Thanks to all for every cogent and germane reply to my novice question.

Everyone is so generous with their time and information!

It seems like the EMCO yahoo group has now taking place at groups.io, indeed. Furthermore, the group is called EMCOV10lathe. The group is not limited to the V10 machines, but rather is for all EMCO machines. That is my initial take, but don't take is as any gospel, please.

The EMCOMACHINETOOLS.CO.UK website refers to having operational manuals, oh boy  , but there are no links to them, as opposed to the active links for parts manuals and EMCO brochures. Boohoo

, but there are no links to them, as opposed to the active links for parts manuals and EMCO brochures. Boohoo

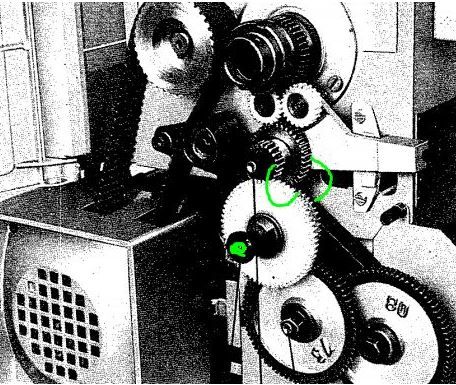

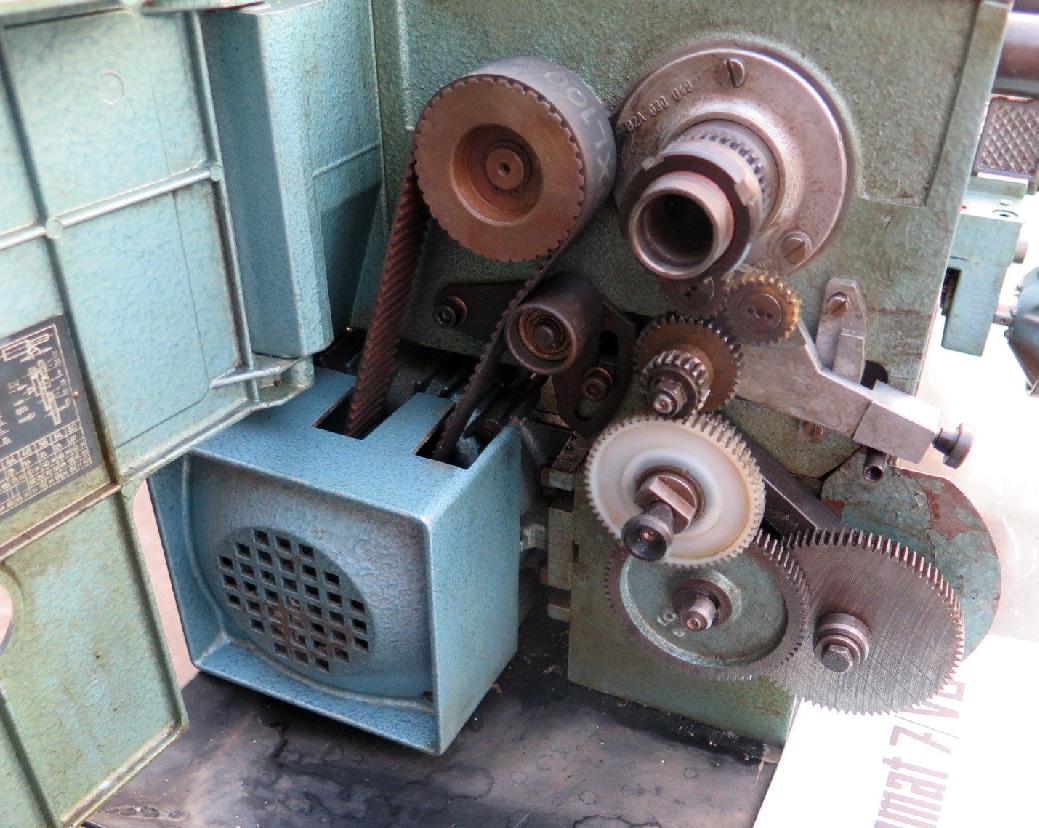

Han ("Versaboss" has my partial answer to my question: EMCO used two different size tumble reverse gears, thus when both are interacting in the changegear gear train (with the lever in the up position), the leadscrew speed is indeed faster. When in the down position, only the smaller gear is in the train, and the leadscrew is slower.

has my partial answer to my question: EMCO used two different size tumble reverse gears, thus when both are interacting in the changegear gear train (with the lever in the up position), the leadscrew speed is indeed faster. When in the down position, only the smaller gear is in the train, and the leadscrew is slower.

So as Hans mentions, this gives the lathe more capability (rather ingenious I think) because when simply using the change gears to drive the power feed, the operator has at his or her disposal, two feed speeds, as Hans refers to them as "coarse" and "fine." This being then coupled with the change in direction (that's why it's called "Tumble REVERSE, afterall), and the number of screw pitches that can be cut with this "vocational" machine is doubled! The practicality of that is not understood by me, but initially, I think that the pitches generated with the lever in the "alternative" position would be of no value, unless they coincidentally happen to be Module or Diametral!!

But this doesn't answer my question: Is the tumble reverse lever supposed to be in the up or down ("coarse" or "fine" position, when cutting screws per the screwpitch diagram of the lathe?

position, when cutting screws per the screwpitch diagram of the lathe?

If I had the manual (which emcomachinetoos.co.uk apparently doesn't carry, it might answer my question.

So without that, I'll just have to knuckle under and get some experience. I'll cut some test screw pitches with the tumble reverse in the up position, and then the down position, and simply count the threads!

Thanks again to all, you gentlemen are valued and appreciated! You gentlemen are kind.

Avery

Avery Neaman.

has my partial answer to my question: EMCO used two different size tumble reverse gears, thus when both are interacting in the changegear gear train (with the lever in the up position), the leadscrew speed is indeed faster. When in the down position, only the smaller gear is in the train, and the leadscrew is slower.

has my partial answer to my question: EMCO used two different size tumble reverse gears, thus when both are interacting in the changegear gear train (with the lever in the up position), the leadscrew speed is indeed faster. When in the down position, only the smaller gear is in the train, and the leadscrew is slower.