Posted by Howard Lewis on 11/12/2019 12:14:16:

Folks, are we not making mountains out of molehills?

The theoretical discussions are interesting, but do not do much to help the OP. …

The OP was asking about a pipe between the tender and the locomotive.

The pressure available to promote flow is going to be of the order of a few inches of water, or probably less than 200 mm.

The pressure differential may be increased by the sub atmospheric effects of the injector that it feeds.

But basically, it all comes back to "Will a 1/4" pipe reduce the flow through a 3/8" pipe"?

The simple answer, in these circumstances is a common sense "YES".

As the late Rudi Mischetlager used to say "Common sense is not that common"

Remember the motto of the amateur radio world, KISS, "Keep It Simple Stupid"

Howard

Well, it depends. I prefer Einstein's 'Make everything as simple as possible but not simpler'. He also said 'If you can’t explain it, you don’t understand it well enough.'

Personally I incline to argue there is no such thing as common sense. Here's a few definitions to choose from. Common Sense is:

- What I think you should know without any argument! (Depends on me not being an idiot.)

- A notion shared by many people. (Depends on other people not being idiots.)

- Anything that might be reasonably expected. (Depends on what's meant by 'reasonable'. In English Law, decided by precedence and court cases.)

- Making sound practical decisions with no need for specialised knowledge or understanding. (Depends on the idea that experts know nothing, education is unnecessary, and experience valueless.)

- The basic practical knowledge and judgment needed to survive. (Assumes newborn babes can survive on their own.)

- Just as good as someone else's moral position. (Assumes it's not necessary to understand morality or ethics.)

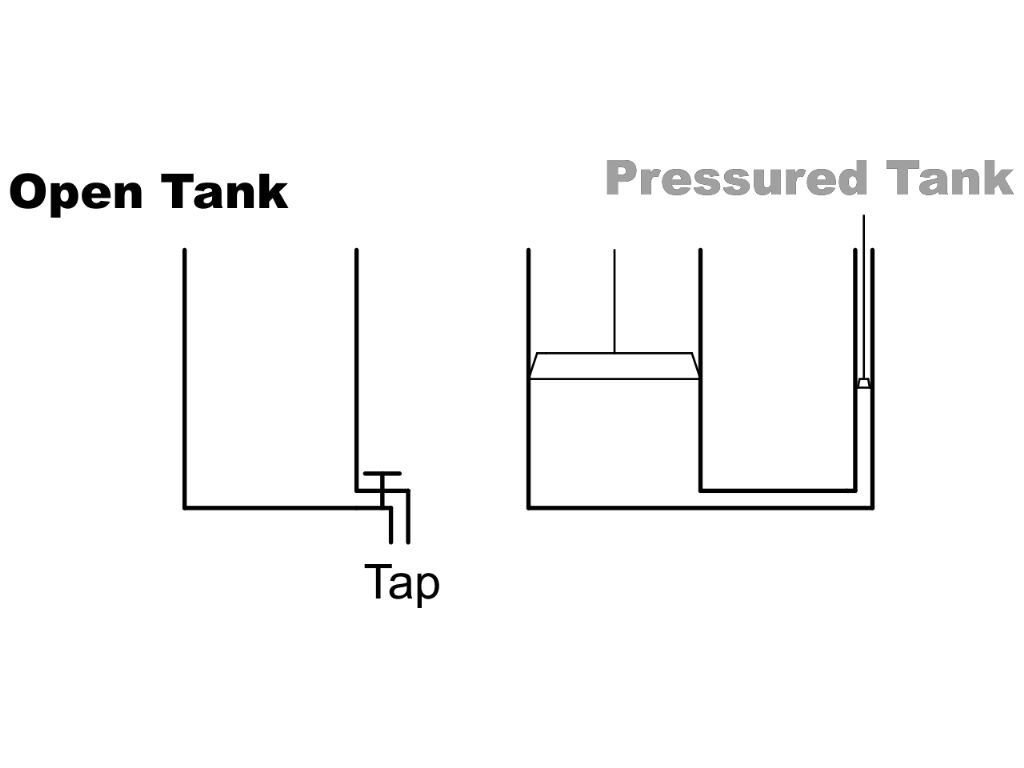

I'm not sure John's question has been answered correctly, though I think Hopper and Robert both correctly identify the main consideration, which is the difference between a tender that's just a tank, and one containing a pump. One assumption is the tender gravity feeds water to an injector, equally valid is a tender containing a force pump for directly injecting high-pressure water into the boiler. Maybe both are wrong, could be the tender is used to fill a tea-urn on the back.

If John wanted a simple practical answer to the effect of a choke on water flowing under gravity, easy enough to do the experiment. The experiment would also find the actual relationship between choke and output volume, useful for answering a question like 'will the choked pipe enough flow to allow an injector to fill the boiler'? A rather harder question is, 'how much longer will it take to fill a boiler with a force pump if the pipe is constrained?' In the latter case, the smaller pipe may be necessary to manage the high-pressure involved, not just a casual feature.

While practical skills are high value, they are strongly reinforced by effective theory. I'm impressed by Lord Kelvin, (physicist as smart as Newton and Einstein) who is alleged to have said: 'if you can't put numbers on it, it ain't worth sh1t!'

Dave

martin perman 1.