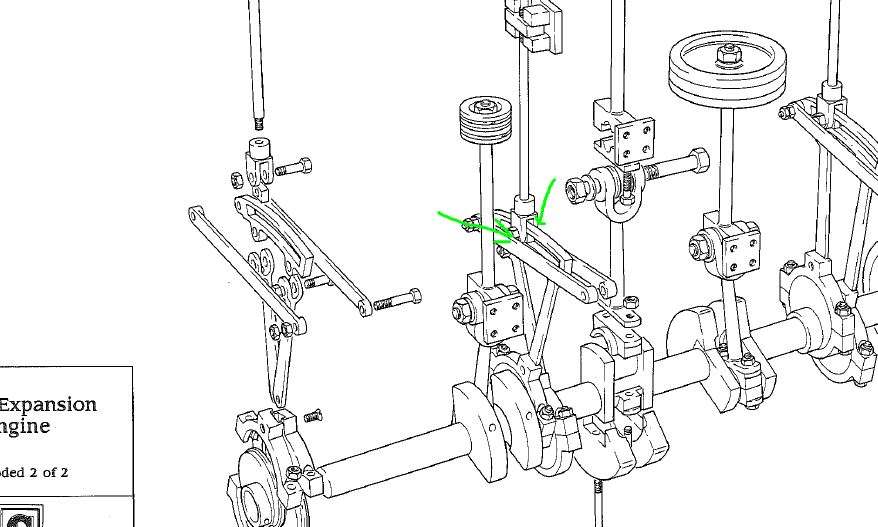

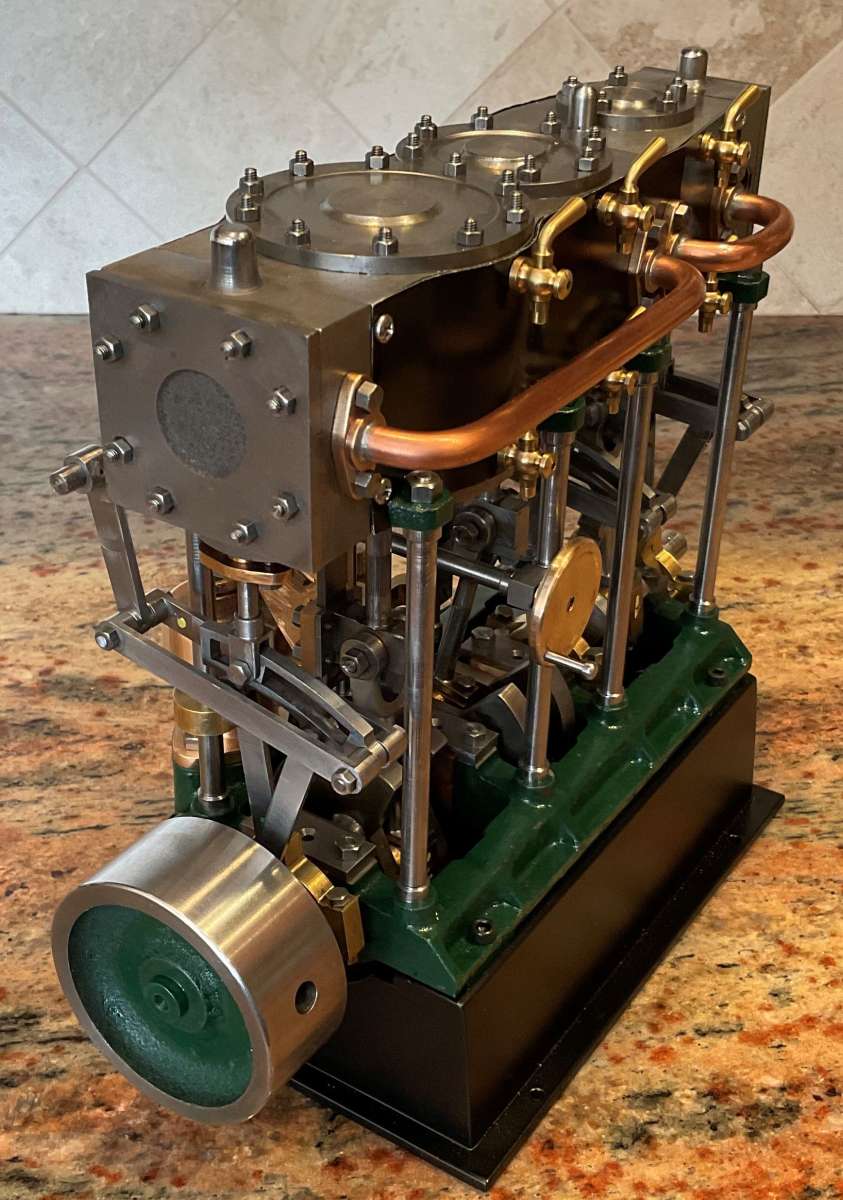

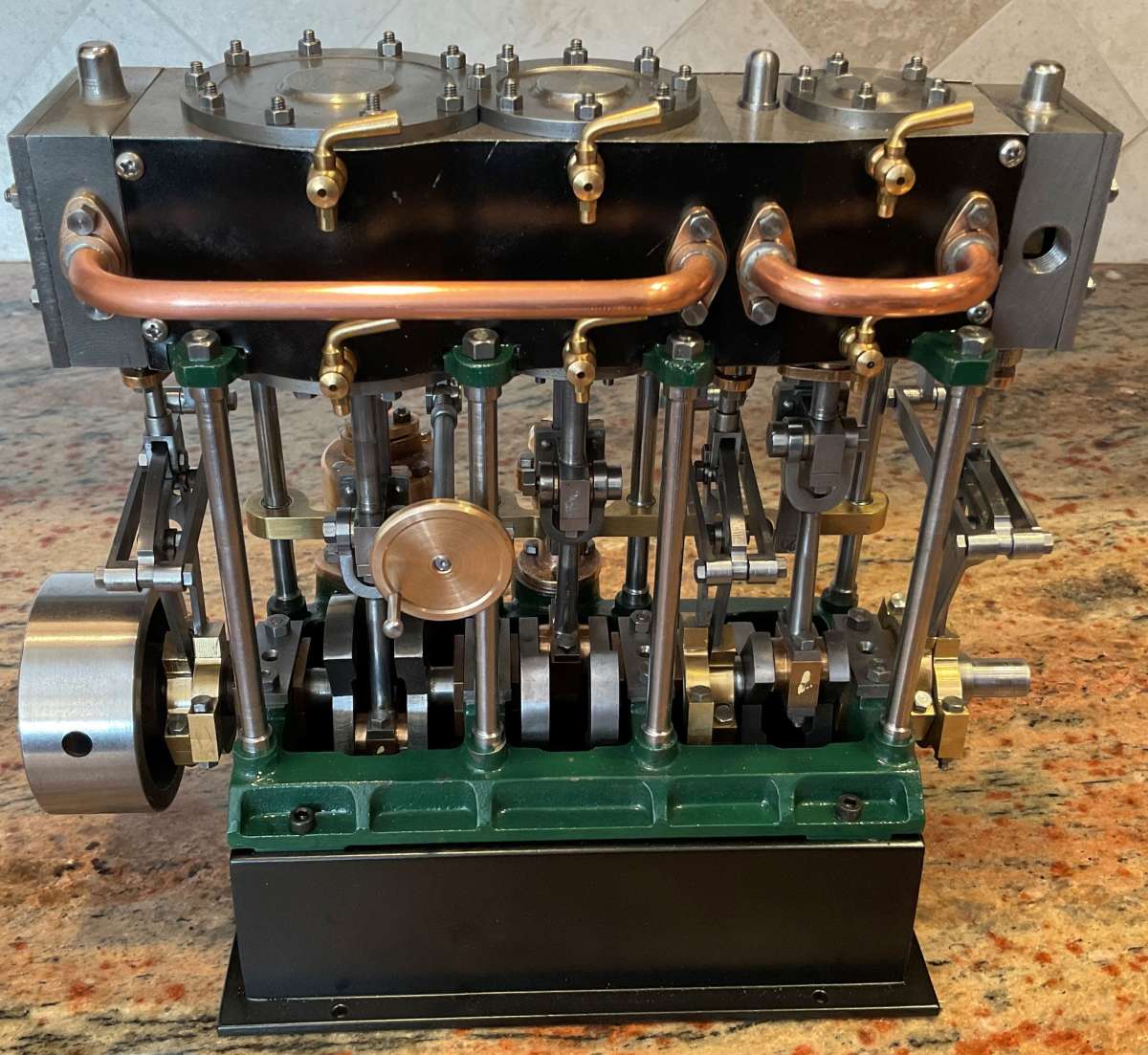

I’m in the close to final assembly stages of my Stuart triple build, and have hit a snag I haven’t been able to figure out. I’m going to use the component terms supplied by Stuart as I attempt to explain my conundrum.

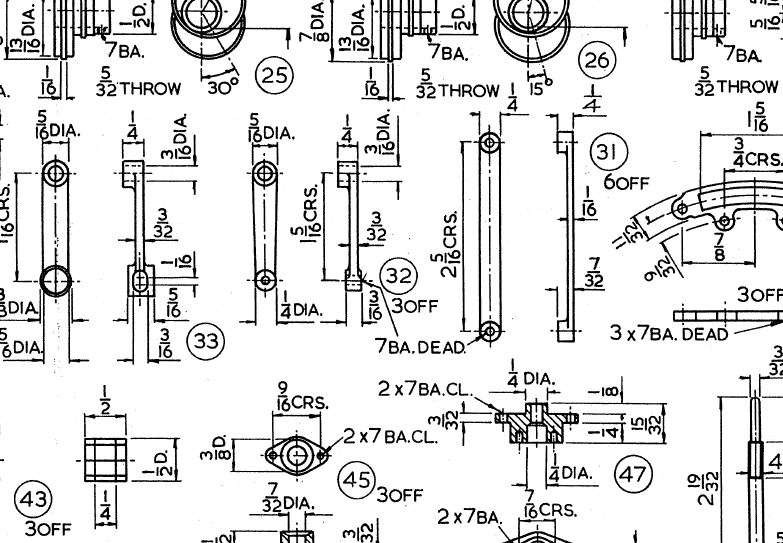

When the drag links are assembled, they cannot pass the little 7BA fastener that holds the steam chest valve rod to the reversing eccentric..they need to be spread out more, for lack of a better explanation. The parts are build to the drawing, but there is absolutely no way that I can see it would work without either making new drag links with thicker offsets on the ends, or making small spacers to space the drag links apart so they won’t contact the cross-head bolt that goes through the eccentric.

I’ve looked at a bunch of pictures, have watched Keith Appleton’s videos and I see nothing obvious other than the drag links in those pictures have thicker spacers on them. My print sheet calls out one end at 3/16″ thick and the other end at 5/32″. The item I’m blabbing about is #31 on my print sheet, which is dated 1981.

Thanks,

Stuart Miller

Eureka, CA USA

atomarc.