Posted by Dave Halford on 27/06/2020 12:34:08:

You need to decide how much un-bent ring you can live with.

Pyramid rolls where the top middle roller drives and bends the metal by pressing it down between 2 fixed rollers leaves a flatish start section. The top roller (which needs to be removable) gives the minimum ring dia

Initial pinch where the metal is clamped between 2 rolls and drives the metal, the third roll moves past their centre to give the bend. The top pinch roller (which needs to be removable) gives the minimum ring dia. This one will roll a true round assuming you cut the length correct and grips the metal better and so slips less.

You can make rings on a sheet roller.

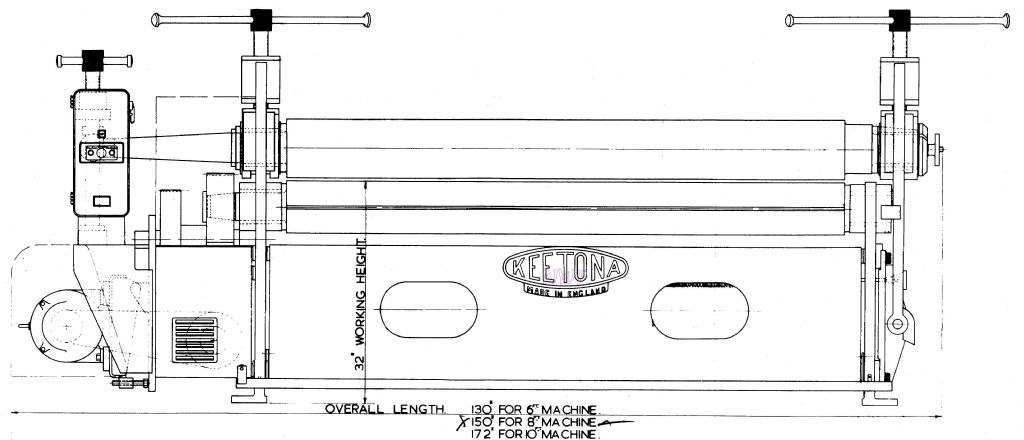

Hi, you'll get a flat section on both ends with pyramid rolls. Although for small rolls that may be used in the home workshop, the top roll is probably easier to make totally removeable, but both types of rolls can have just one end bearing removable so the rolled piece can be slide out, all industrial rolls I've used large and small work this way. In the drawing below it shows the weight of the top roll is taken at the left hand end by a turn screw, the right hand end will pivot down after the wing nut and plate is removed from that end of the roll.

I've only ever used 3" pinch rolls and these often have a handle that you can hold up when removing rolled piece. Of course if you are only doing a part roll or if the metal is flexible enough you won't need to remove anything.

I've always found pyramid much easier to use on thicker plate as they generally have more power and you can get over the flat bits at the ends by using a long enough piece for them to be cut off and then you only have one weld and normally in general fabrication this would have the weld dressed down flush and the cylinder return back to the rolls using extra pressure to slightly over roll and thus the spring-back will produce a close true circle.

Regards Nick.

Nicholas Farr.

Nicholas Farr.