Chris,

I have made a 'few' of those 'screwdriver jobs for mobile use – I used a 100mm schedule 4 PVC tube – had a wall thickness of 6mm. Is was light grey in colour, and To be sure of it's dielectric suitability I placed a 100mm section in the microwave, on high power, with a cup of water, for 10 minutes. It was mildly warm and worked ok in the application. Other tubes I tried – 100mm underground PVC drain pipe, a cream colour before the uWave test, dark brown and HOT after 4 minutes, a 75mm gutter down pipe, white, which also passed the test. I would have used that, but the wall thickness was onlt 2 or 3mm, difficult to cut the thread. I also made one using 40mm schedule 4 PVC tube that passed the uWave test – beware the typical house-hold 40mm PVC grain pipe – that stuff is very lossy.

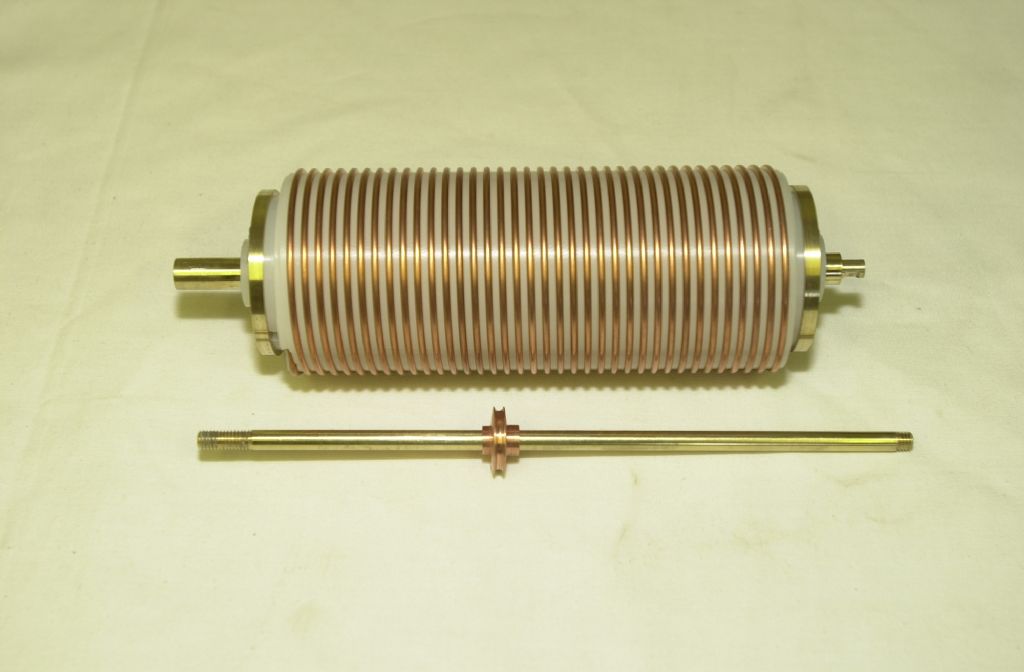

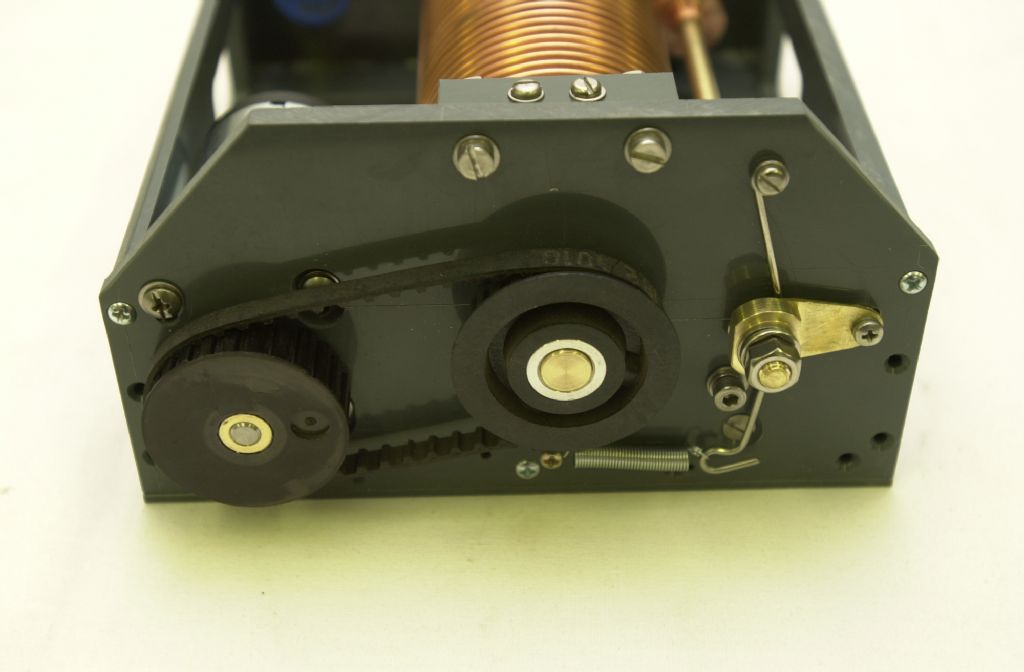

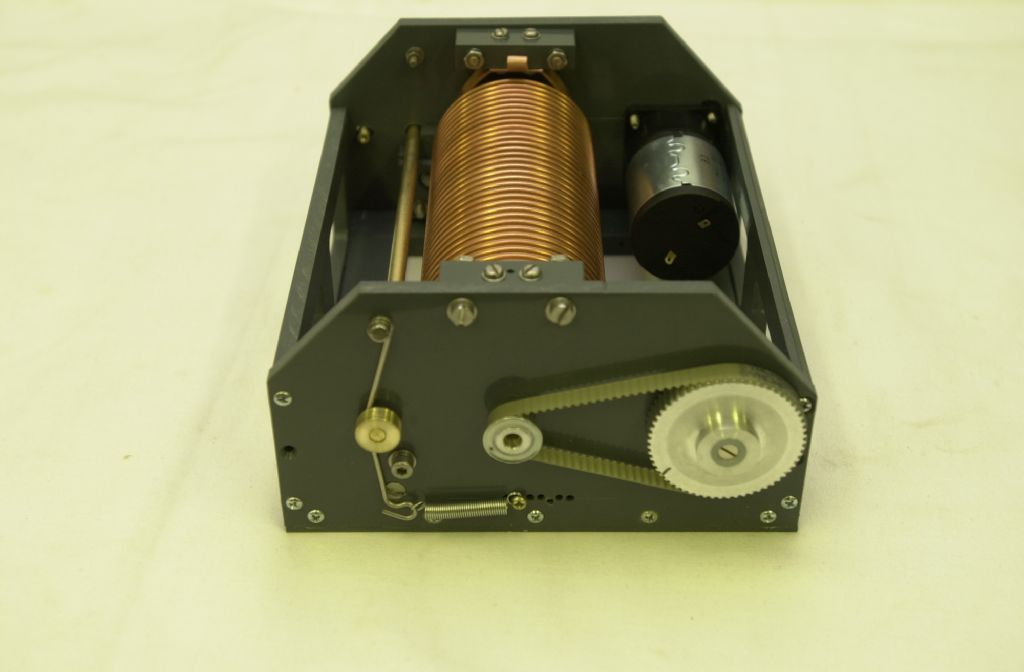

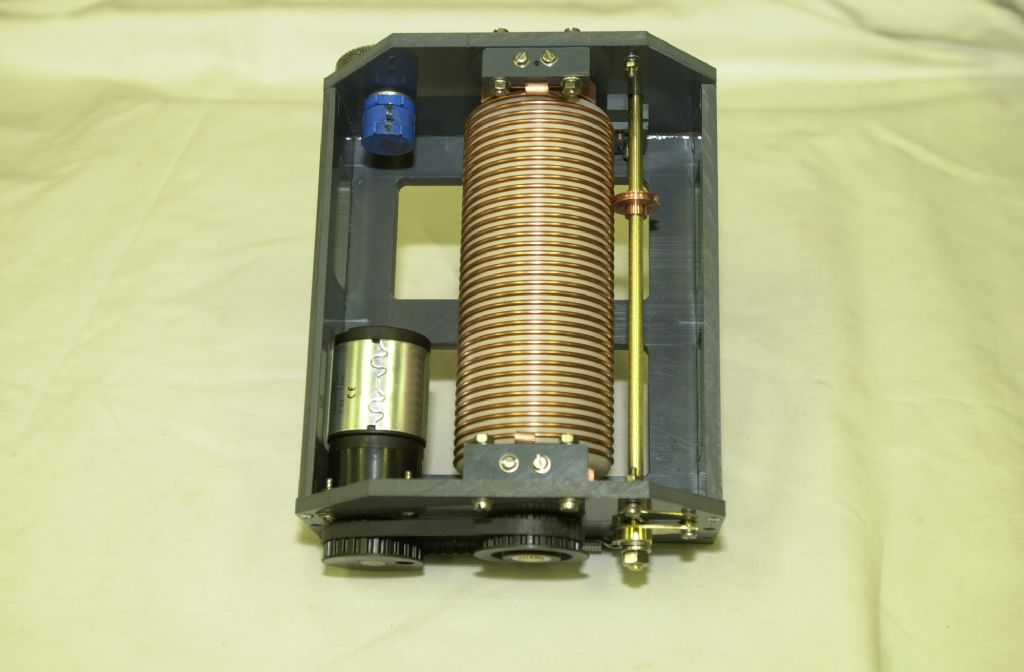

I then made another using a solid 40mm x 300mm long Polyprop bar, and silver coated wire, with a roller contact – the bar rotated in bearings on a Polyprop through-shaft..It was a work of art, and the Hustler beat it..Was nice yo be able to change bands from the drives seat, but lost too many weak contacts – also, it was very difficult to eliminate the commutator brush noise on the bands – the motor is right neat the coil…

GPR is not good – the glass is fine, but the (general purpose ) resin is not. Is has high losses and used as a former in an HF amplifier tank coil, @150watts RMS, it got hot and softened. Polyester resins are worse..

Not sure how you intend making the sliding contact on the coil, but I used some of that berryllium finger strip, like on the peripheral inside of RF shielding cabinet doors, wound in a circle around the coil – that worked well.

I gave up on the antenna in the end – it was far more work that is gave back in performance – the good old hustler worked far better!

Have Fun..

Joe

Michael Gilligan.

Michael Gilligan.