Posted by David Taylor on 27/08/2018 00:37:53:

What do offset and radial machining mean, and what is a backplotting program?

I don't have a high speed spindle. Do you think it makes much difference? You're spinning the cutter almost 5 times faster than I can.

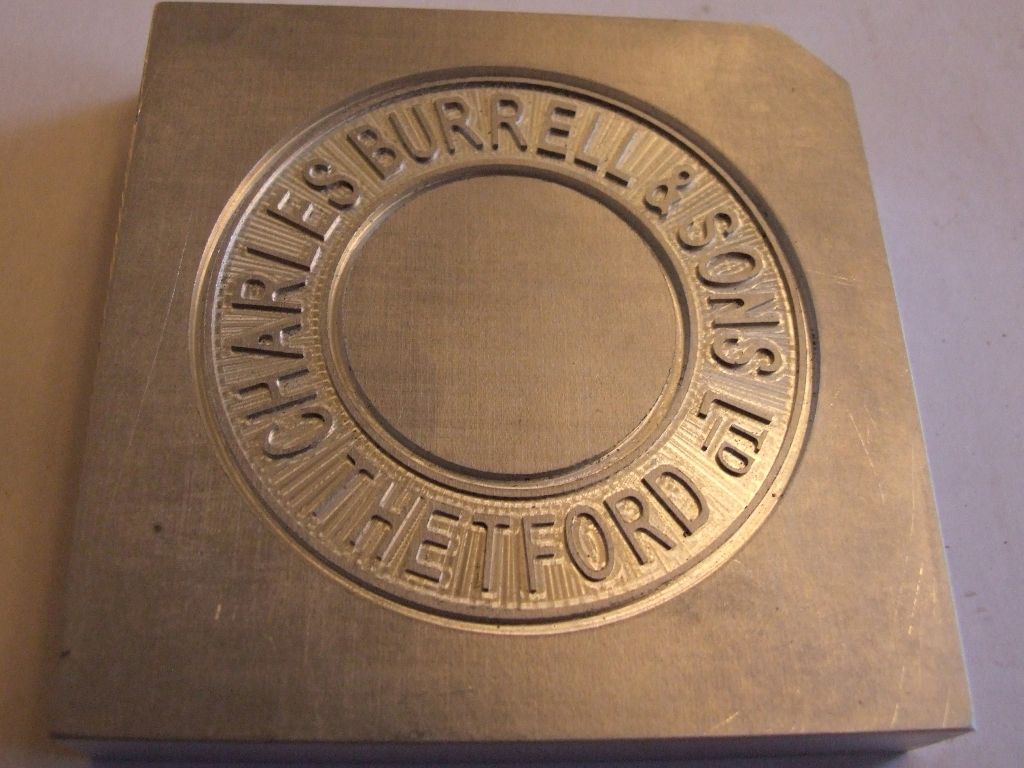

If you look closely at the bottom of the ring where the lettering is the toolmarks are radial to the centre of the plate. So the tool path tries to cut always on a radial. This makes sense for a shape like this and is quicker than other options. At each level a clean up pass is made that profiles the circular edges and round each letter to clean up areas not covered by the radial toolpath. However, when pocketing out the internals, for example the letter O, a radial toolpath isn't appropriate. I initially used a radial toolpath because the operations were cut 'n' paste from the first toolpath. The area to be removed is small so a radial toolpath does a lot of small movements as the pocket is not truly round. An offset toolpath enters somewhere in the middle of the pocket and then moves outwards in a series of parallel paths, the distance per sideways step being set in the CAM program. I set it at 75% of tool diameter. Although the change of toolpath only saved a few seconds per pocket that adds up over the number of letters that have internal cavities and over five levels to get the final depth. It probably saved 15 minutes or more overall.

A backplotting program reads in the G-code and plots the toolpath from it. That is different from CAM programs that display the toolpath they think they will use based on geometry, rather than that generated by the G-code the CAM program generates. Although not common I have had issues where the toolpath represented by the G-code was not the same as the toolpath the CAM system thought it was using. The backplotting program also gives a sanity check on maximum travels in each axis so you can double check there are no unauthorised moves outside of the machining envelope that will let the tool hit clamps or mill into the table. I use a program called NCPlot. I bought my version, a few hundred US dollars; they may do a simpler free version?

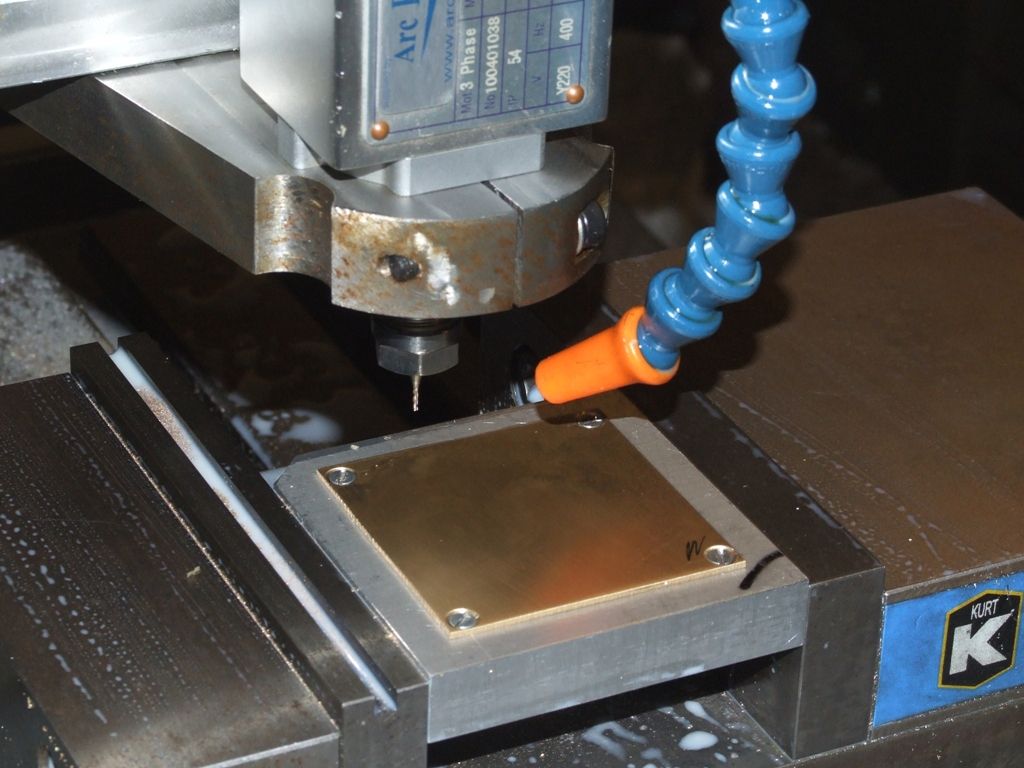

Some years ago I spent a lot of time trying engraving on the Tormach. The results were a failure and I came to the conclusion that the spindle speed simply wasn't high enough. I dithered over a high speed spindle for quite a while. Then I noticed that ArcEuroTrade had stopped selling them. Fortunately I was able to do a deal to buy a demo unit plus inverter. Mounting the inverter and wiring was simple, but I had all sorts of issues with the odd Chinese connector on the motor itself. In the end I binned it and bought a proper shielded connector of similar size from RS. So not a straightforward installation, even for a professional electronics engineer!

There are two reasons why the high speed spindle is essential, in my view for small cutters. The chip load I ran on the nameplate milling was about 0.005mm per tooth. At 5000rpm that would be a feedrate of 60mm/min. So the machining time would have been nearly seven hours per nameplate. For me that's not acceptable. When I modelled the bevel gears for my governor at 5000rpm the machine time was nearly 20 hours per gear. The other issue is to do with axis movement. I think the resolution per step of the Tormach is on the order of a tenth or so. But when setting up I find I can make several clicks on the jog console without the axis moving. Then when it does move the distance may be bigger than the nominal step size. For a small cutter running at slow speed that can be a significant variation in chip load, resulting in broken cutters. I suspect that was my basic problem with the engraving trials. If the cutter is running much faster with a consequent increase in feedrate then any small inconsistencies in the axis movement are proportionally much smaller and less likely to break the cutter. So far I've got about 40 hours of machine time with 1mm cutters, and I've only broken one, where I boo-boo'd on the vertical offset and it was trying to cope with a DOC of 0.5mm and full width.

Personally I find the high speed spindle essential for small cutters. Whether it is of use for you will depend upon the type of machining you are likely to be doing.

Now off to do an aircraft inspection, and then I'm afternoon tug pilot.

Andrew

Tim Taylor 2.