I have had several requests for information on the above dial following my posting of the above photograph on the Forum post about Blacking solutions recently.

I thought a few words about the modification might not go amiss. I took delivery of the Maximat in 1986. The original handwheel dial was calibrated to read 19 mm per rev. I soon got used to working with this odd number but had placed a replacement on the too do list.

Thirty years on it was still there on the list, and following a day when I had made 3 components wrong due to my metal arithmetic not being as good as it used to be I decided it was time for the replacement.

First thoughts were to go for a dial reading 25 mm per rev, as an imperial version could be done with 1" per rev. While I did manage such a design the dial was larger than the handwheel and the whole thing looked hideous.

I finally settled on 20 mm per rev, although the dial was slightly larger than the original. This would be easier I thought as the gears only have to have multiples of 19 and 20 for it to be an exact conversion. That was until I actually checked the travel per revolution of the handwheel which turned out to be under 19 mm. Not a lot under, but as I was going to use a gear train I could at least get it right or nearer.

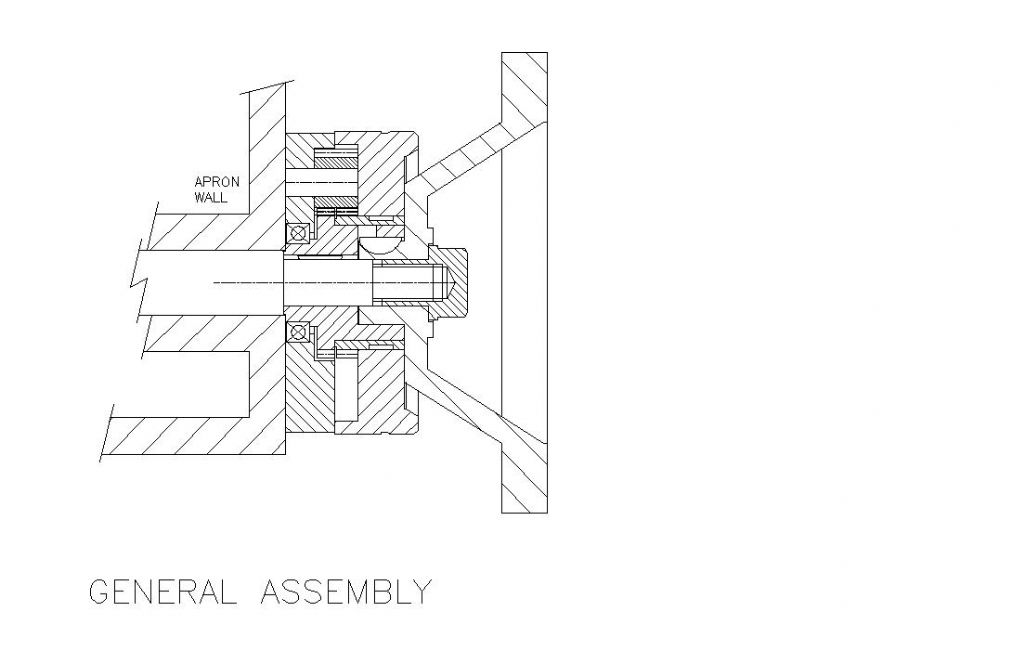

The perfect ratio came out at a 38 tooth gear driving a 39 in a single reduction. This presents a problem as for the two gears to be co-axial then one gear has to have the PCD enlarged or the other needs to have the PCD reduced.

To produce these gears by standard B&S gear cutters is not on. In Industry it is not such a problem if there is access to a gear hobber. The Home Machinist can however still make a single point cutter that will come very close to the required form. It just needs an understanding of how to draw gear tooth profiles. This then was the approach I took and the results are shown below.

To help eliminate backlash in the system a Delrin Idler gear was used which was cut with zero backlash. Any backlash that is present is removed by adjusting the dial in the direction of travel. The assembled dial has lived up to my expectations and I am glad to report there has been no scrappers since.

Regards

Gray,

Graham Meek.