Martin,

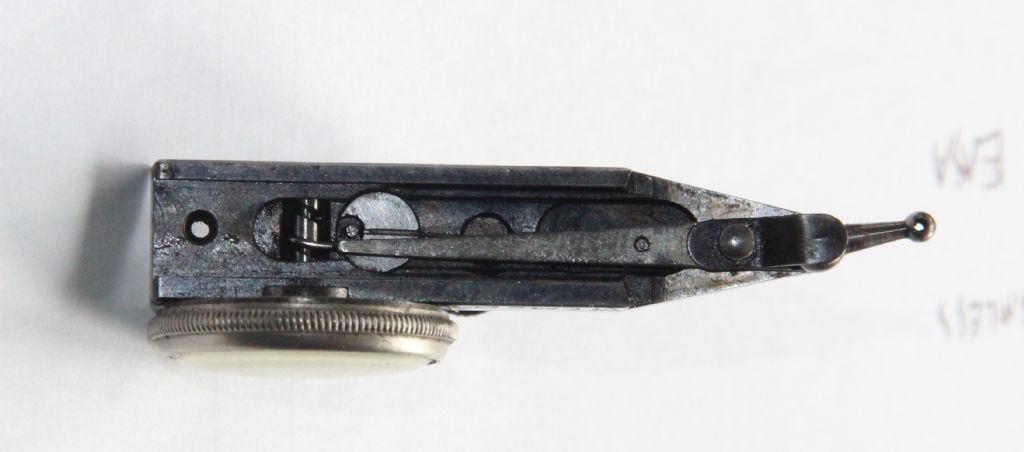

To me, your verdict is not just elderly, it's very elderly/old and nothing like the pictures posted. Does it say Verdict on the dial or are you just referring to it as a Verdict type? Go back to my first post and consider that the dial pointer only travels just over one full turn. Move the lever under the dial to each extreme and you should find that the dial pointer reverses its action by one turn. The probe then works the dial in the other direction. It is not a centre-zero device. Rotate the dial's bezel to reset to read zero if required. If you do have a fault the spring wire (your "hair spring" description I think) on the inside end of the external lever looks bent in your top picture.

Mick,

I have no idea how old my Verdicts are; they came to me with a Myford years ago. I would assume that a plastic lever would represent a more recent 'improvement' as they say. I have three of them, all in their blue boxes with fittings but I only ever use one of them and there are multiple variations of the included fittings The two unused ones have one inch diam dials and 0.01mm and 0.001" ranges. The inches one sports an extended probe (by me) to the original, 20mm long instead of the original 10mm that I made when I needed longer reach, not considering the loss of sensitivity as a result. Just a means to a tricky end. Incidentally I have two spanners to fit the flats on the probes included in the boxes so some gauges probably came with multiple probes with different lengths and/or tips.

The DTI I do use has a 1.5" dial and 0.0005" scale which totally beats the other two, I normally use a dial gauge through choice and never measure with any of them.

Dennis

Clive Brown 1.