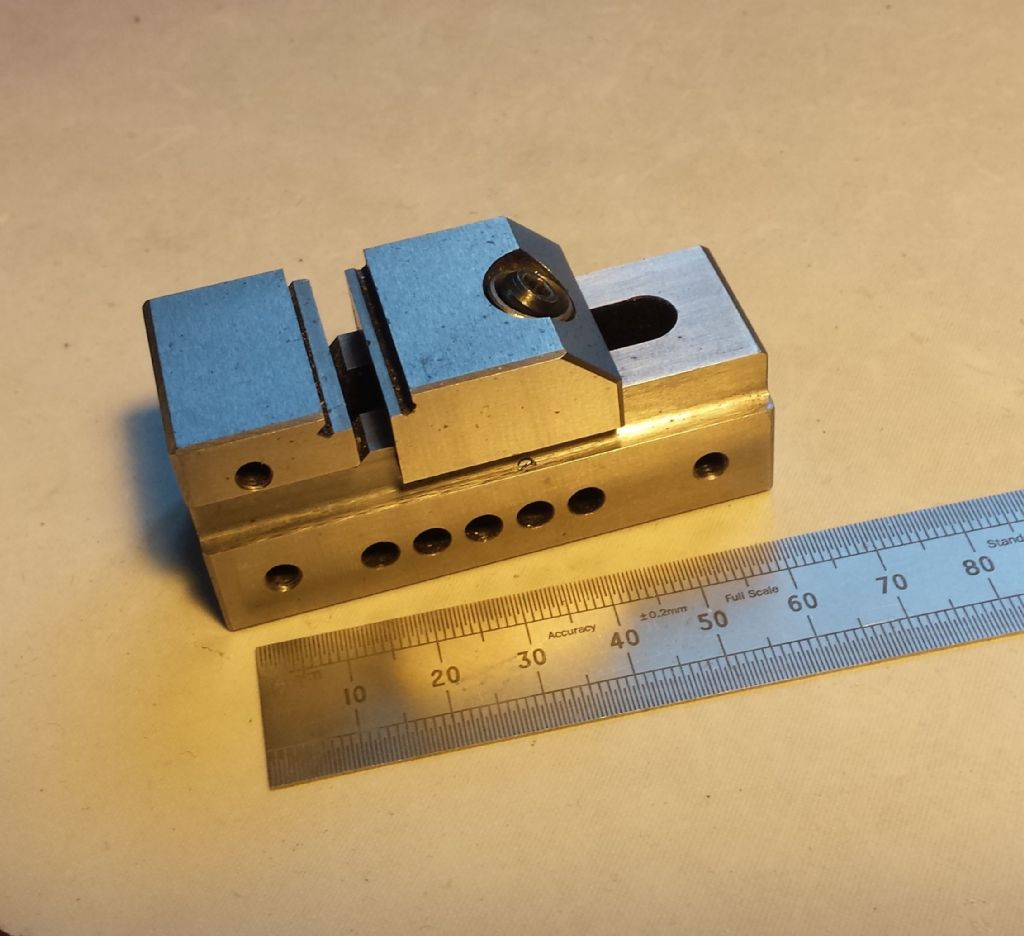

This is the vice I have. I bought it about 5 years ago from a reputable supplier (Chronos I think) and should have returned it immediately. I recall that the main picture on the web page did not show this smallest sized one but I expected it to have the same features as the rest of the range. I dont think the larger ones had the stepped jaws but on this vice they are about a third of the jaw height.

This vice might be precision ground but not to any precise dimensions, nearly every feature is unequal. the grooves on ether side are different heights by 0.1mm, the moving jaw is flush to the body on one side and 0.4mm clear on the other. The slot is offset by over 1mm so I ended up making a new trunnion nut so that the screw had a straight pull.

As regards fixing it to the milling table, there are two diagonal M4 tapped holes on the underside but to me it does not seem good engineering to have to mount the vice on a plate. The M4 tapped holes in the side faces are even less sensible and one of the four needs a tap putting through it (it chews up HT screws) but being hardened I dont want to waste a tap.. Neil's vice does at least have notches at both ends so is straightforward to clamp down.

My main vice is a 68mm 'Precision' vice which is I think intended for metrology purposes rather than milling duty. Whilst it has a certificate of accuracy (parallelism/squareness/hardness etc) typically to about 0.005mm and better, the screw is quite coarse pitch and a very rattly fit, quite out of keeping with the rest of it.

Ian P

Ian P.

Ian P.