

Once you know exactly what a thread is, form, pitch (or tpi) and diameter; you can obtain or make a correctly mating part.

If you don't know, you are working blindfold, and will waste at least a lot of time, if not money and material.

Howard

Ian S C.

Live and learn ML7 is not Drummond

Live and learn ML7 is not Drummond