I expected to see comments about less flex, parting off and etc. They are interesting tool holders because if set up correctly they can set tools to precise angles reliably. That aspect is about it really – angles. The weakest aspect of any qctp is the base of the holder and they don't really differ from other types of similar size in that respect..

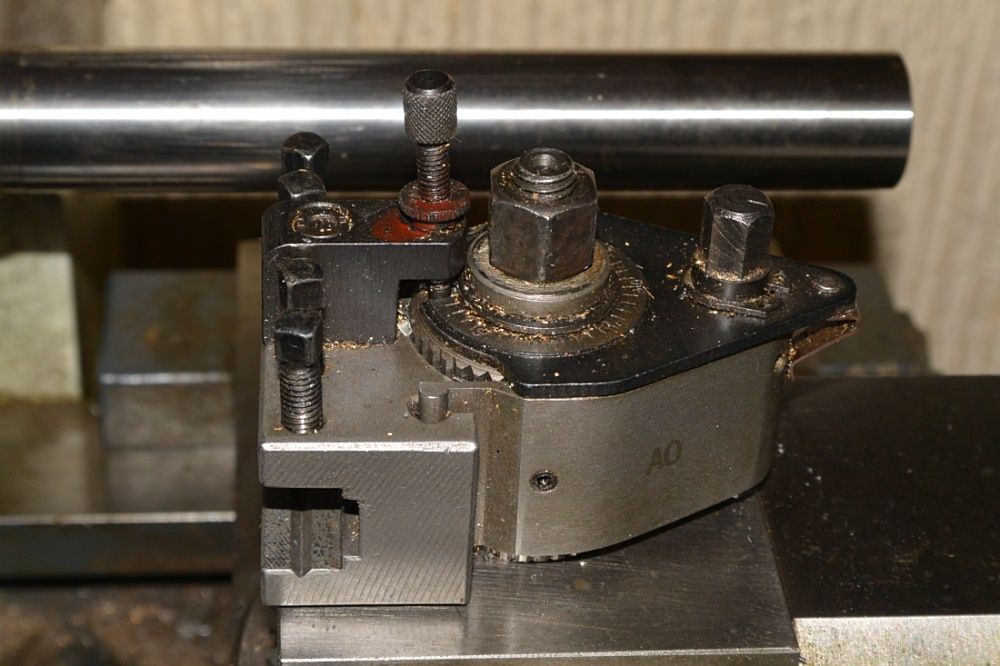

They do have one interesting fix of a problem home made qctp can suffer from so might be of interest to some. The pillar the entire holder sits on has a relatively low surface area at the bottom compared with other types suggesting that they would need tightening down more firmly than others. They have added a few sharp shallow rings / serrations to the underside of the pillar which actually dig into the surface they are mounted on. If they didn't do that they probably would slip/rotate under high loads. I had wondered how they get round that. The only aspect I was not clear on is compatibility between different makes.

A disappointment for me is that the holder has to be removed to set an angle as the cam action that pulls them back firmly hasn't sufficient movement to clear the serrations. This is fiddly compared with what I do with a Dickson type. According to mood I gauge by eye, use the face of the chuck to set a parting off tools square or even a square or protractor against a face of the holder using the outside of the compound slide as a reference for any angle.

They are a nice cheap alternative to the ratchet indexing that has been fitted to the bottom of some tool holders in the past and give more angle settings as well. The tool holder doesn't need rotating in one direction like those did either.

For me, as I mentioned I run 2 lathes and common holders make more sense than having 2 types. The only way I will get a 16mm boring bar on this machine is to make a holder myself, just like my Boxford due to it coming with a lot of Myford holders. It would cost way too much to replace those and just why should I remove a hefty clamp on knurling tool from it's holder to fit into a multifix one for instance. A number of other things too.

It turns out that it isn't genuine Multifix anyway. According to lathes co they are stamped with that if they are even in the USA where they may have Emco on the side. They were probably supplied by Wabeco but not marked as such. The price of the body is £178, 5 piece set (3 holders) £383, that's what the lathe came with. The lathe chucks are by Bison.

I'm still hoping for an answer on myford 7 ml10 / speed 10 aprox tool height above the compound slide top and fixing bolt diameters In case one looks more sensible for adaptation.

John

–

Ajohnw.