This all seems a little murky!

I'm pretty sure that you can't buy an ELCB any more. Someone is bound to prove me wrong, but broadly I would declare the ELCB technology obsolete. They work differently from RCDs although they do a similar job. An ELCB actually measures earth current. In situations like "TT" supplies where an actual ground spike is the only method of grounding, the ground impedance can vary wildly. If the ground potential does vary, it can render the ELCB useless, and no one will know.

RCD technology compares supply and return current. It calculates the difference and infers the earth current, even if that current is not passing through the earth conductor. It requires no earth connection and helps to make "TT" supplies much safer.

All modern switch mode supplies (of which inverters are a kind) usually require some kind of EMC filter to allow then to pass conducted emissions tests and gain CE and other approvals.

EMC filters work by providing a high frequency path from the live and neutral conductor down to ground. Generally the impedance of an EMC filter from LN to E is fairly high. Indeed there is normally some leakage even in a simple electrical appliance with a line transformer. Typically the coupling is capacitive from the primary into the frame of the of the transformer.

It from the perspective of the RCD these leakages can accrue. If you have a single RCD on a whole premises, then it is possible that all of the leakages can accrue to the point where nuisance tripping occurs.

In general, nuisance tripping of RCD's is much less pronounced than it is for the old, less safe, ELCB technology.

Most appliances leak much less than their allowable class limit, but it is a particular problem with motor inverters, because we all want nice (sonically) quiet motor drives. In order that the switching noise cannot be heard in the windings of the motors we all wind up the switching frequency so that it is outside of the audible range.

The downside to this is that it pushes electrical energy out into the network at frequencies which are quite tightly controlled. The regulatory authorities consequently demand EMC filters to prevent this from happening.

The EMC filters for motor inverters are usually quite big, because AC induction motors are a heavy load. The electrical noise is powerful and at high frequency. These signals can interfere more easily with radio systems. Appropriate EMC filters can leak quite a lot.

Most loads are not big motors.

In your workshop, you probably only need one inverter running at a time. If they have a proper isolator, then they probably don't all need to be connected at the same time. If they are not all connected at the same time, then their EMC filters cannot accrue leakage.

Decent inverters usually have selectable EMC filters. I bought a Schneider, and it says that if you disable the EMC filter then you should run it at a low switching frequency, to remain compliant. Sure you can hear the motor hum but so what. Mine actually has a dynamic mode. If the load increases, the switching frequency reduces. This maintains compliance, and is quiet most of the time. I actually quite like it. I get feedback about how I am loading the motor, by the sound it makes.

I commissioned a medical robot a while back which had several powerful (>1HP) axes, all of which had their own inverter. Obviously the axes all had to be on at the same time to achieve co-ordinated motion. Being a medical robot it had to be compliant. The answer was to provide external EMC filters. A single combined filter does not have to have the same leakage as the sum of each filter together.

Conducted emissions are only high when the motor is loaded. It is not likely that all axes will be maximally loaded at the same time. Even if they are, it is only a temporary situation.

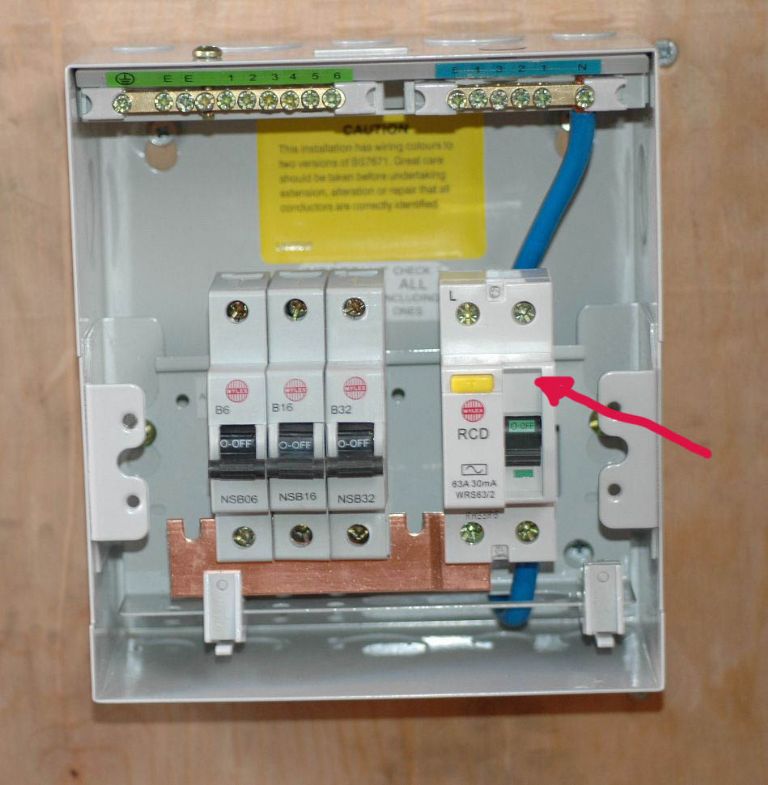

Increasingly electrical switchgear manufacturers are promoting RCBO's. These provide discrete RCDs combined with traditional thermal-magnetic breakers. Instead of having a single RCD each "fuse" has its own. By using these RCBO devices, accrual of leakage can be managed, and nuisance tripping reduced.

In high load situations perhaps greater than 50A it might be the case that it is hard to find an RCD capable of the job. It should always be remembered that inverter systems can often be isolating.

The isolating nature prevents the controlled AC voltage generated from being directly hazardous. Clearly, if a circuit with no RCD protection is used and used in a fixed wiring scenario (supply side trunking/conduit) then safety hazards are inherently constrained.

Obviously no RCD with a non-armoured trailing cable has its hazards.

Andy.

Edited By Andy Ash on 21/10/2016 23:09:31

Muzzer.