Muzzer – stood with a thick Perspex sheet in front of me with one hand and the other hand on the emergency stop, It did scare me so I haven't run it that fast since.

Dave – The taper is 1:19.2307. I started the big end a mill above the nose bore and tapered down a mill below the bore. So the big end was 39.2mm tapering down to 34mm at a length of 100mm (39.2 – (100/19.2307). I admit I'm not happy with how little contact area there is in the nose, not sure what the Colchester is like, but the Harrison M250 is only 15mm long, about a 30mm gap and then a little more of a taper.

Turns out I had a MT3 arbor for a drill chuck, has a M12 thread in back  .

.

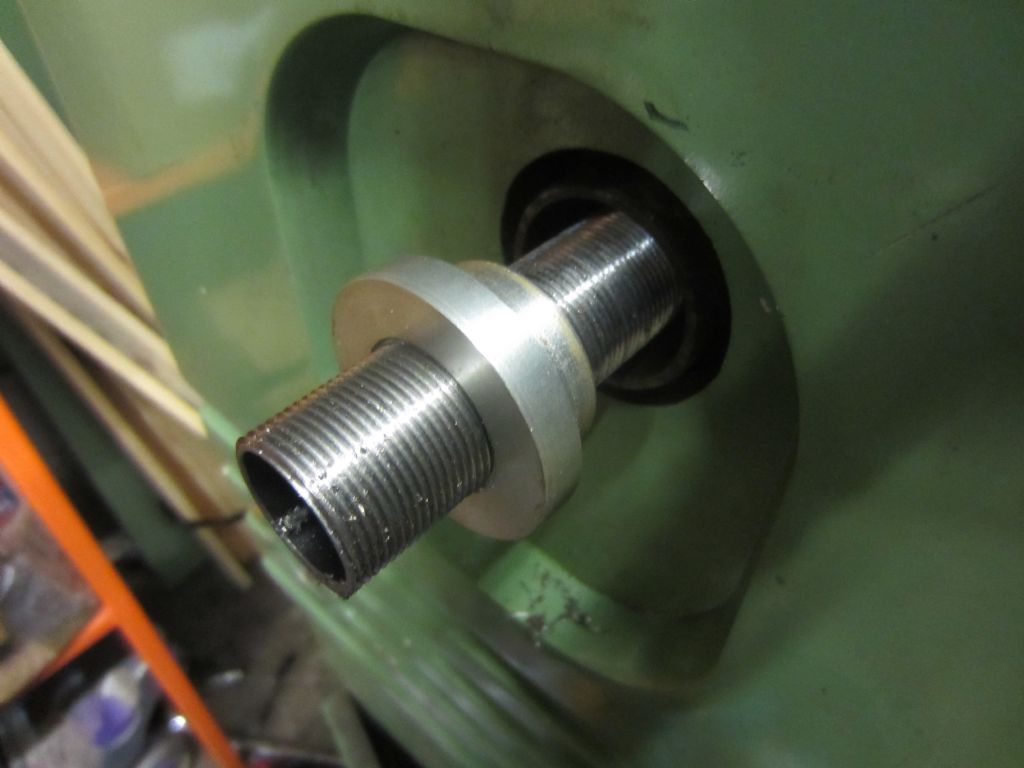

Anyway as for the adapter, made a nut for the draw bar from a top end timing pulley, magnesium alloy so it seems to have worked out ok because the threads aren't sticky, saved some time instead turning and milling a nut. Drilled out the adapter nose to 20mm as the smaller end of MT3 is 20mm, just to allow tung types to fit down it. Then bored it out using aluminium inserts and the final pass was 240rpm, 0.5mm at 20mm/min. The boring bar was only turning 90mm inside but had to stick it out 120mm due to the carriage hitting it's limit.

Overall I'm really happy the way it turned out, taper came out perfect and no mistakes, yeay. Piccy's:-

Joe Page.