Hello everyone.

I've used the search function but haven't found any results.

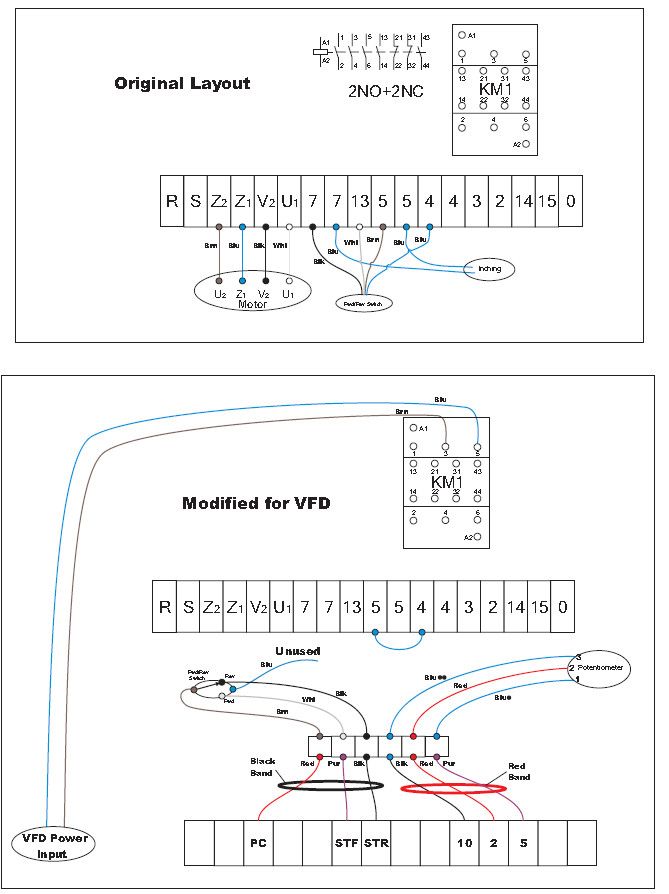

I'm converting my little Hobbymat MD65 lathe to VFD and am looking into how to control the VFD. I'm sure the keypad on the VFD is meant only for setup/testing, as the buttons are very small and don't have a good "feel".

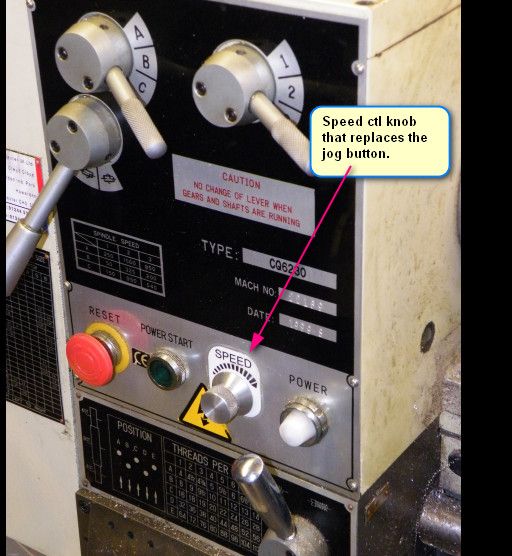

The simplest option would be to just use the two 2-position rotary switches on the lathe, and just add a potentiometer to the panel for speed control. Perhaps an emergency stop button would also fit on the panel. Do I want extra features, such as e.g. Jog, Fast-Stop (dynamic braking)? Would these be useful on a lathe? (maybe for screw-cutting? although a carriage auto stop rigged to the Fast-Stop input of the VFD would be more handy)

The second option is an external remote / pendant / control box, which can be sized to include all the controls I could want, perhaps even an integrated tachometer.

It would be nice to hear opinions and stories, and to see pictures of what people are using to control their VFDs.

I would also like to get information on which parts you would recommend to use for the buttons, rotary switches etc.

It seems that in the industry, 22 mm (or is it 22.5?) or 30 mm modular controls are used. An "operator" is the user-facing part, and is easily replaced, while the body itself sits under the panel. There is 1 or more contact group (NO or NC) clicked into the body, also easily replaceable. It all sounds very nice, however it's quite expensive (a single complete switch can be around 20 EUR or more, potentiometers are usually the most expensive, running into 50-100+ EUR), and also there is a mind-boggling combination of parts available. I couldn't find an online shop that would present these parts in a way that is easy to comprehend. It seems one must study manufacturer's catalogs and then, knowing the exact part numbers required, order them. I understand these are industrial controls rated for high voltages and currents, adverse conditions, rough handling, and frequent usage for long periods. However, none of these concerns seem to apply in a hobby home workshop (and VFD control circuits use 24 VDC with very low currents). I'm sure the controls can also offer nice "feel", which is important, but is it worth the high cost? It just seems weird to spend more money on controls, than on VFD and motor (I got a used VFD for 50 EUR and a new motor for ~100 EUR). But if it makes for good user experience = happy working, perhaps it can be a worthwhile investment. If you like these controls and advise me to invest into them, can you recommend particular brands / model names, and shops/suppliers, and how to find all the necessary part numbers?

I've also seen significantly cheaper 22 mm push buttons and switches on eBay (from China), usually sold by vendors who sell all kinds of stuff and don't even have a proper store front. I didn't find it easy to find a matched/harmonized set of push buttons (start, stop, maybe jog), rotary switches, emergency stop button. If you had a good experience with such controls from eBay, AliExpress, or somewhere else, can you recommend sellers / brands / model names?

Considering that VFD control circuits are 24 VDC, many automotive switches (those rated for 24 VDC) could also be suitable, and they can be quite cheap. There seems to be such a multitude of those (many of them looking fancy, with various color LEDs, which I think wouldn't make sense on a lathe), that I don't even know where to start looking. Is this advisable? Can you recommend good shops / sellers?

Any advice on the potentiometer? The industrial ones seem to be crazily expensive, I'm thinking about just getting any regular single-turn linear taper potentiometer. The VFD I got (Yaskawa V1000) specifies a 2kOhm pot.

I wonder whether to install a tachometer display on the lathe itself, or on the control box.

Last but not least, what would be good for the enclosure, and how to produce a decent looking and durable legend?

Gene Pavlovsky.

I think I'll go with 22 mm as these would suit my large hands / fingers better.

I think I'll go with 22 mm as these would suit my large hands / fingers better.

kcAAOxy4XNSOXKm from ebay.

kcAAOxy4XNSOXKm from ebay.