First posting and upload of photographs, so I hope this goes ok!

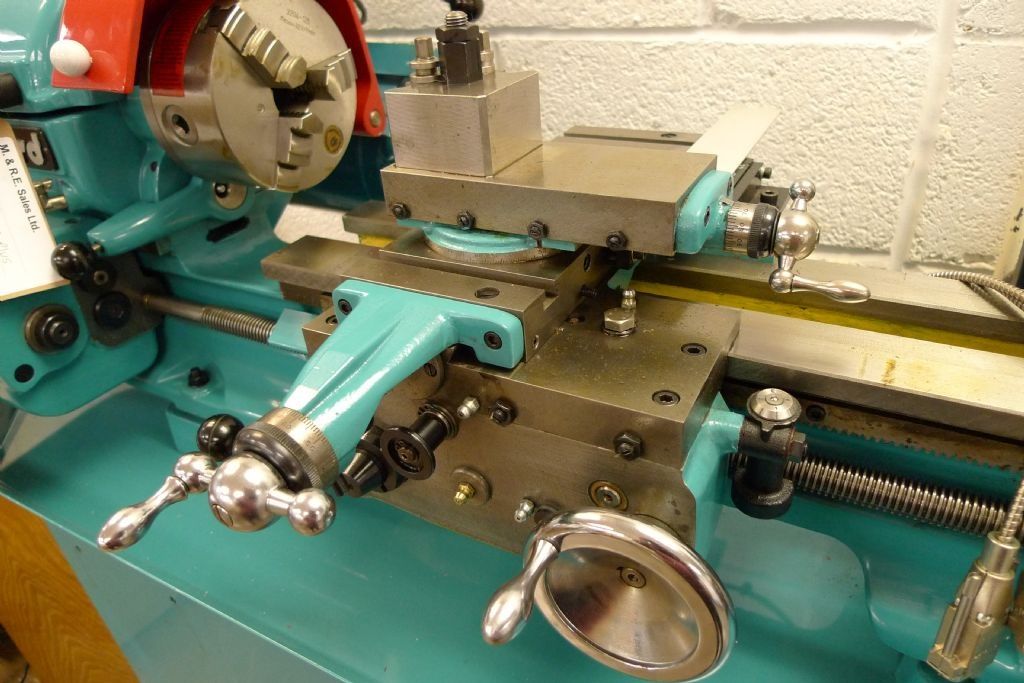

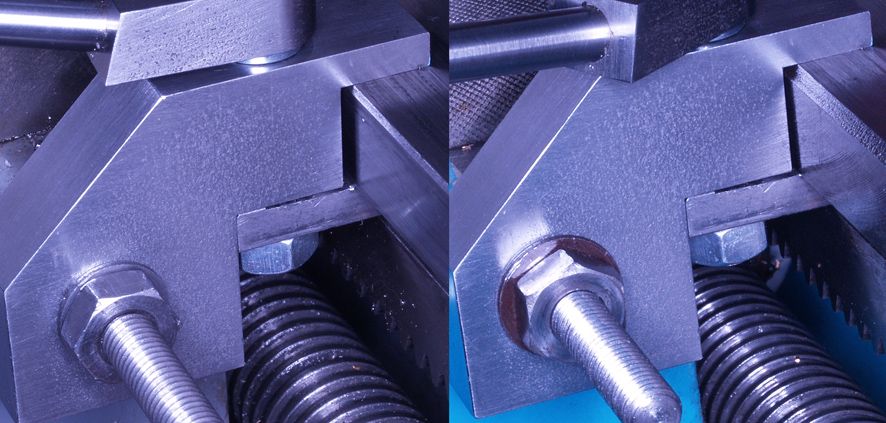

Peter: some photos uploaded to an album. Yes, the plate is mounted via the TT attachment holes in the bed.

These are actually photos of the first Newall Microsyn installation onto an S7, about which I wrote an article or two which were published in MEW about 2002 – give or take a year! Since then I’ve found it to be perfectly satisfactory, and I’m about to repeat the installation on another machine. Newall must also think it satisfactory, since they’ve based their design for their S7 installation kit on it, albeit with the reading head mounted lower, by virtue of it being vertically oriented as opposed to horizontally in my design!

KWIL’s installation appears to be on similar lines, but with some differences, one of which is worth pointing out.

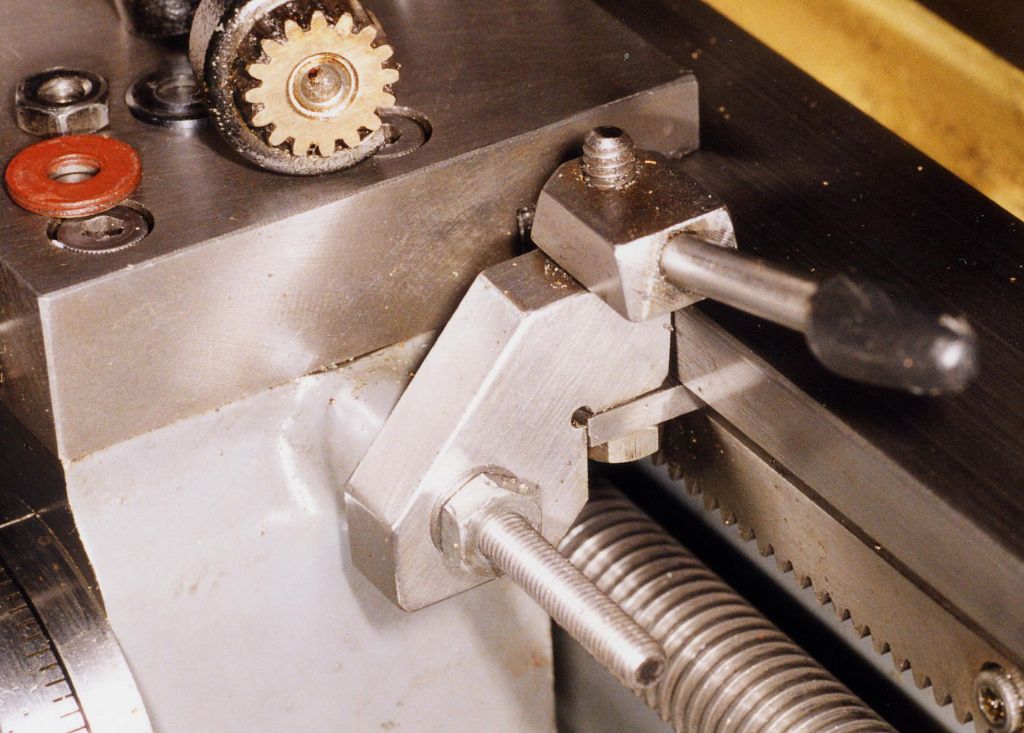

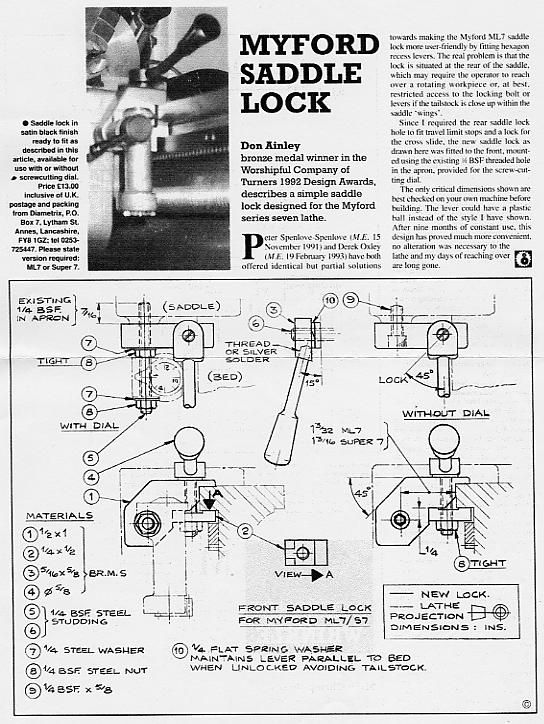

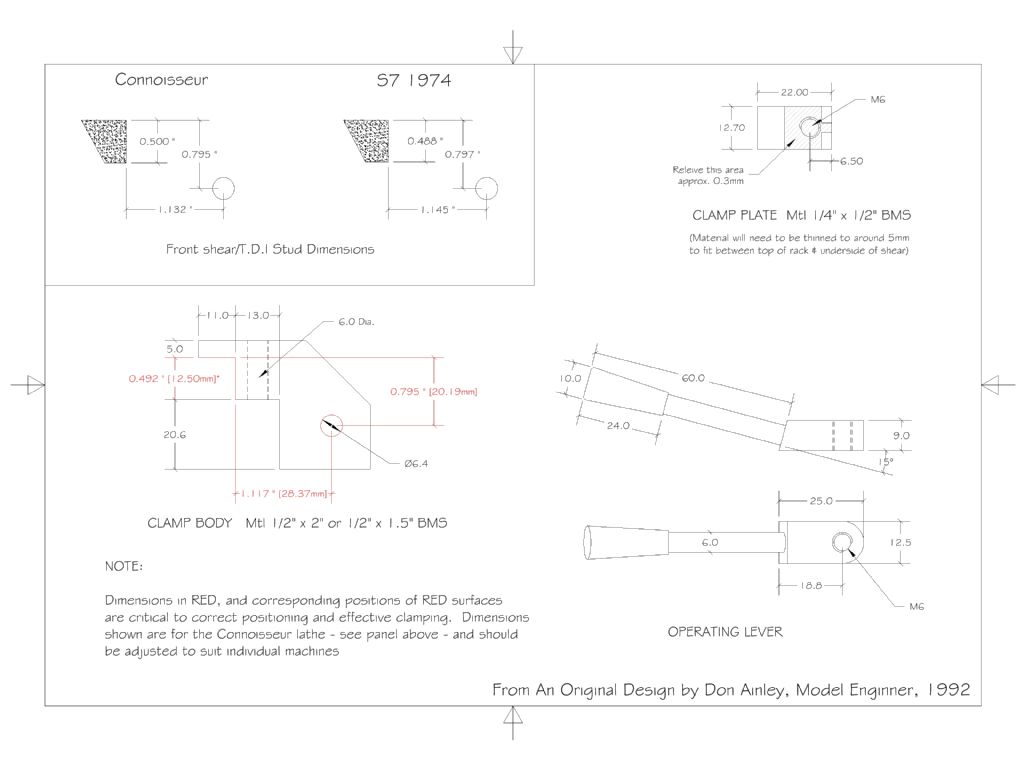

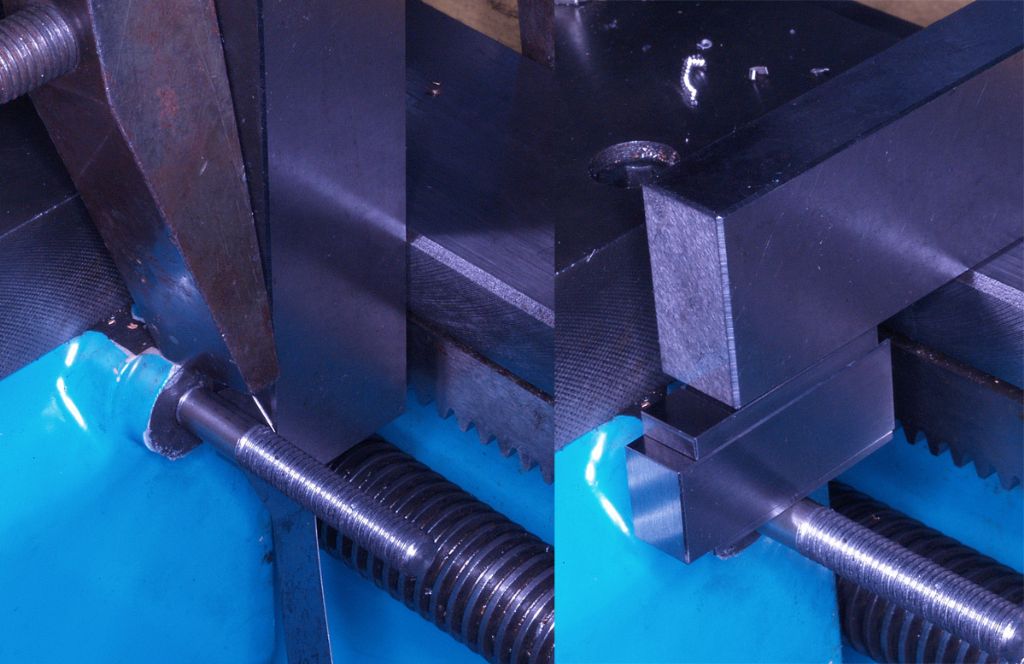

I leave the taper attachment permanently installed – fitting and aligning one of these things is best done only once! The pin on the attachment slide is therefore a permanent feature, but it has to be low enough to allow the crosslide DRO scale to clear it. Which in turn means that to use the attachment it is necessary to make an extension pin that attaches to the original one.

My original extension was in the form of a very close fitting sleeve that slipped over the original pin. Inevitably there must be some small clearance and that allows the extension to tip slightly when the saddle moves one way, and tip in the opposite direction when going the other way – which introduces what can best be described as backlash in the taper cutting path.

KWIL’s unit seems to be mounted somewhat lower than mine, so the tipping/backlash effect will be greater. I suggest that you consider mounting the attachment as high as possible, as per my original drawings in MEW. If you want those drawings I can send them to you direct as .pdf files.

Rather than use a sleeve attachment, it’s much better to us a clamping system to extend the extension pin – I don’t have any photographs of this, but I do have a drawing, so I can send that as well. The pin on this extension arm is a replica of the bit that attaches to the cross slide bracket, so it gives a direct connection between the saddle and the taper turning slide, no backlash there. But even with that it’s still advisable to mount the TT attachment as high as possible to minimise twist loadings on the ways and gib of the TT slide.

Oh, a very important point here – if you do use a direct, clamped, connection, the TT atachment must be PERFECTLY level with the top of the bed, or the TT attachement will try to push the saddle up or down – which is, I suspect, why the Myford original pin is a sleeve/sliding fit, to allow it to move up and down a bit if the attachment is not in perfect alignment with the shears. If you’re not confident about getting this set up spot-on right, stick to the sleeve arrangement, making it a good a fit on the original pin as you can. And mounting the attachment as high as possible, of course!

With a low-backlash connection (only the original slide ways and gibs contribute now) setting tapers becomes very easy using the DRO – just zero both axes, then move the saddle one way for say 3″, and adjust the TT slide until the cross slide reading shows that you have the required movement to produce the taper.

Martin King 2.