Hello

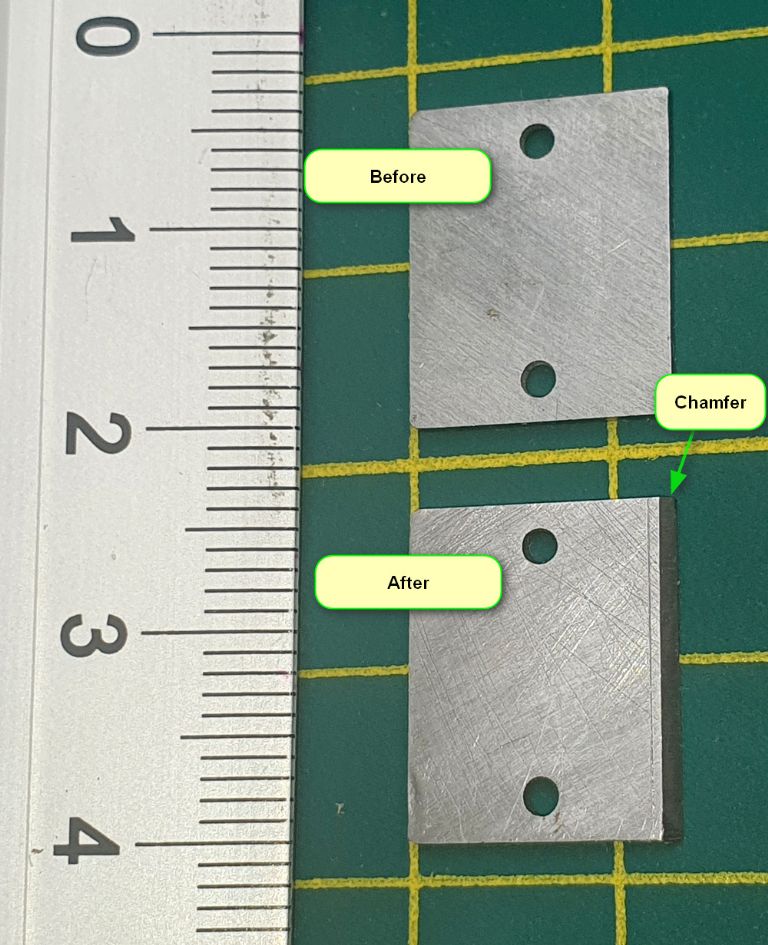

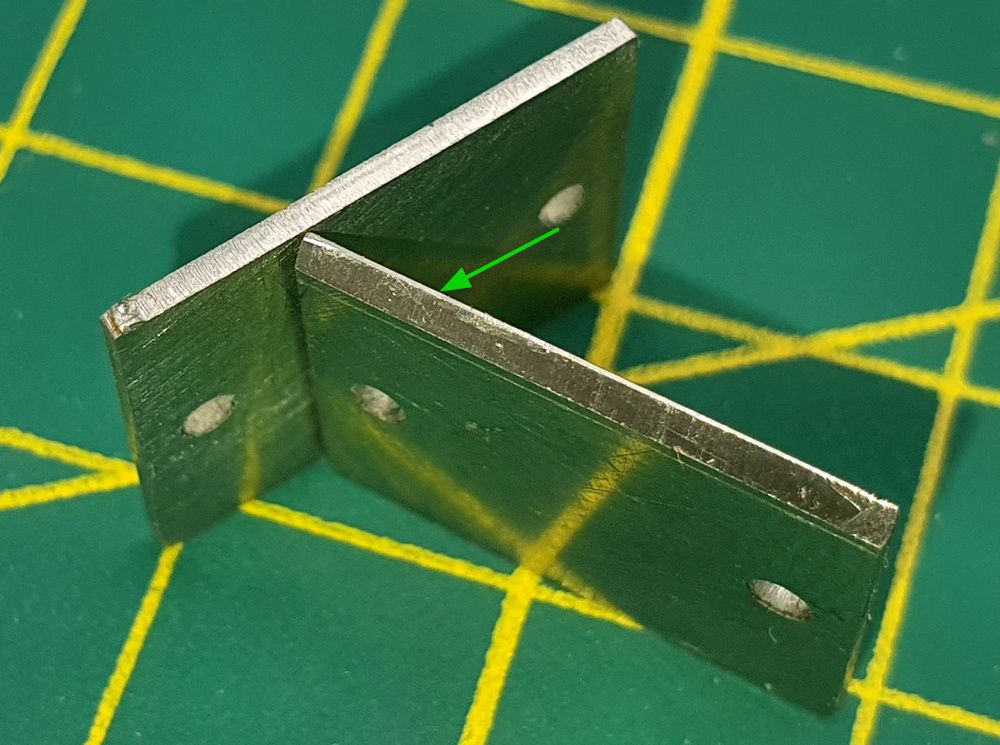

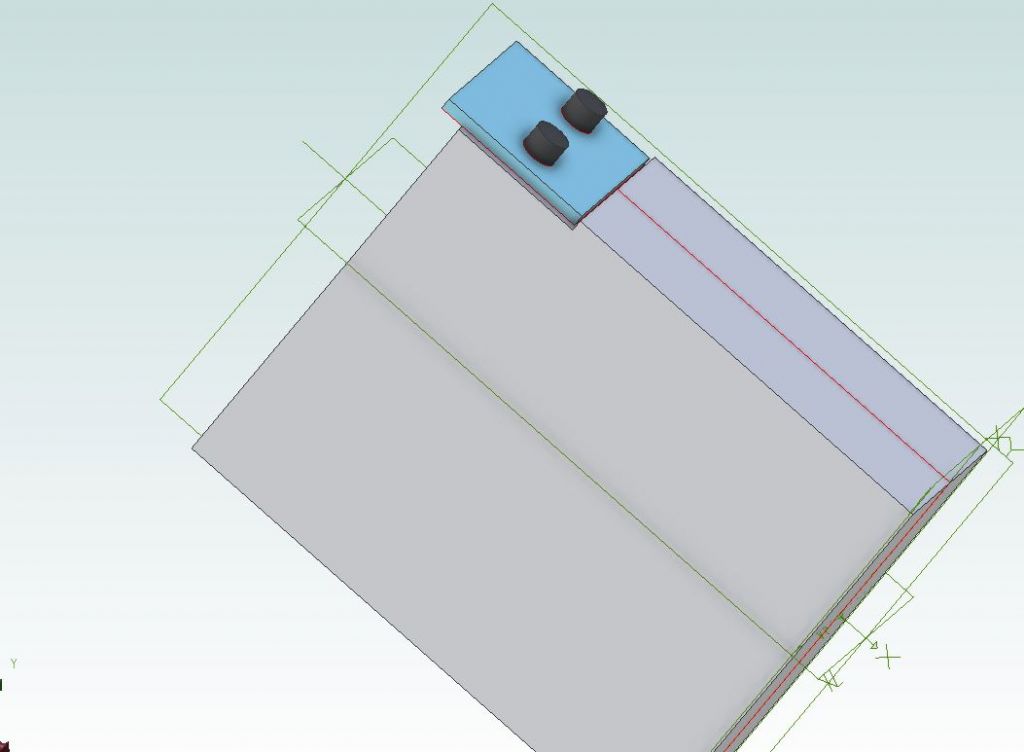

I need to make a 45° chamfer on one edge of each of these small pieces of mild steel – which are 16mm x 8mm x 1mm in size.

FWIW, the steels have been laser cut.

Below are two "before and after" photographs.

Note: I have cut a chamfer on one of the parts by careful filing the steel (by hand) and by then finishing off with a diamond sharpening stone. My problem is that it took me far too long to make just one chamfer and I need to make at least x64 of them!

[NB Please ignore the scratches!]

Problems:

1. I must not change the (8mm) width of the part, so I must not cut too deep in order to leave a small amount of the original face behind

2. The face of the chamfer needs to be as close to 45° as is reasonably possible (i.e. within say 0.5° to 1°

3. I have at least 64 of them to make!

Background

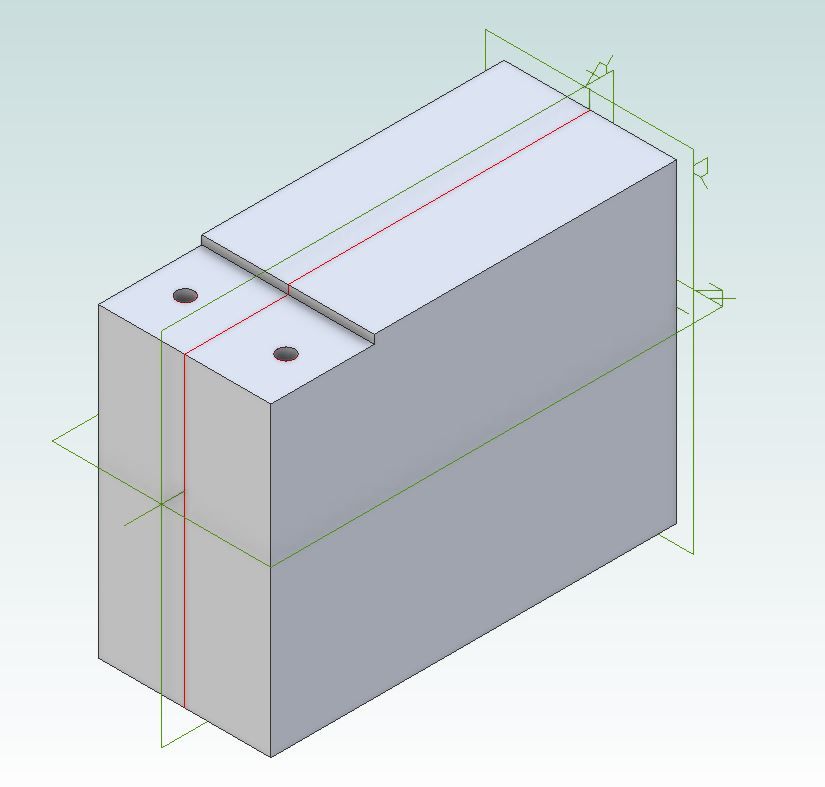

I only have a basic home workshop. As discussed elsewhere I might conceivably by a Proxxon MF70, but I can't afford a more grown-up milling machine (like a Sherline).

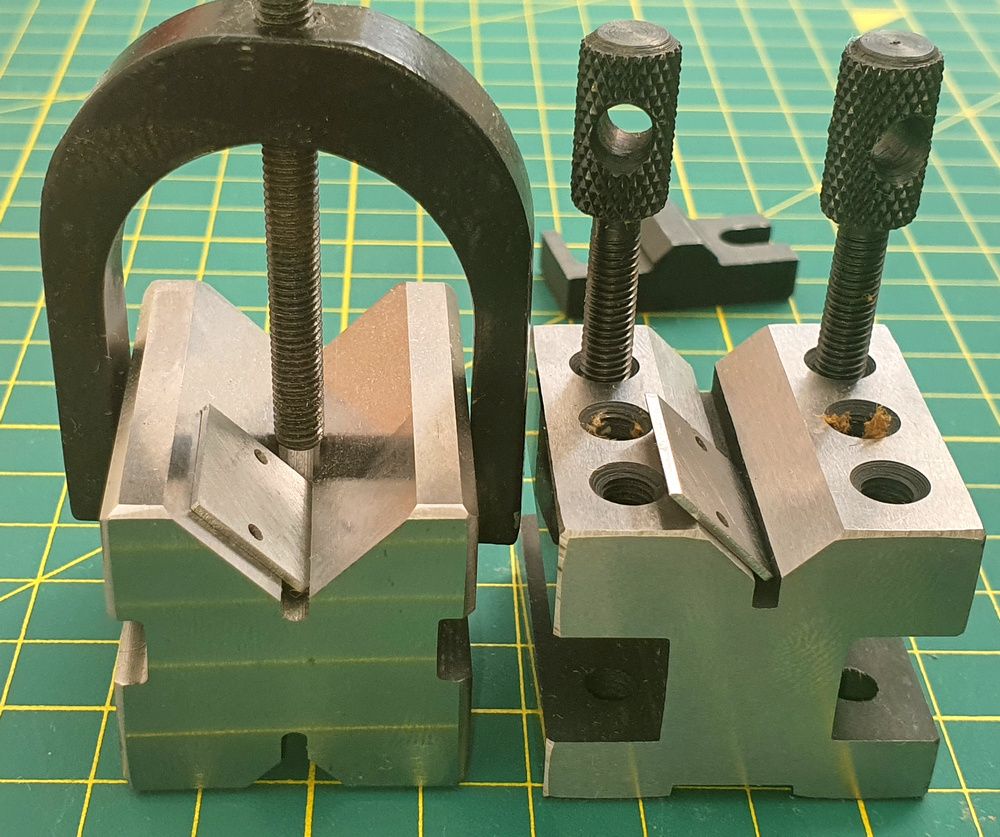

If I bought a milling machine I would need to find a way to cut at 45 degrees. I do own a couple of pairs of V-blocks but I'm not sure how I would use them.

OR should I try to buy avice that can rotate along a horizontal axis?

i.e. This sort of thing??

New toosl budget: £400 max

All suggestions welcome!

J

PS Fwiw, these parts are to be used as magnetic guides. (Long story…)

Edited By John Smith 47 on 03/09/2021 14:43:11

John Smith 47.

My computer is off (typing on phone)

My computer is off (typing on phone)