Posted by Roger B on 02/11/2022 09:51:25:

…. He also proposed that combustion should be a constant pressure, although in reality I don’t think this was ever truly achieved, and the maximum expansion of the gas during the power stroke…

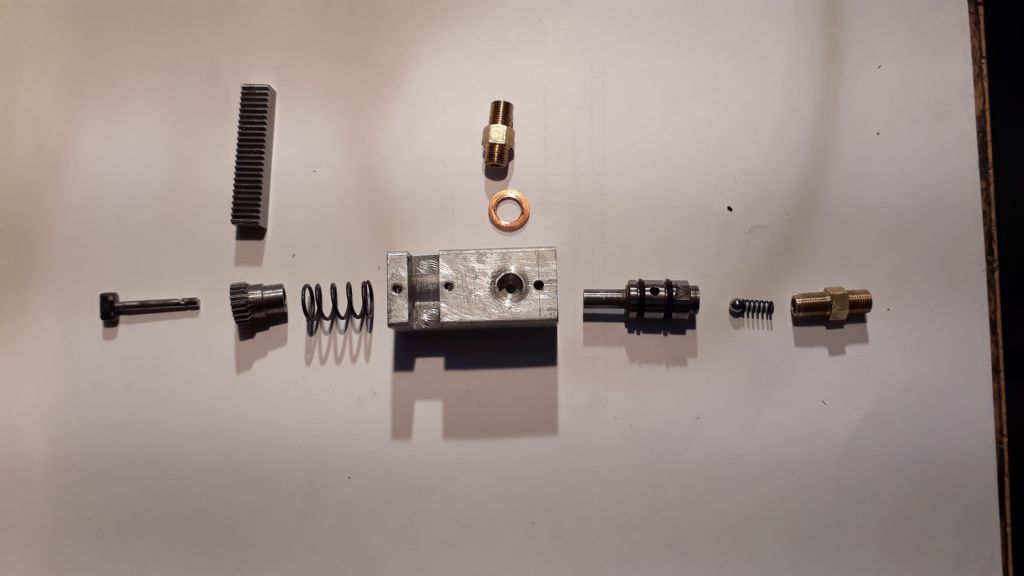

The helix plunger is made from a piece of a hardened and lapped pin gauge. I started out using hardened and lapped silver steel but after some problems with a trilobed piece I moved to the pin gauge. The helix is ground using a Proxxon hand tool in my Hobbymat lathe with the change gears set for 4mm pitch. The other end of the helix is annealed and threaded M2 for the tappet.

I doff my cap to you, sir. I've always thought it would be pretty tricky making a full-size pump element, let alone 2mm diameter (and with a Proxxon!).

I think part of the problem with constant pressure combustion was that it couldn't be hurried, and so was only (sort of) feasible in very large, slow running engines. Herr Diesel, aiming to use the Carnot cycle, originally intended that his engine should use isothermal compression (realised by injecting water into the cylinder), and isothermal combustion. It would have no cooling system, in fact the cylinder would be insulated. And it would also burn coal dust.

Unfortunately theory didn't translate to a workable engine (partly due to the extreme pressures that would be necessary), so Diesel omitted the isothermal compression, and after much experimentation and discussion with his team, ended up with a practicable cycle that used isobaric combustion. Modern, high speed engines seem to have a combination of constant volume and constant pressure phases.

Andy Stopford.