A few points relating to some of the posts above:

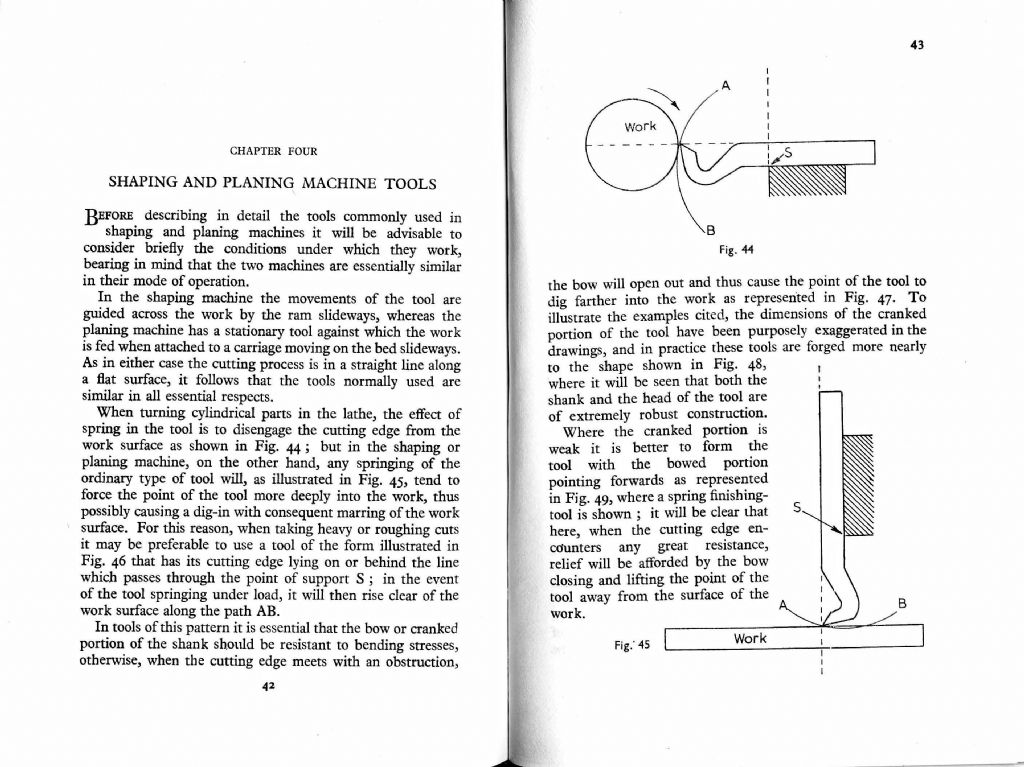

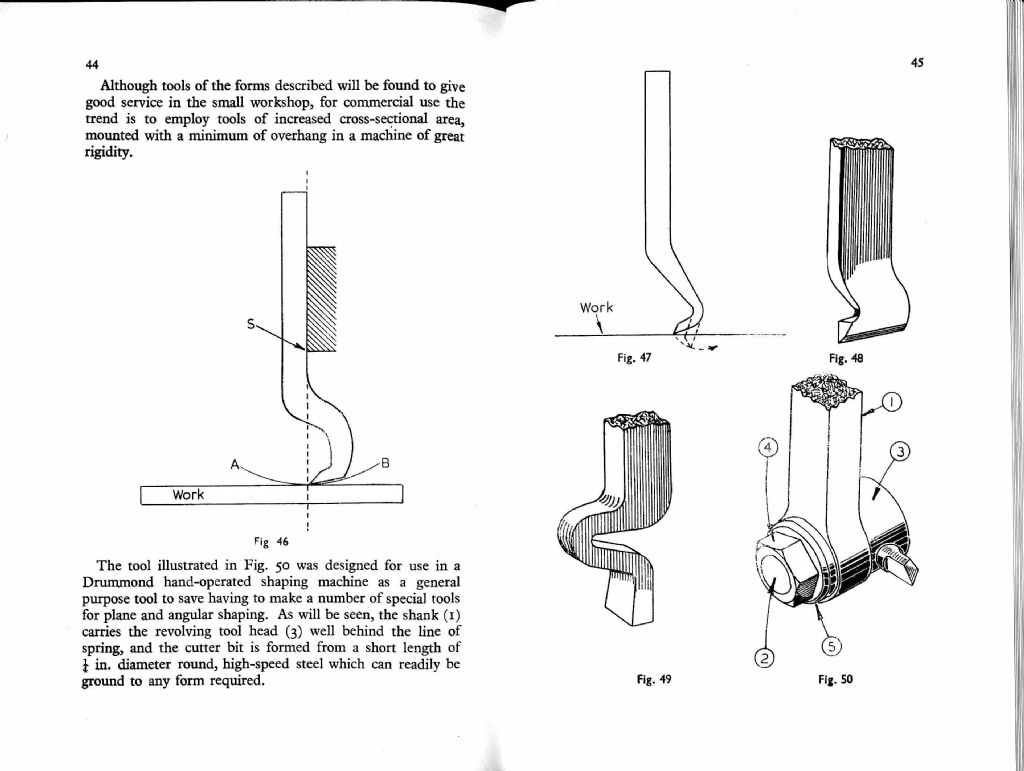

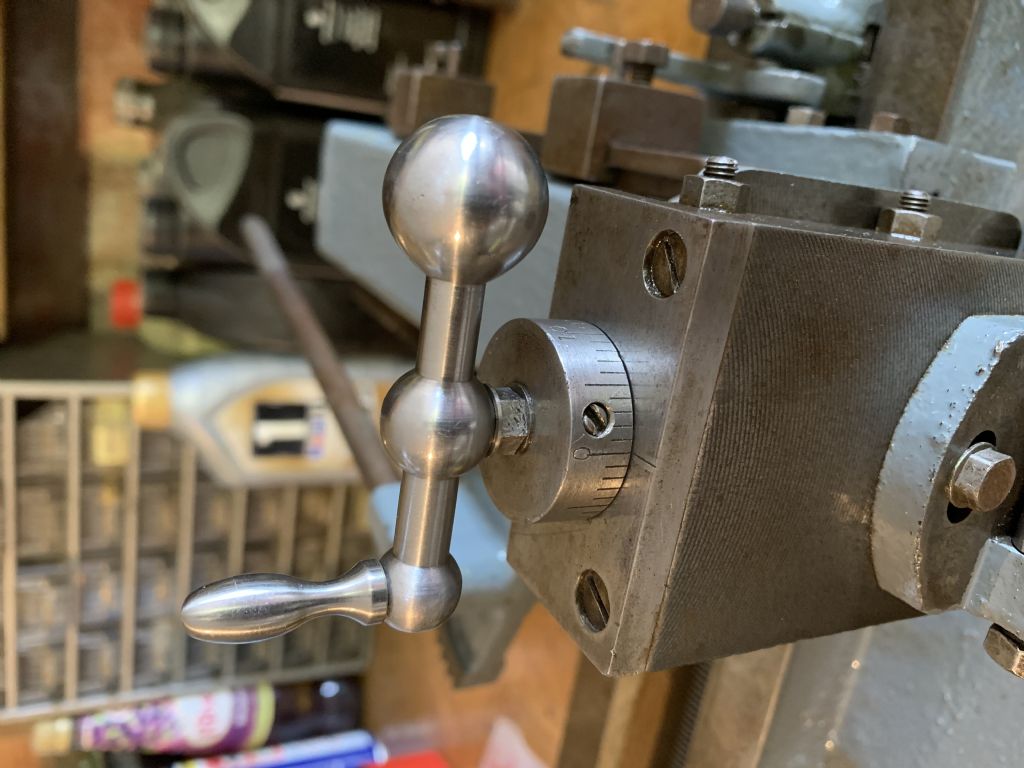

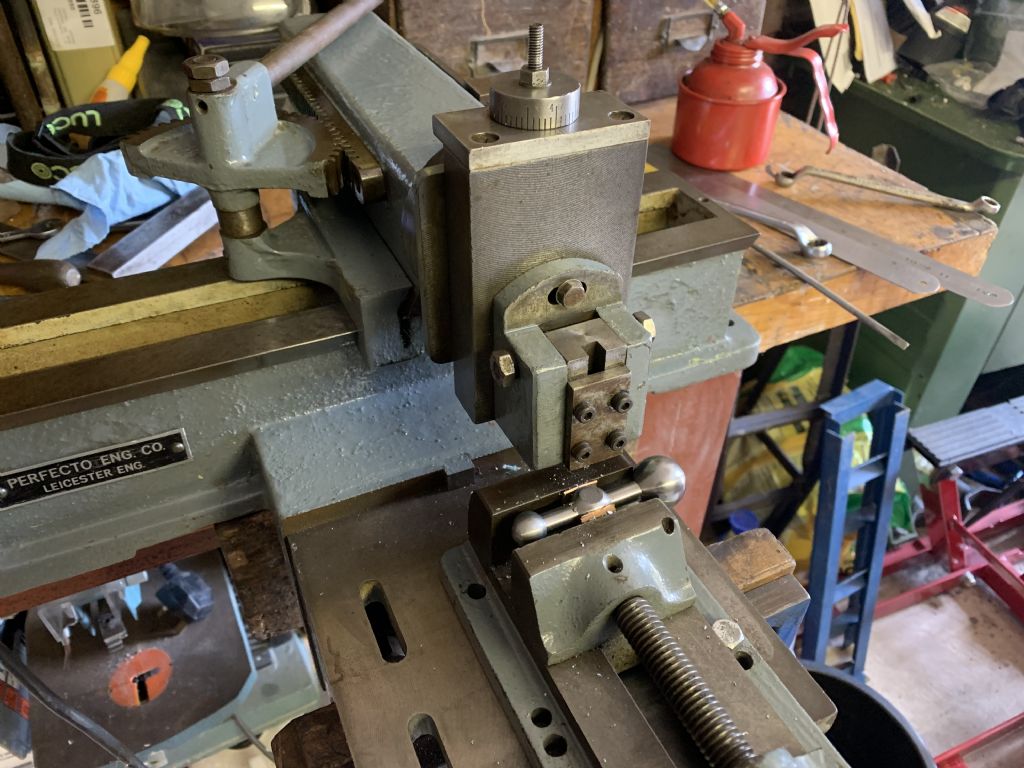

Assuming the clapper box pivot does not have too much slack, the only flex we need to worry about is the projecting part of the tool. In theory, when this bends with the cutting load, it can tend to make the cut deeper. In practice, this does not seem to be a big problem. Keeping your tools really sharp will greatly reduce the cutting load, which will also reduce the effort needed on a manual shaper. I have played with tool holders that put the cutting edge about level with the clamping face of the clapper box, but it does not seem to make a great deal of difference. I've also got a pair of toolholders that were made for a lathe with one of my shapers, they have built in rake, which is all wrong for a shaper but actually works fine in practice.

I have used a goose necked tool, my first shaper came with one, since sadly broken when it fell on the floor. Again, it did not seem to give better results than a conventional straight tool, and actually the geometry would seem to permit more flex in the digging in direction.

If you are cutting on the return stroke with a power shaper, you should ideally reverse the direction of the motor. If it is not easy to do, I would not worry too much, especially if the stroke is short.

There are possible cuts where you might need to lock the clapper box, although mostly you can get the clearance by angling the clapper box. For instance, when cutting a dovetail, the downslide will be angled to the angle of the dovetail, and the clapper box should then be angled a little more, so that when the tool moves it comes away from the overhung face being cut.

regards

John

ega.