The future of casting kits

The future of casting kits

Home › Forums › General Questions › The future of casting kits

- This topic has 44 replies, 21 voices, and was last updated 24 January 2022 at 10:08 by

Roderick Jenkins.

Roderick Jenkins.

-

AuthorPosts

-

18 January 2022 at 13:46 #581022

JasonBModerator@jasonb

JasonBModerator@jasonbRather than Hijack the "Whatch this Space" thread with further discussion of CNC machines casting kits I'll repost something I wrote on another forum a few months back:

I have mentioned it before a few times about being able to resurrect some of the older designs where patterns have been lost or if they are still knocking about and usable the owner can't find a foundry to cast them. With modern CNC it should be possible to reproduce these castings with the added bonus of none of the usual casting defects such as blow holes, undersize parts, hard spots, over fettling , etc and leaving the builder to do the final work such as finishing bores, drilling and tapping of holes etc. much as they would with a traditional casting

This video of E T Westbury's "Whippet" being machined would be the perfect example if the machining were stopped before the final holes were done, I'm sure they would sell

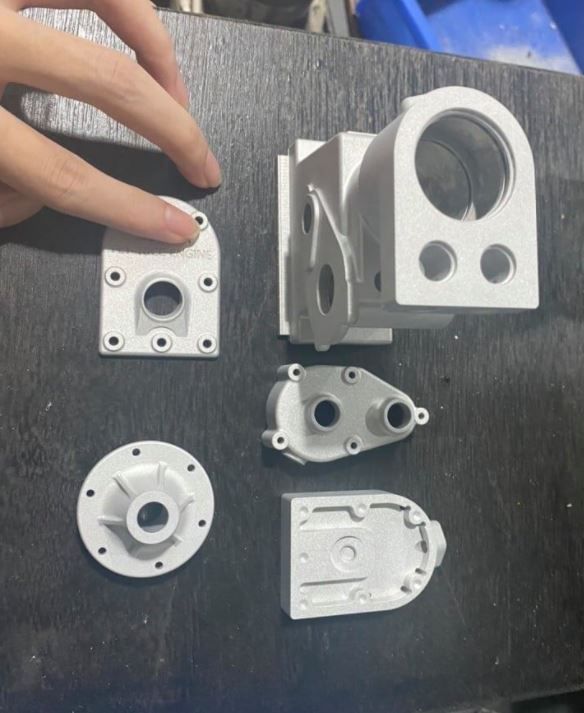

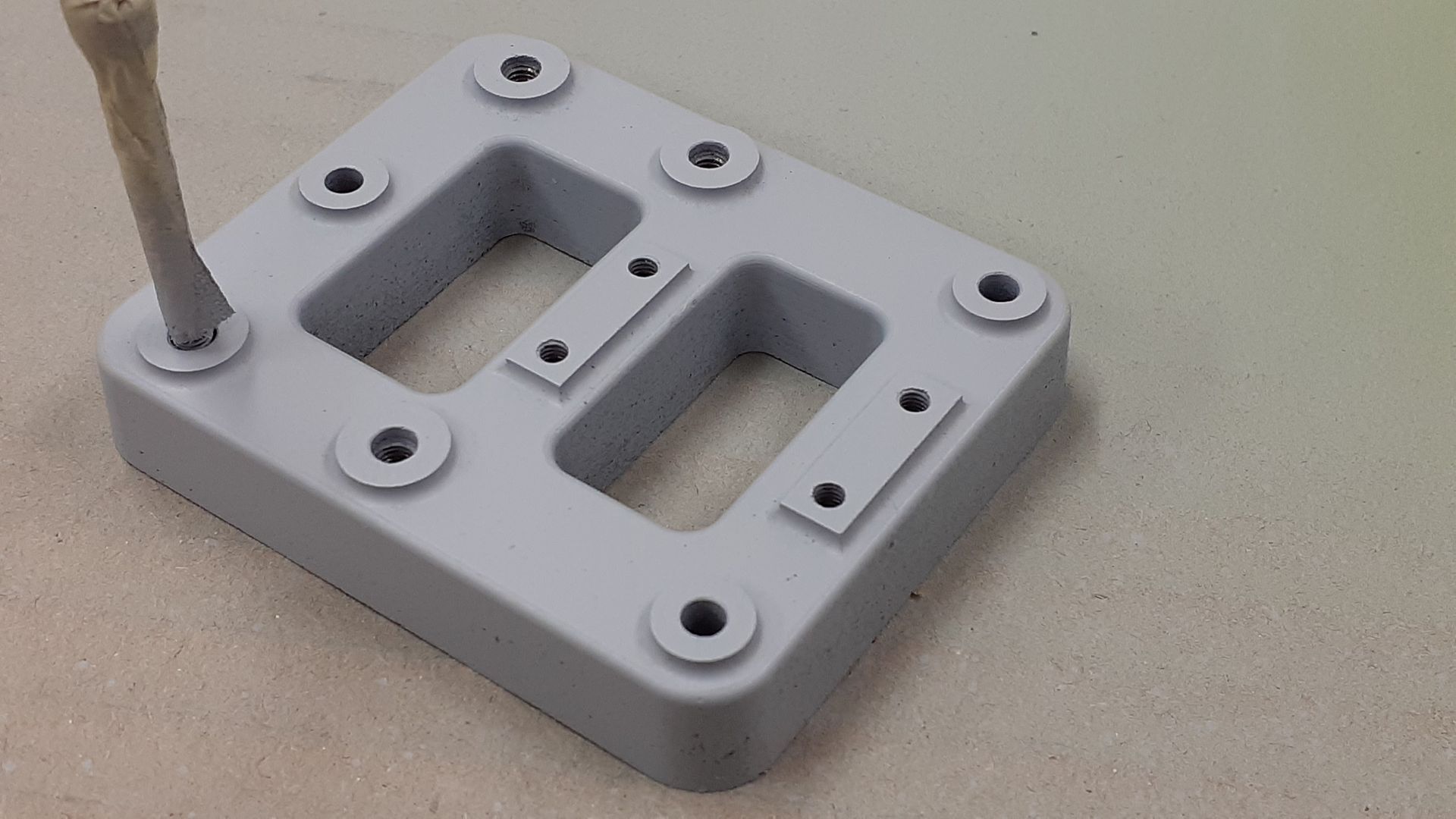

And what a set of "castings" may look like

I have enquired about costings but as the company can produce a fully working engine for $499 I should think that the castings would be quite favorably priced compared with what is available in this case from Hemmingway at about $200. If so it would be nice to see some of the "lost" engines from the likes of Wall, Westbury and the Motor Boys plans being made available to those who like to build them rather than just the collector of ready to run engines.

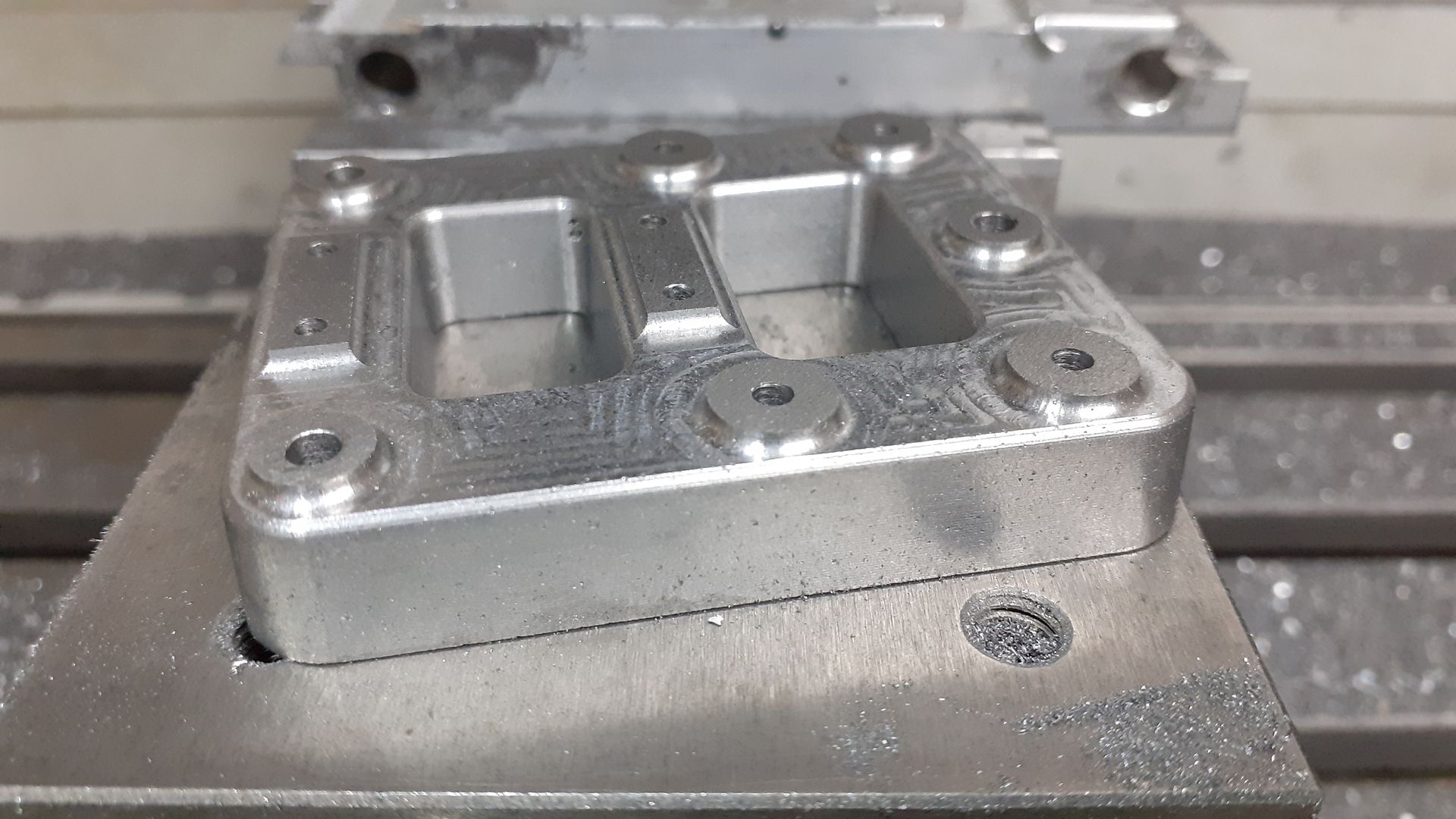

A couple more examples of my own making, a bedplate for a small long out of production steam engine

A flywheel again from a 1930s design long lost.

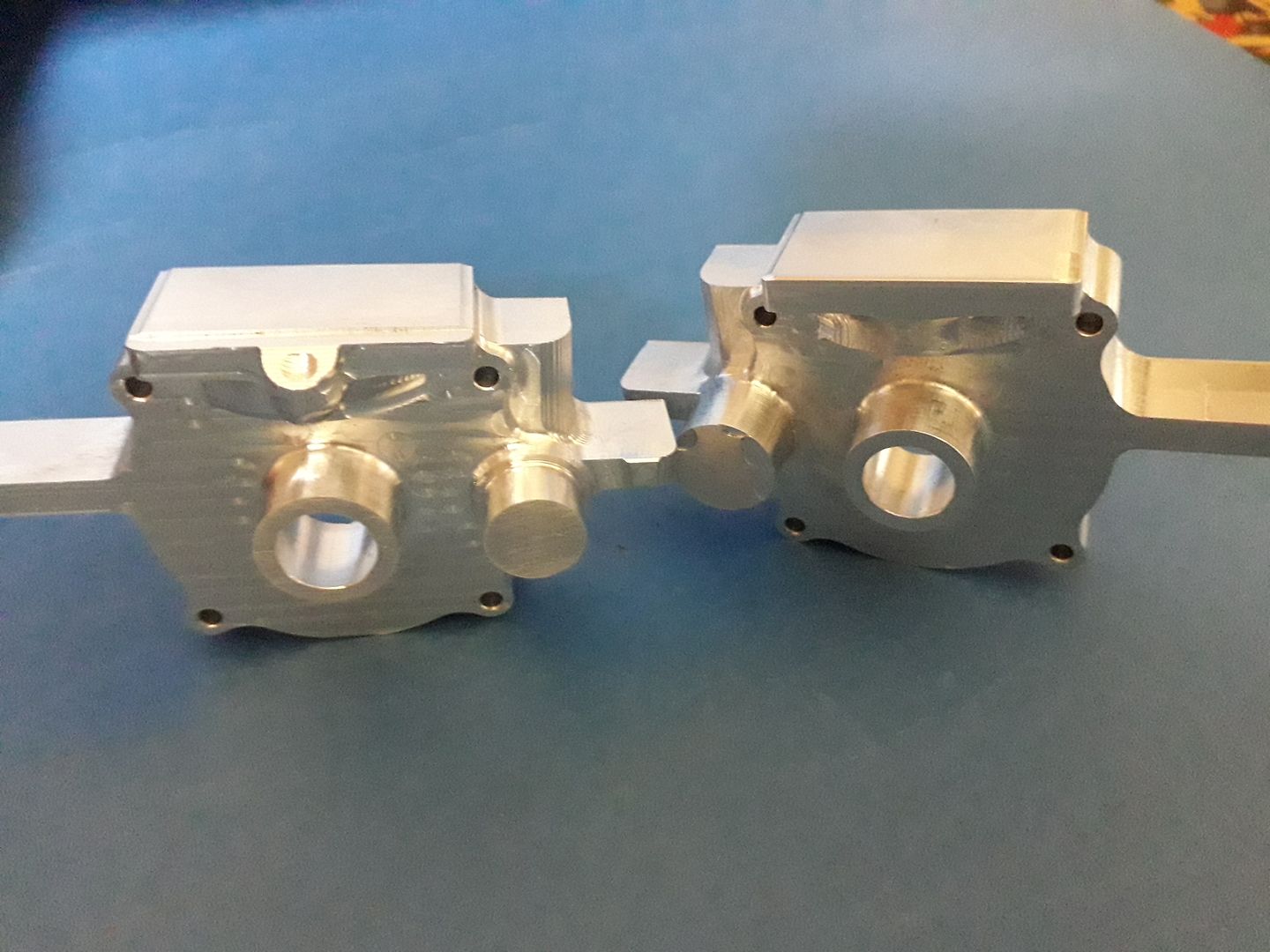

Crankcases never a commercial casting but taken from a 1936 magazine design

There seems to be a market for part machined barstock kits from the likes of Bengs so it would only be a small step further to have some more shapely parts. I think even Stuarts are supplying some of the smaller items CNC cut these days like the valves for the 10series so it may not be as far away as you think.

Discuss.

18 January 2022 at 13:46 #28532 JasonBModerator@jasonb18 January 2022 at 14:04 #581026

JasonBModerator@jasonb18 January 2022 at 14:04 #581026 JasonBModerator@jasonb

JasonBModerator@jasonbLeaving the more modern methods to one side there is also the fact that far more home workshops now have milling machines and access to relatively cheap tooling so a lot of parts that were at one time provided in a casting set can quite easily be made by the builder where they may once have struggled to cut the part from solid on a typical Myford or it would simply have taken a long time compared to on a mill.

As an example I'm in the early stages of making my version of a reasonably popular engine that is available as a set of castings c/w materials and fixings. Although I could make all the parts I have opted to buy (well Xmas present actually) the cylinder and flywheel castings as these are probably the two parts many would find the hardest to make themselves and be put off the whole idea. The rest will be from barstock but won't have that chunky polished up final look. Cost will be approx half of less of the kit and mine will have more detail and period features. But you will have to wait for another thread on that one or maybe I'll write it up for ME.

18 January 2022 at 14:54 #581032SillyOldDuffer

Moderator@sillyolddufferSeems sensible to me .

Pouring cast-iron into a mould had many advantages in the past, but the method has largely been displaced by several other techniques. Once every UK town had a foundry, now they're rare. My nearest is hi-tech, specialises in aero-space, and doesn't do small value orders.

Fortunately, casting is only one way of shaping metal. Never occurred to me a CNC program could produce much the same result as a mould, but of course it can!

Maybe in future all 'castings' will be CNC cut from continuous cast-iron, and Model Engineers in 2050 will wonder why we put up with hard skin and blow-holes.

Dave

18 January 2022 at 15:17 #581034Luker

Participant@lukerI’m honestly surprised sand casting kits are still available. At the very least modern casting kits should go the investment casting route. With modern 3D printed patterns produced from very reasonably priced printers there is no reason for an investment foundry to not add a few parts to a tree. Today most engineers would tend towards CNC or investment for components in the size range of model engineering, especially lower quantity items.

Personally I like the challenge of getting the calculations right for the risers and messing around with the chemistry of the melt. I can’t remember the last time I got hard spots or blow holes. Casting has been part of the hobby since the beginning, as an additional skill to be honed. Not sure it makes sense commercially though, especially if the suppliers can’t get the castings right.

Maybe in the future G-codes will be sold instead of plans and little home CNC units used to finish models while watching 3D movies. Can't wait…

18 January 2022 at 15:40 #581039

18 January 2022 at 15:40 #581039 PatJParticipant@patj87806

PatJParticipant@patj87806The "castings" that Jason shows above say to me "investment casting".

Perhaps the dividing line is between gray iron and tempered 356 aluminum; ie: tempered 356 cuts pretty well, and would probably be easier on a CNC machine.

Gray iron machines well too, but it seems like more power is required.

From a mass-production standpoint, investment casting is the way to go.

For one or two off production, CNC would seem to make sense as an option to castings.

I have followed one fellow who is using a special 3D printer filament that burns out cleanly with an investment process, and he made some cast iron pieces that looked to be die-cast quality (he sent me one).

I don't have blowholes or hard spots in my iron, but I do understand that some kits have this problem.

CNC is definitely changing the game a bit, but I think in the end, 3D printing will have a bigger effect by printing patterns.

Just my 2 cents.

.

18 January 2022 at 16:40 #581045Iain Downs

Participant@iaindowns78295I chose to build my first engine out of barstock rather than casting and the reason was cost. What I've built (which may someday run) is roughly equivalent to a Stuart 5A. Castings would have cost me £800. My actual material purchases were nearer £120 – £150 – and spread over time.

Apart from the joy of starting from scratch, it's a lot easier to get a bunch of £50 quid purchases around the missus than one £800.

I expect it's taken me 3 – 5 times longer, but I don't charge for my time.

CNC would have made it much more palatable of course.

Iain

18 January 2022 at 18:34 #581072Another JohnS

Participant@anotherjohnsI'm finishing up an old set of castings, from Dave Goodwin back in the late '80s, which is a change from the Kozo Shay (no castings) Most of the castings have been machined already, mostly in the 1990s.

With my CNC machines, I think castings now are more hassle than they are worth, IF YOU HAVE THE CNC MACHINES and know how to use them. Doing the motion plates for this were a pain, would have been much faster to just machine from raw materials. Finding blowholes (one motion plate, a cast angle was holy), and too-aggressive fettling needing building back up (cylinders)…

Jason, most of our club still work in imperial, fractions, and pencil and paper, and are not going to change. There are 3 of us with CNC machines out of 25ish members. Another person just ordered a Taig mill to convert, so 4 out of 25??

There's still a market for castings. Ask again in 10 years.

18 January 2022 at 18:43 #581073

18 January 2022 at 18:43 #581073 JasonBModerator@jasonb

JasonBModerator@jasonbMy main thought wa sof suppliers providing ready CNC machined "castings" the point about selling or providing G-code came up in the other thread as well as here, I don't think this is a very good option for a couple of reasons.

Firstly it would be a bit like putting your home movies on a VHS tape and then selling them to someone with a Betamax machine. There are many different machines and systems out there and each needs a slightly different code for example the Mach3 code that the post processor in Fusions CAM produces would not run straight off on a machine that was running LinuxCNC. There are probably a couple of 100 options for the different systems that F360 can generate the code for so not really practical to send out so many files.

Secondly even if two machines were running the same software just like in the manual home workshop you would not be taking the same cuts with a small hobby machine as you would with a Bridgeport so the g-code needs to be produced with that in mind. For this reason it is better that the individual enters the size of cutters they have as well as the size of cut they can take and at what rate.

If one was providing drawings and digital files for someone to do all the machining themselves then it would be better to use a common file type such as a STEP file either of individual parts or the whole assembly. As an example that photo of the two crankcase halves are from my Midget engine, I was contacted by someone who also wanted to make on and being the nice guy that I am I just sent him a step file exported from my assembly model. He was able to open this and then access the individual part sin his CAD, a couple of clicks and he had scaled it back up to the original engine size and then he ran the various parts through his CAM and produced the code to make the bits on his own machine. I did not even have to produce a set of 2D drawings, he just made them as he needed.

18 January 2022 at 18:52 #581078Zan

Participant@zanMy 3” Atkinson uniflow engine was entirely from bar stock a very cheap option, the whole engine cost less than two bronze valve housing castings for the standard design. For the diff the grease cover was a £36. Ish casting. I used a plate of 100 mm x100 mm offcut of 8 mm plate Bar stock is often easier to hold

18 January 2022 at 19:00 #581082 JasonBModerator@jasonb

JasonBModerator@jasonbPat, yes the CNC will produce a much better finish than the average sand casting even oil bonded ones so a lot less fettling to do to get a good surface for paint. I think those whippet ones have been bead blaste dto remove the visual machine marks though I expect it is almost impossible to actually feel what can be seen.

That bedplate for example was cut from poor quality salvaged grey iron and what you see is straight off the machine, there is a 3deg draft angle on the vertical sides made with a series of cuts as the CNC ramped the cutter down gently as it went round and round the contour. I just lightly deburred around the tops of the bosses with a bit of Emery and this is it straight after the first coat of primer, the few dark specs are small voids in the iron. You won;t get that straight out of the sand pit.

There is no real dividing line between metals, the bedplate and the flywheel were cut from solid iron, the crankcases from 6082. In much the same way as you would on a manual machine a slower speed and lighter cuts are used on iron and steel than you would with aluminium and non ferrious. This assumes a rigid enough machine, a lightweight router type machine may not cope so well with iron but it's much the same for the home foundry as not many can get upto iron casting temps but aluminium is not such an issue with a small furnace and burner.

For decent investment casting then it's better to print using a wax fillament and melt it out than a plastic that has to be burnt out as it's easier to join them onto trees and you don't risk leaving ash in the mould

18 January 2022 at 19:14 #581084 JasonBModerator@jasonb

JasonBModerator@jasonbI would not say there is not a place for castings in the future, particularly on the larger subjects like 6" traction engines where you would be turning a lot of metal into swarf and wearing tools at the same time not to mention the size and running costs of a machine that at least commercially would be tied up for several hours on a single part. That does not mean to say the patterns could not be 3D printed our cut from foam on a large gantry of 3D router.

On the cost front one thing I do find with some of the casting kits is that you get cast parts almost for the sake of it where there is little or no reason for the part to have been cast. Take as a recent discussion on another forum where a member was asking about options for a flywheel to go on a triple expansion engine, another member said a casting would save material and said it might but would not save money.

Having just done a similar disc flywheel for the Simplex I went looking at the cost of a similar sized cast one, a well known supplier had one available for £11.68 just a disc with a recess running around either side which unless the two halves lined up well would end up with one side running off if you set the other to run true unless you also machined the recess to get them concentric. In which case you may as well machine from solid, the bit of CI bar cost £1.74 so for very little extra work and maybe grinding up a tool what is the point of a casting for a part like that. Piston blanks and cylinder covers that are just discs also come to mind with the added higher chance of a thin cylinder cover casting being chilled or is that what you are paying for?

18 January 2022 at 21:59 #581112 PatJParticipant@patj87806

PatJParticipant@patj87806I have to agree with Jason.

On some (perhaps many) casting kits I have seen, many of the parts are more like blobs of cast metal, with little in the way of detail.

I saw a discussion on another forum the other day about how it is getting more and more difficult to get foundry work done for model engine casting kits.

One of the reasons I learned how to cast gray iron is so that the technology would not be lost to the model makers and others who may want to use it.

As far as cost, I have not really kept up with it, but a few costs are as follows:

(prices are so volatile now that I am not sure how accurate this will be next month)

1. Two bags of Mizzou refractory, perhaps $275.00 shipped

2. Two Sonotubes, $25.00.

3. 2.5" muffler pipe, $12.00.

4. Spray nozzle, $30.00 shipped.

5. sheet metal exterior (used 55 gal drum), ?

6. Miscellaneous bits, steel pipe, fasteners, etc. $100.00

7. Clay graphite crucible, $100.00 shipped.

8. Plastic fuel container $25.00.

9. Fuel line, $25.00.

10. Air line $20.00.

11. Scrap gray iron, one place priced it at $0.40 per pound. I found some motor end bells for free.

12. Metal to fabricate lifting tongs, $25.00.

13. Metal to fabricate pouring shank, $25.00.

14. Metal to make ingot molds, $25.00.

15. Wood to make flasks, $50.00.

16. Foundry sand, depends on what type you use, perhaps $0.20 per lb.

17. Fuel cost, I run diesel at about $3.50 per gallon, burning 2.7 gal/hr, with a melt generally being 1 hour.

18. I have an air compressor, but if you don't have one, you have a few other options.

I did build my furnace and burner to last indefinitely, so spending a little more money initially pays off in the long run.

So adding all the above costs (not including labor), you could build a very nice iron furnace and diesel burner for probably under $1,000.00 US.

I paid $600.00 for a single casting kit (ball hopper monitor), and so you would not have to buy many casting kits in order to make your own foundry.

Of course some would pay good money not to operate a foundry; it can be very hot and dirty, but that part does not bother me; its about saving the technology and preserving it for future generations.

And I love to make my own iron castings, just because I can make castings that cannot be purchased anywhere in the world.

Here is the 3D printer filament that supposedly burns out cleanly (I have not tried it).

18 January 2022 at 22:09 #581113 PatJParticipant@patj87806

PatJParticipant@patj87806And here is an example of an investment casting using 3D printed parts in PLA plastic (not the good filament I listed above), with the tree and gates also printed in 3D.

This is an amazingly good result from someone's first try, and using PLA and not Polycast.I don't use the ceramic shell method because the slurry has a finite shelf life that is rather short (perhaps 6 months to a year ?), and there are multiple steps involved, such as repeated dips in the slurry with sand coats between, and a high temperature burn out in a kiln.I can cast complex parts using resin-bound sand, and a ceramic mold coat, and the iron castings come out of the mold with a clean shiny finish (I can beat anyone's iron casting surface finish right out of the mold with no post-casting cleanup or sandblasting).I did contact one of the US casting kit guys about a month ago, and I told him that if he lost all of his foundry suppliers, there was one more option for him, and that would be for him to make his own iron castings, since we have the technology to do this.For those not wanting to go the home foundry route, CNC machines make some nice work..19 January 2022 at 06:11 #581137Bill Pudney

Participant@billpudney37759When cast iron was a new material, casting it into new and previously unachievable shapes was one of the major benefits. Another was of course cost. It's really interesting (to me at least), that now the reducing cost of CNC enables the economic manufacture of previously unachievable shapes!! There's also the increased accuracy that machining a "casting" from solid brings, with none of the side issues of shrinkage, draft angles, inclusions, chill spots etc etc

cheers

Bill

19 January 2022 at 09:57 #581157noel shelley

Participant@noelshelley55608Hi Pat, Like you I got into foundry work to keep the craft alive. Having become quite successful at it I then took to giving talks and demonstrating the craft in the hope that others would have a go. My furnace was based on a spindrier casing and most of what I needed was made or recycled. Having a well equiped workshop of industrial gear did put me ahead of many. Since most of the work I took on was decorative I worked in brass or bronze my heat requirements were much lower than for iron, but from cold I could have an A6 crucible up to pouring temp in 20 mins on propane. Using greensand molding and careful pattern and mold making one can produce high quality castings that would in many cases make CNC look slow especially in aluminium, if you are trying to replicate a casting then draft angle is part of it, shrinkage can be controlled and, inclusions largely are the result of poor practice !.Never the lass we must move forward ! Best wishes Noel.

19 January 2022 at 10:15 #581162 JasonBModerator@jasonbPosted by noel shelley on 19/01/2022 09:57:49:

JasonBModerator@jasonbPosted by noel shelley on 19/01/2022 09:57:49:Using greensand molding and careful pattern and mold making one can produce high quality castings that would in many cases make CNC look slow especially in aluminium,

Noel would that include the pattern making time? The way I see it for a one off the time spent making a pattern would be similar to the time spent just cutting it from solid metal so why do it twice. Buy just cutting it straight from the metal you totally do away with the pattern making time so it would be wrong to just compare the melt and pour time without including time spent making the pattern. Not forgetting that apart from the odd tool change if you don't have ATC then you can be doing something else while the machine is cutting so actual time spent will be further reduced.

And if making the pattern the traditional way you are waiting for glue to dry, waiting for filler and fillets to dry, waiting for paint to dry and then unless you have a well vented workshop waiting for a dry day to fire up the outside furnace. All the while I can be sat in the warm clicking a couple of buttons.

Want a handed pair of castings that would be a whole new pattern traditionally, one click of a mouse and regenerate the paths and you are ready to cut the other hand with CNC and CAD/CAM

CNC cutting the patterns will also be faster than making by traditional methods plus you have a lot more versatility for example take a simple name plate. Traditionally you would be limited to available fonts and sizes of pattern makers letters and then have to carefully space them out by hand. Doing it with CNC or 3D printing you have 100s of fonts available in any height you want and can easily arrange them in evenly spaced lines or to follow a curve

Edited By JasonB on 19/01/2022 10:17:21

19 January 2022 at 11:31 #581171 PatJParticipant@patj87806

PatJParticipant@patj87806Noel-

That is an interesting story. I do feel like I need to pass this technology on to the next generation, and so I document everything I do.

Each individual has to find the engine building method that best suits their needs and desires.

I enjoy the foundry side of things, as well as hand-making patterns, although I use a lot of 3D printed patterns these days too.

The biggest advantage I see of casting your own parts as opposed to CNC'ing them is with foundry work, you get to play with fire. My mother would roll over in her grave if she saw me handling molten iron.

She was highly cautious, to the point where I had to hid everythign I did from her, in order to get anything done.

Sometimes my neighbors come over to watch iron pours, and they generally say "Man, this guy is crazy, but this is really cool to watch". The art iron folks over here have huge iron pour shows, lots of spectators, and major iron pouring events, such as at the old Sloss Furnaces in Alabama.

It is more than just casting engines; it is a big "thing" over here for lack of a better term.

.

Edited By PatJ on 19/01/2022 11:35:27

Edited By PatJ on 19/01/2022 11:36:10

Edited By PatJ on 19/01/2022 11:39:37

Edited By PatJ on 19/01/2022 11:40:07

19 January 2022 at 12:29 #581179derek hall 1

Participant@derekhall1Hi,

I wondered when someone was going to mention some of the useless lumps of "castings" that you get with some kits! e.g Jason mentioning a lump of casting that was supposed to represent a flywheel as a very good example.

So many of these components from a kit can be manufactured from the solid or built up and brazed/soldered.

However I am not going down the CNC route personally, I want to leave computers outside the workshop – all this talk of G -code etc just goes over my head! and have no wish to learn it and convert my manual machines to CNC, but I admire the work that these CNC machines can produce.

Jason mentions and I paraphrase.."click of a mouse" and "get on with something else while the machine is cutting" – I like twiddling the feed screws and enjoy manually making things that are generally one offs. I would sooner do this than sit down in front of a PC and write loads of code to be honest…

But horses for courses and all that, I am sure that if I was younger I would be getting into CNC and 3 D printers etc, but for me now pottering around the workshop is enough !

All the best

Derek

19 January 2022 at 12:59 #581182Martin Johnson 1

Participant@martinjohnson1If you are asking "Will suppliers who have sweated the value of the same old drawings and patterns for far too many years already be prepared to invest in reams of G code and all the associated fixtures?" Then the answer is a flat no.

If you are asking "Does CNC have a place in model engineering?. The answer is yes.

Personally, I CAD my own designs, make wooden patterns, buy castings, laser cuts, bar stock and machine it on 60 year old machinery.

Martin

19 January 2022 at 13:18 #581188 JasonBModerator@jasonb

JasonBModerator@jasonbMartin, as I mentioned earlier Stuarts are already providing things like the 10 series engine valves as CNC cut parts rather than lost wax castings so the answer is certainly not a flat NO. On another forum as Pat mentions where a few of the casting suppliers are members they were saying how hard it is to now find foundries that can do the work and may simply not be able to provide castings in the future so it's either give up or think of alternative methods, reducing the number of parts in a kit would certainly help in this respect.

Many suppliers already do laser and water jet cut parts as part of kits or along side their castings, I've also bought CNC machined parts from MJ Engineering for my traction engine so it's not much of a step to have the odd "casting" made by other means

Derek, I was having this conversation yesterday and my comment on the "watch this space" thread also applies as I too was put off by watching a demo where ages was spent manually writing a bit of code to do a simple machining operation, air cutting to test it then altering it. In the end I gave up waiting to see any swarf being produced.

However all is not lost as I can honestly say I have never written a single line of G-code and certainly have not had to learn it. Yes I have had to pick up how to use F360's CAM but it's a lot easier than having to type what would be tens of thousands of lines of G-code that are needed for some of the parts I make.

Yes I still like to twiddle the handwheels too and only use the CNC for things that it is best suited for and could quite happily operate a manual machine while the CNC is running in the background.

19 January 2022 at 14:10 #581197 BazyleParticipant@bazyle

BazyleParticipant@bazyleThe ability to make all the castings for eg a Stuart engine was achieved centuries before Maudlay provided the ability to finish them to an acceptable standard. As mentioned above let's not lose that technology. Shortly, in human evolutionary terms, we will lose the resources and infrastructure to make the ICs to run CNC machines.

19 January 2022 at 14:14 #581198 PatJParticipant@patj87806

PatJParticipant@patj87806I have used a mail-order 3D printed pattern, back when I did not have access to a good 3D printer, and the results were very good, but not really what I would consider cheap ($100.00 for one printed flywheel pattern).

I would probably use a mail-order CNC service (these do exist in the US according to one fellow I spoke with who build his own lauch boiler, and used it for the end plates).

There are certain small detailed parts that I really don't like to make, and this seems like a shoe-in for CNC work.

Small, tedious, repetitive work that needs good and consistent accuracy.

I do loathe the idea of learning new software though, but I think the modern CNC programs are relatively easy to use (I have not tried CNC yet).

Probably the breakpoint for me will be similar to when I purchased a 3D printer; ie: the Prusa was relatively inexpensive compared to some earlier manufacturers ($800.00), and the Prusa is a fairly reliable machine (although there is room for improvement).

If I could buy a rugged little CNC for under $800.00, and it came with software as easy to use as the Prusa slicer, then it may be game-on time.

.

19 January 2022 at 14:27 #581200David Jupp

Participant@davidjupp515063D metal printing is another possible route to 'castings' of very high quality – perhaps requiring minimal finish machining of sliding surfaces.

Whilst laser or electron beam systems are still very expensive, extrusion based systems are significantly cheaper and give pretty good accuracy, if not quite as flexible regarding final part geometry.

All the different options have pros and cons. There is no single 'one size fits all' approach.

19 January 2022 at 16:15 #581223HOWARDT

Participant@howardtI am of the opinion that castings for this hobby will become less affordable. As years go ny there are less of us so buying less, and the only way the prices can be kept down is volume sales and the equivalent production. Without the sales they cannot cast in volume as it just becomes expensive door stops.

At the moment I am building a Super Simplex. Cylinder assemblies and all the wheels have been manually machined from solid Ci bar. Much cheaper to buy bar than castings, alright there is more machining to be done but once you think of the process it is not too bad and forget the little imperfections (cock ups) after all it is a running model not an exhibition piece.

As has been said there used to ge foundries in most towns supporting the local industries. In my early design days I used to work with four foundries locally, ferrous and non. They all went to the wall with the introduction of health and safety requirements for clean air, non could afford a million pound investment, probably the early nineties. The place I was working at moved over to fabrication and machine from solid instead of castings. It was cheaper to machine on the big cnc mill than wait for six months for a casting. At one time the factory had its own pattern shop, probably with half a dozen pattern makers, all of whom got made redundant at the same time.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › General Questions › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Even the Dealer Didn’t Know!

Started by:

Chris Crew in: The Tea Room

- 8

- 8

-

18 July 2025 at 01:09

howardb

-

What Did You Do Today 2025

1

2

…

7

8

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 33

- 184

-

18 July 2025 at 00:43

Nigel Graham 2

-

Model Engine running just off a naked flame

Started by:

Blue Heeler

in: Stationary engines

Blue Heeler

in: Stationary engines

- 1

- 1

-

18 July 2025 at 00:37

Blue Heeler

Blue Heeler

-

Measuring a double Vee lathe bed Vee position

Started by:

Kim Garnett in: General Questions

- 11

- 20

-

17 July 2025 at 22:24

Kim Garnett

-

Backplate studs

Started by:

Dalboy in: General Questions

- 3

- 4

-

17 July 2025 at 21:42

Dalboy

-

Herbert B drill information?

Started by:

Andrew Tinsley in: Workshop Tools and Tooling

- 4

- 9

-

17 July 2025 at 21:00

gerry madden

-

Ti-6Al-4V

Started by:

Vic

in: The Tea Room

Vic

in: The Tea Room

- 2

- 2

-

17 July 2025 at 20:59

old mart

-

Model Engineer Magazine Collection

Started by:

mfengine1 in: Books

- 8

- 11

-

17 July 2025 at 18:19

John MC

-

“swedish iron”

Started by:

moonman in: Materials

- 16

- 22

-

17 July 2025 at 15:35

John Abson

-

Multi Cylinder Radial Engine.

Started by:

ebeneezer in: I/C Engines

- 5

- 7

-

17 July 2025 at 14:34

duncan webster 1

-

motor and switch wiring Myford ML7

Started by:

1957jmh in: Workshop Tools and Tooling

- 7

- 13

-

17 July 2025 at 14:22

1957jmh

-

TurboCAD – Alibre File Transfers.

1

2

3

Started by:

Nigel Graham 2 in: CAD – Technical drawing & design

- 12

- 54

-

17 July 2025 at 12:21

Nigel Graham 2

-

Silver steel crankshaft

1

2

Started by:

teamricky in: Stationary engines

- 11

- 38

-

17 July 2025 at 11:49

cogdobbler

-

Chucking Money Away!

Started by:

Chris Crew in: The Tea Room

- 6

- 9

-

17 July 2025 at 11:33

Chris Crew

-

Soldering to gold plating

Started by:

Stephen Harris 5 in: General Questions

- 10

- 16

-

17 July 2025 at 10:38

Michael Gilligan

Michael Gilligan

-

Advice to machine stationary engine base plate

Started by:

Greg H in: General Questions

- 5

- 9

-

17 July 2025 at 07:23

JasonB

JasonB

-

Drawings for constructing a Rolling Road

Started by:

Greensands in: Help and Assistance! (Offered or Wanted)

- 8

- 11

-

16 July 2025 at 21:12

ChrisLH

-

How many spokes do I really need?

Started by:

Fulmen

in: Related Hobbies including Vehicle Restoration

Fulmen

in: Related Hobbies including Vehicle Restoration

- 7

- 19

-

16 July 2025 at 17:13

Fulmen

Fulmen

-

Boiler Design – issue 4765

1

2

…

8

9

Started by:

Charles Lamont in: Model Engineer & Workshop

- 27

- 212

-

16 July 2025 at 17:04

Paul Kemp

-

Electronic leadscrew pitching error

Started by:

paulg 1

in: Introduce Yourself – New members start here!

paulg 1

in: Introduce Yourself – New members start here!

- 4

- 21

-

16 July 2025 at 12:19

JasonB

JasonB

-

I’m Under Pressure

1

2

Started by:

howardb in: Related Hobbies including Vehicle Restoration

- 18

- 35

-

16 July 2025 at 10:21

Michael Gilligan

Michael Gilligan

-

Suds tray sealant

Started by:

Dave S in: General Questions

- 7

- 7

-

16 July 2025 at 01:31

cogdobbler

-

Error-Message of the day

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 8

- 14

-

15 July 2025 at 20:42

Robert Atkinson 2

Robert Atkinson 2

-

Sat nag

1

2

Started by:

duncan webster 1 in: The Tea Room

- 23

- 45

-

15 July 2025 at 20:02

Andy Stopford

-

Farm Boy

1

2

…

4

5

Started by:

Dalboy in: I/C Engines

- 15

- 106

-

15 July 2025 at 19:52

Dalboy

-

Even the Dealer Didn’t Know!

-