Posted by John Baron on 10/08/2019 20:17:26:

.

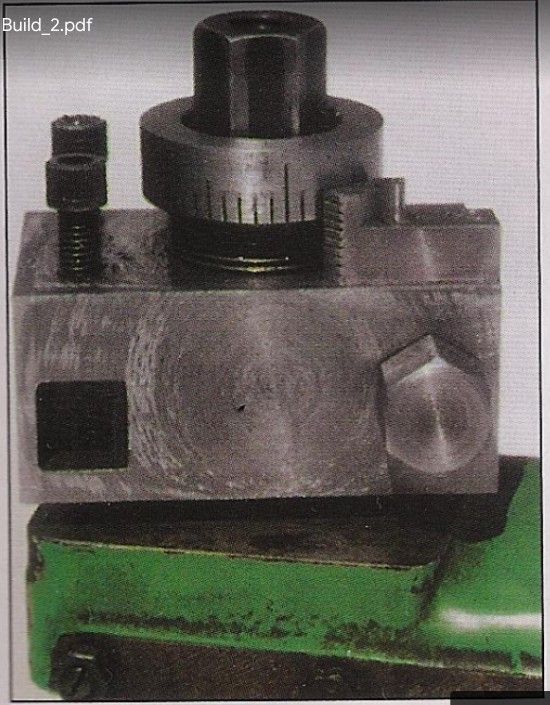

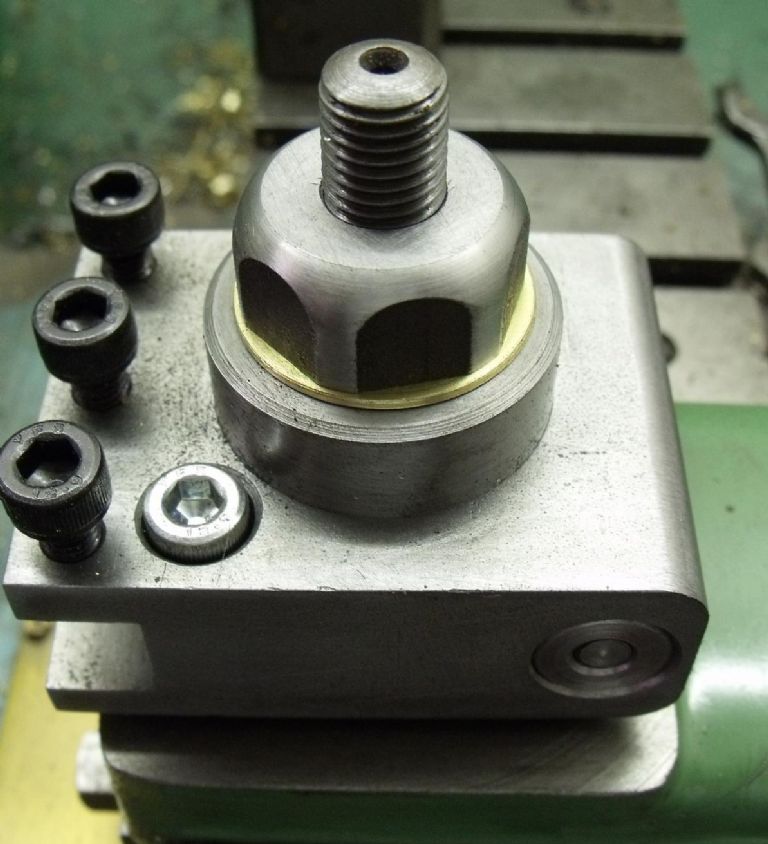

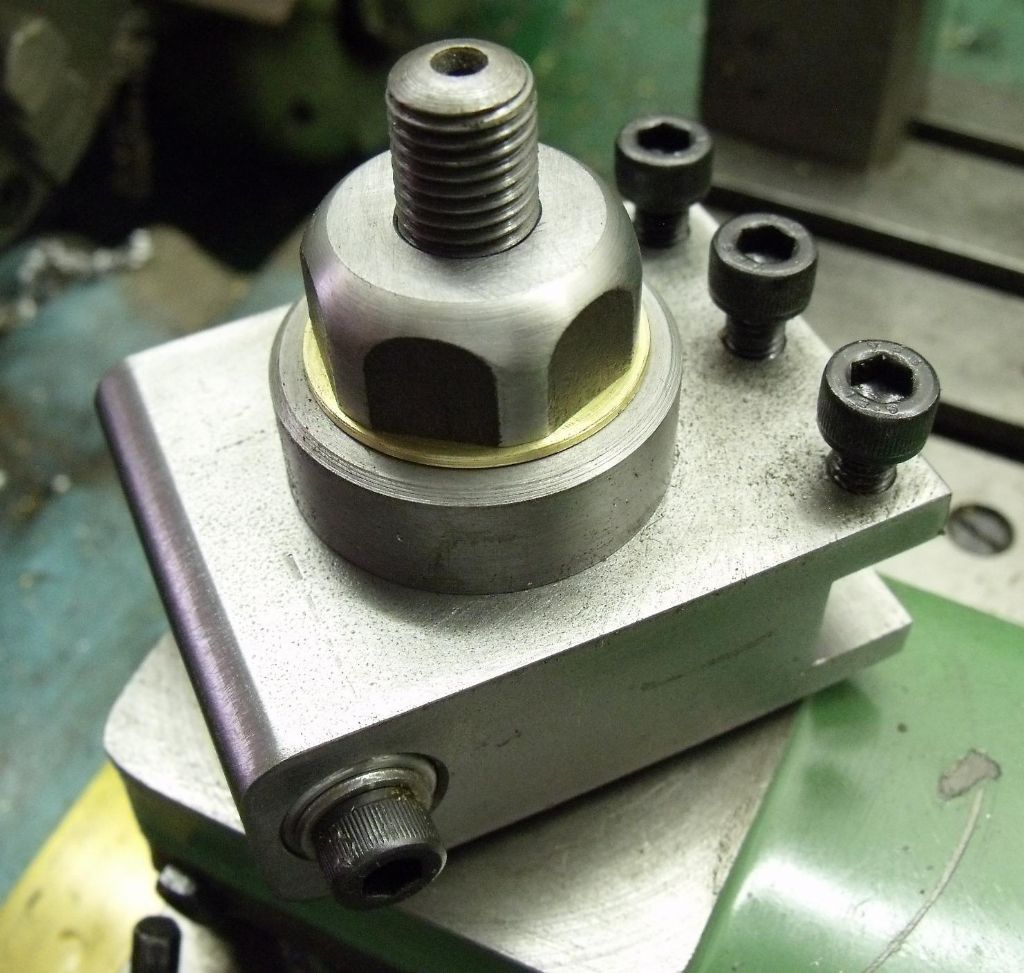

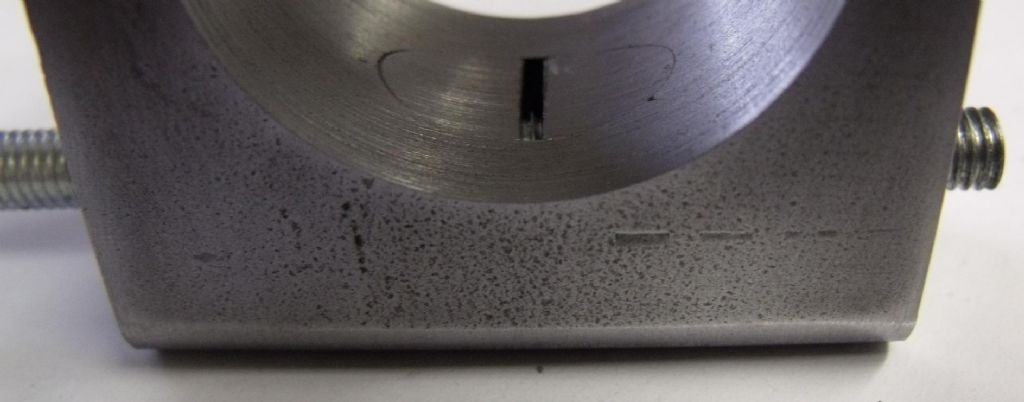

… My drawings are based on the original Van Norman 1880's patent document and not on the later modified ones using a slit and a pinch bolt to clamp the tool block. It was Norman's original design that was used by Rolls Royce in their experimental workshops.

.

John,

I have been searching for that Van Norman patent, and failed

[found several others by him but not that one]

Then I stumbled across a note by you, on another forum:

[quote]

Hi Guys,

I can't find the original references to the "Norman Tool Holder" But the original didn't use a bolt to clamp the holder to the post. That drawing in the PDF is modified to use a clamp bolt.

The original design used a split pinch clamp that actually closed on the post directly. Yes it had a screw through it which pulled the two half's of the clamp together. This also allowed a further modification of a handle to clamp the holder without any tools.

[/quote]

.

So, my question is: Did you find the original references ?

and, if so, could you please share the patent number …

I am familiar with the clamping method: I would just like to have a copy of the relevant patent on file.

Thanks

MichaelG.

David Davies 8.