Thank you for the guidance and information so far.

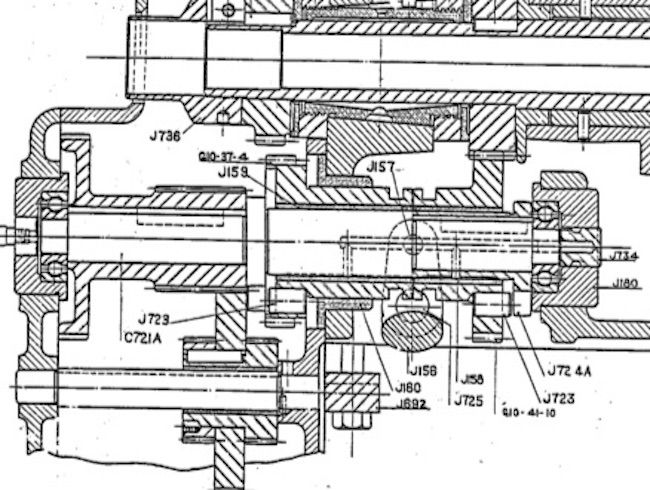

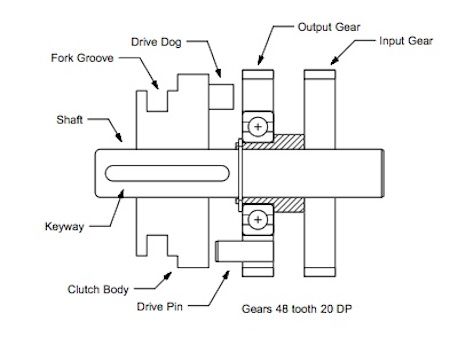

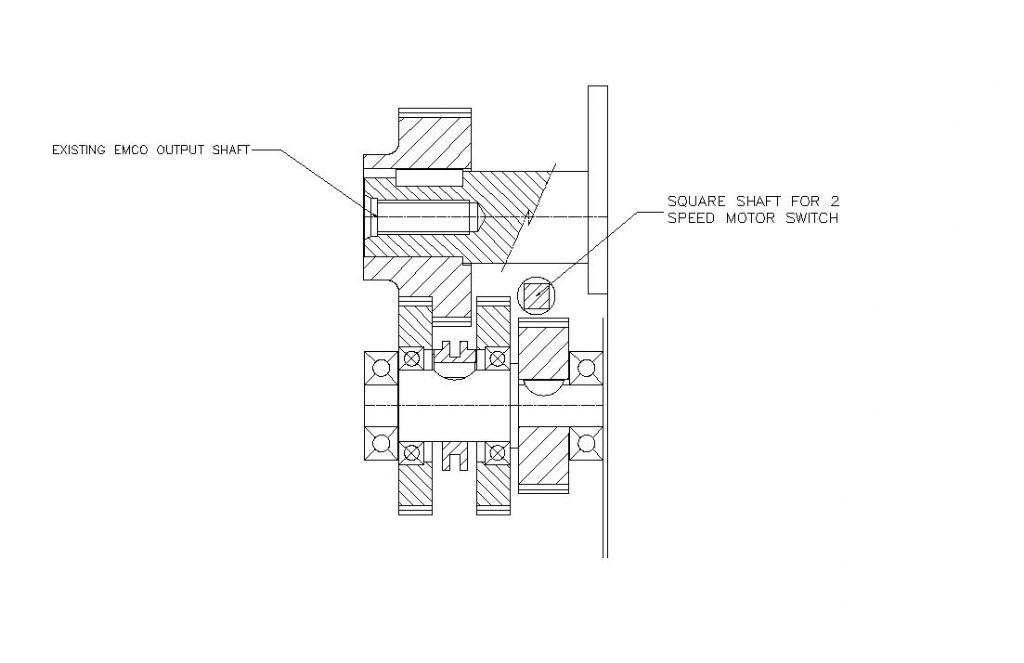

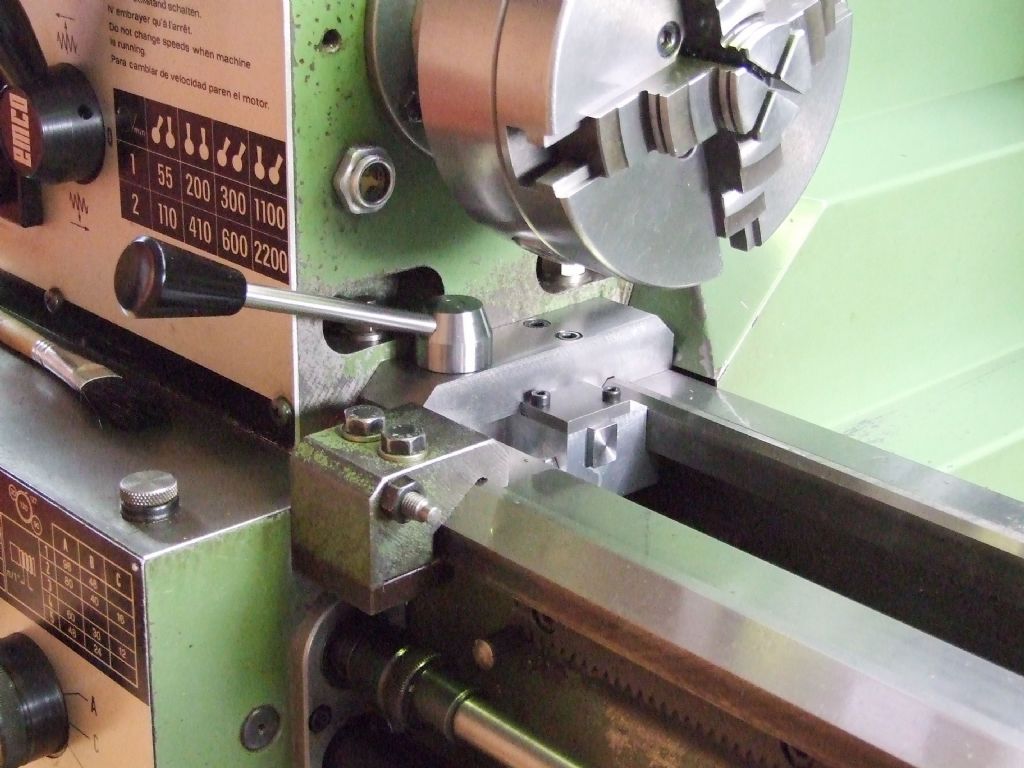

I have read the Jim Schroeder article where he adapted the clutch to fit his Grizzly G0602 lathe. The G0602 lathe is very similar to my Craftex CX700 and I believe they are both built using the same castings/platform. I believe the Schroeder adaptation plan would be mostly correct for my lathe but……

There are some differences between the lathes that would need to be addressed to make the Schroeder adaptation fit my lathe, but I do not have the mechanical mental ability and know how to grasp exactly how and what those changes would look like.

My lathe came equipped from the factory with a reverse tumbler mechanism. Does this get superseded/eliminated with the clutch?

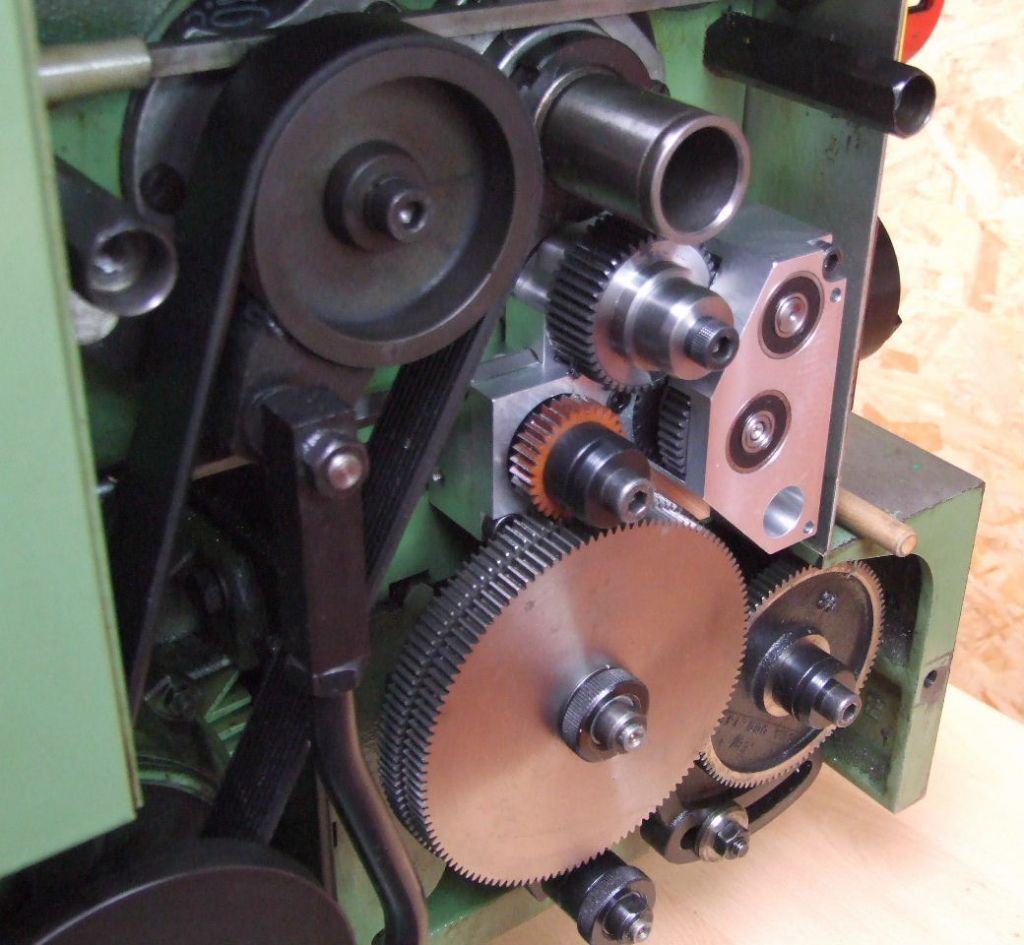

My lathe uses module 1 gears as opposed to module 1.5 gears used in the Grizzly G0602. How and what do I need to figure out how to make changes for that difference?

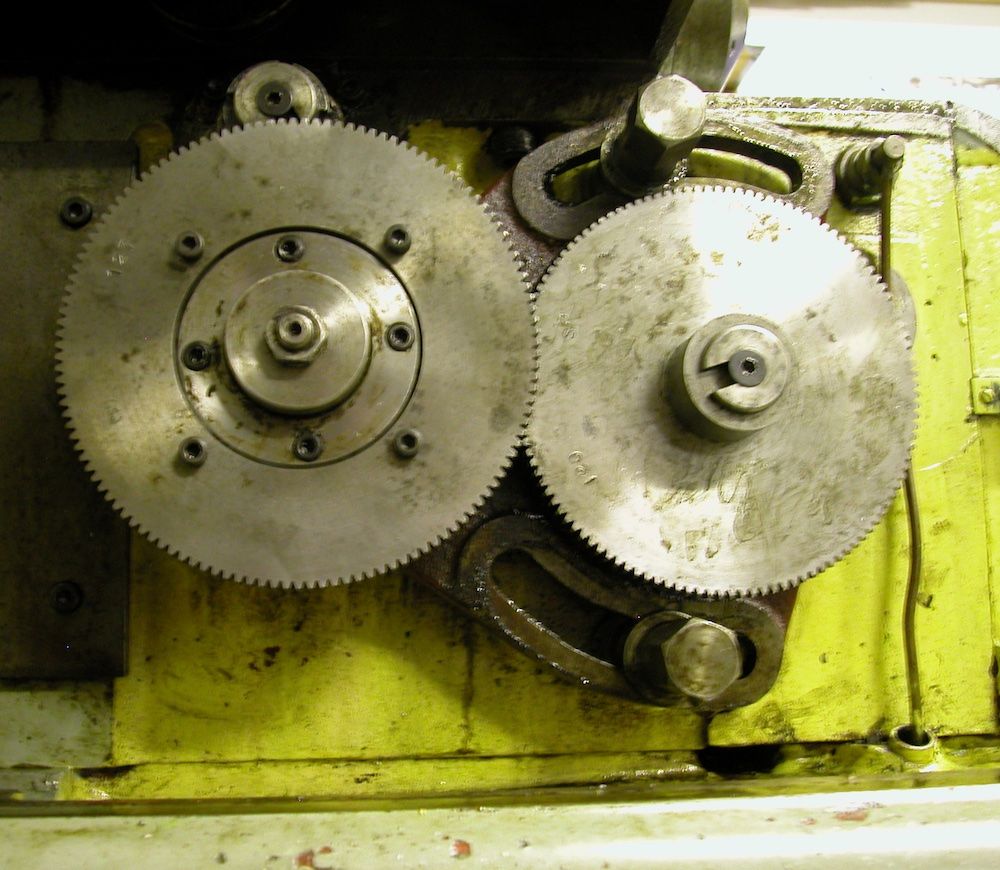

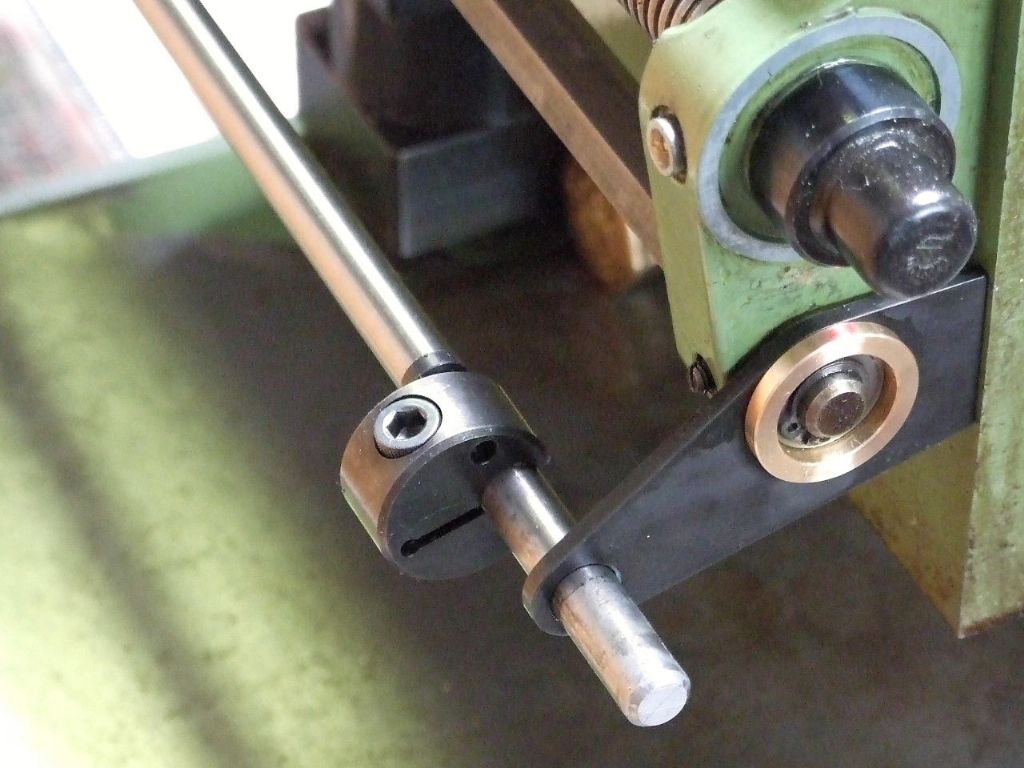

Here are a couple of pictures of my lathes gear train.

Edited By Don Pittman on 04/04/2021 23:23:24

Edited By JasonB on 05/04/2021 07:03:01

Graham Meek.