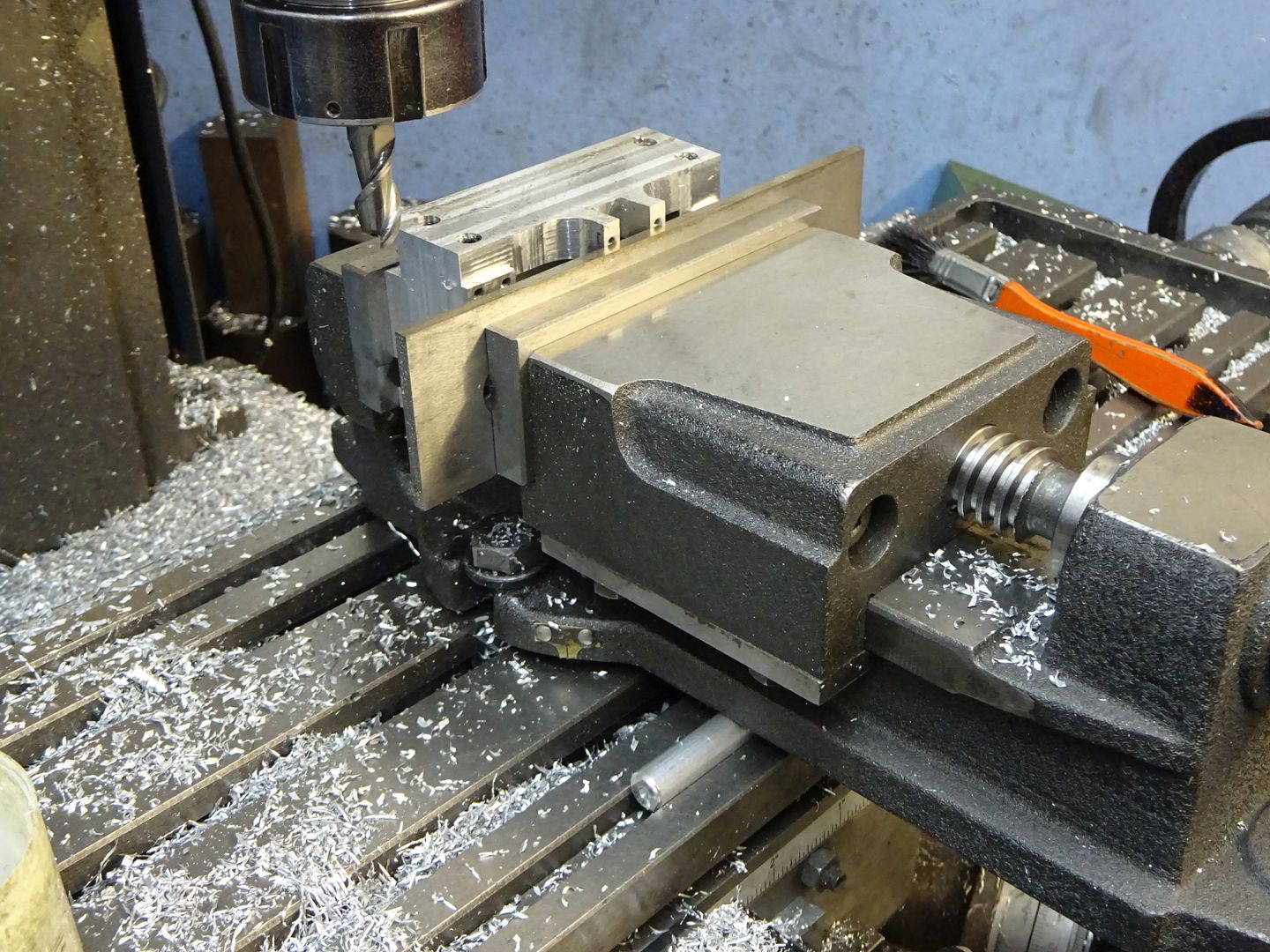

So this morning I had a play about with fly-cutting some scrap aluminium.

I used Jason's vice tilt method, which worked well, but I think a longer workpiece will definitely need more support – somehow:

I had to grind the back of my toolholder (under the insert) a bit, because it was scraping on the workpiece.

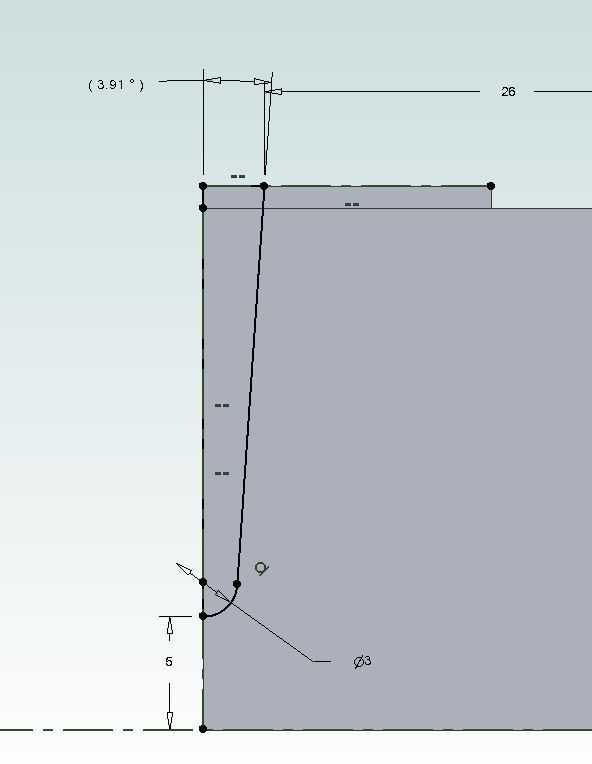

This was just a random angle, I think it looks OK, perhaps bit shallow. I used to design steel castings for offshore oil platform jackets, and it was always about a 3 degree taper for those.

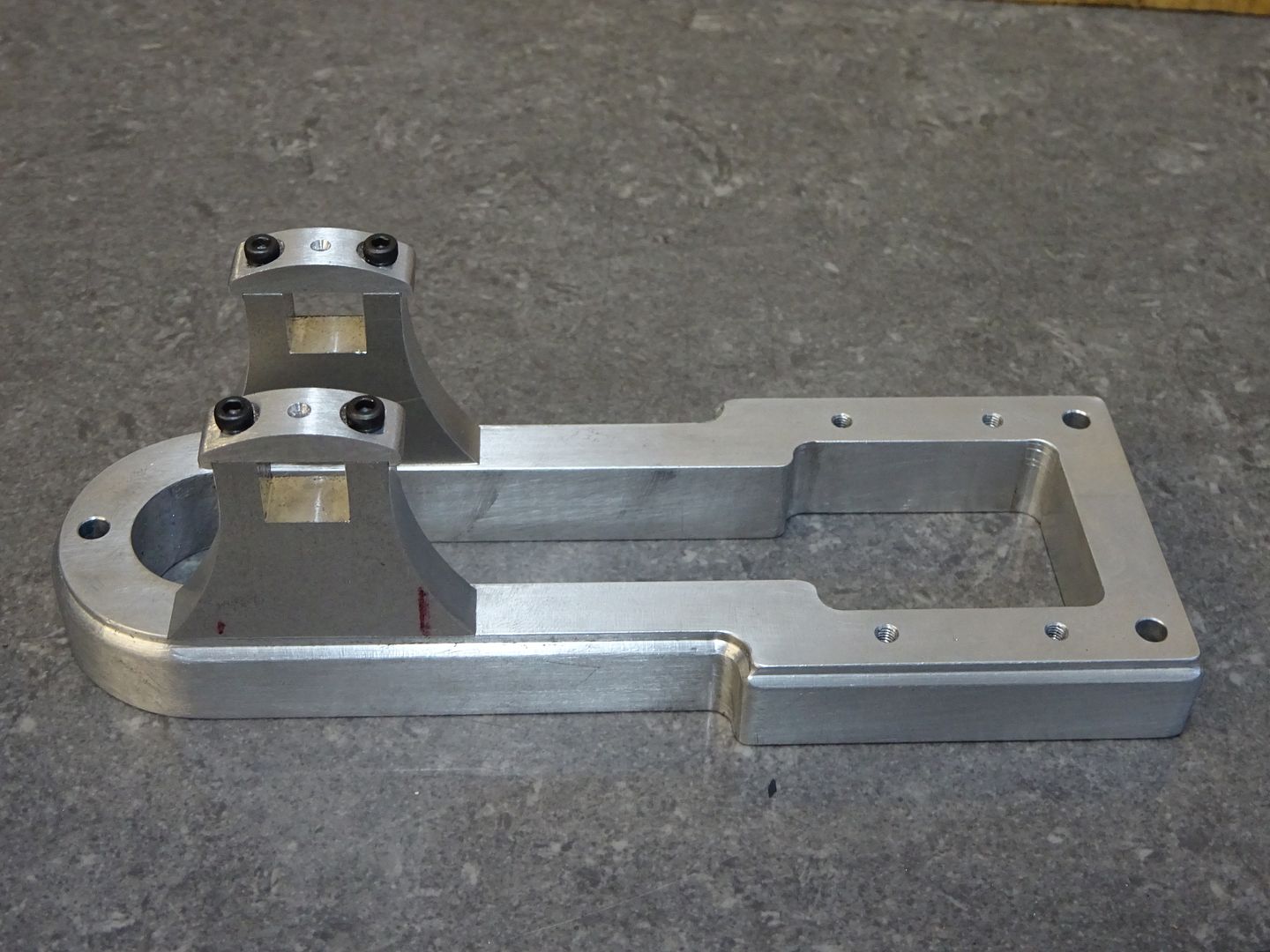

Here it is de-burred and after a light going over with wet and dry:

And painted with primer:

I think the finish is fine – I was pleasantly surprised with how it machined since I only have 0.8mm radii inserts for cast iron and steel.

It's going to take some very careful setup and marking out once I've figured out a holding method, but at least I know it's doable from my point of view.

Regarding the taper on the ends: I guess I could assemble the whole lot with machined sides and plain ends, then clamp down with the opposite end raised slightly to give the draw angle, then mill the sides vertically? This would give a fairly stiff structure for machining, and I could mill the ends of the long sides and the ends faces simultaneusly, guaranteeing they match. Then again I'm still really struggling with chatter with side milling, even on aluminium.

The "start next year" idea seems to have gone out of the window. As with my scale modelling projects, I always tell myself I'll take a break and just enjoy the completed stuff I've done, but for some reason the allure of next project is always irresistable.

Dr_GMJN.