Nathan,

I am a little more than normally confused !

You say X axis parallel to the drill. To me, vertical travel means Z axis, with X axis being Left/Right, and Y Front/Back.

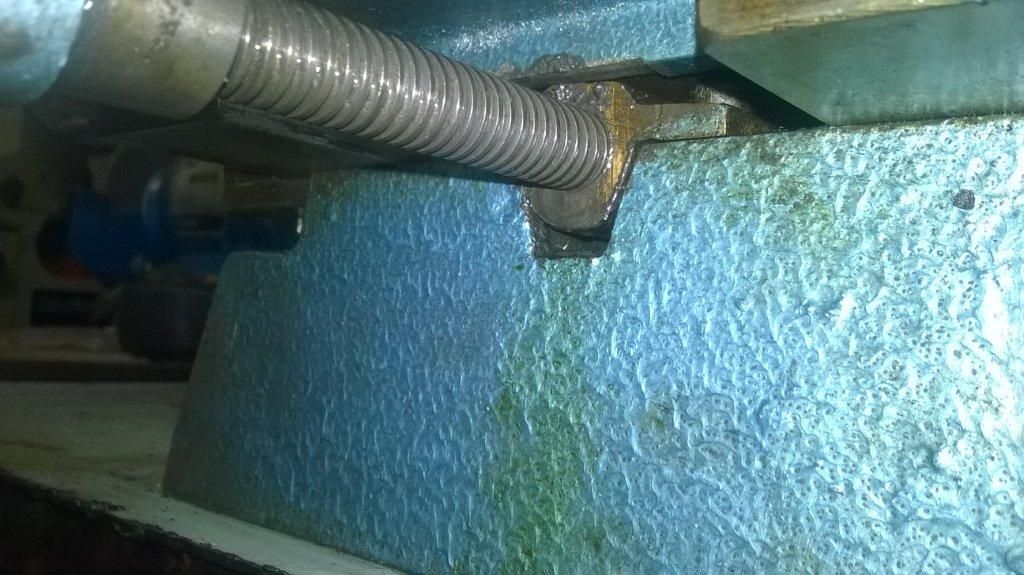

The pictures look as if you are dealing with the vertical feed for the table (Z axis in my speak).

Bevel gearing will introduce additional backlash to that already present in the Leadscrew / Nut.

Also, the gears each need to be fixed firmly to their respective shaft, not only to reduce overall backlash, but to prevent damage to both shaft and gear. (End float on the driving gear shaft will also increase backlash)

From what others have already said, the carrier for the nut can become loose, so that will increase backlash even more, and cause wear of the holes and securing hardware.

Once correctly positioned, would it be possible to dowel / rollpin through the frame and into the nut carrier?

If you are desperate to eliminate backlash, if there is enough material in the nut, it could be partially slit, and then one end tapped for a screw to force the two sections apart. This will reduce backlash; although not as elegant a solution as having the ability have a second nut rotatable relative to the main one, to act as sort of locknut

In my experience, it is not too uncommon to have about 0.020" backlash in a drive. You need to be aware of, and allow for it, if reversing the direction of travel. My method is to lock the travel, reverse to take up the backlash, set the dial to Zero, and then unlock before traversing.

Howard

Danny Hegh.

7" dia hand wheel on the side.

7" dia hand wheel on the side.