Tailstock adjustment

This is what my tailstock looks like

The M5 bolt you see is not original. The original design requires that you pretty much have to take the tailstock off to tighten it up once you've got it set up. Needless to say, this is an excellent way of knocking it out of adjustment.

The basic approach is to leave the tailstock lightly tightened to the base and tappy tap until it's spot on then tighten it up. My skills with tappy tap seem restricted and getting the adjustment within .05mm is about as good as I can manage. Most often tightening the bolt slips it that far out again if with access from the top.

In the rear there are two grub screws which adjust the alignment. I'm not entirely sure how they are supposed to work since they are bearing on to flat surfaces. They do a bit. However, even with the nearer screw tightened pretty hard the tail stock is still at an angle (towards me as it moves from the tailstock along the barrel. I suspect that adjusting with this tight isn't really helping the ease of adjustment.

So what to do?

I've seen some designs for forward and back tailstock adjusters (e.g. this)- basically a bracket and a stud thread. It would have to go at the back of the tailstock since it will get in the way of the carriage and slides if it were at the front.

My concern with making that is tapping cast iron. when I fixed my lathe I put some grease nipples in the headstock (M6) but had to redrill and tap to M8 because the thread stripped the first time I tried to take the grease gun off.

I expect I will want to use M5 fine for the bolt, so one turn is 0.5mm, (.01mm is 7 degrees – well beyond my aspirations!), however I suspect this is a bit fine for cast iron.

The other question I have is how to get the thread tight in the not so there is little backlash. My tap and die set is pretty poor quality being an anonymous set I picked up years ago. even tapping aluminium has made the M6 tap unusable (and the M5 die has been destroyed tapping the bar that turned my last between centres attempt)!

I'd also appreciate any advice on the angular adjustment. I suspect that adding a jib strip would help, but I think I need to do something more if I want to get the angular adjustment spot on.

All help, pointers and advice gratefully received!

Iain

Iain Downs.

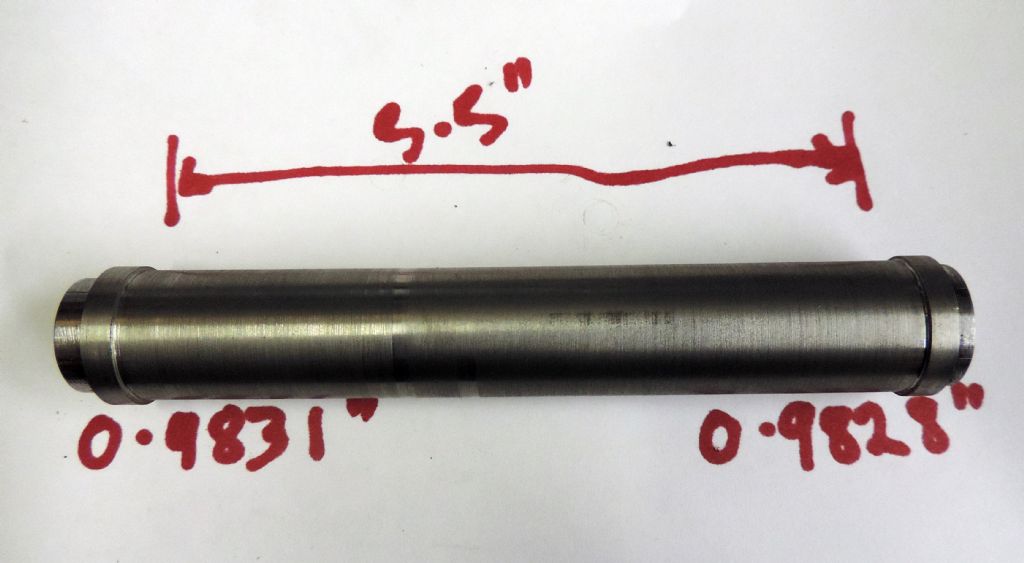

and a couple of thou out horizontally which is about as good as I can get without building a screw based adjuster (I've already brought the lock bolt up through the top of the tailstock base as having it underneath is just ridiculous).

and a couple of thou out horizontally which is about as good as I can get without building a screw based adjuster (I've already brought the lock bolt up through the top of the tailstock base as having it underneath is just ridiculous).