Both Norman and Bazyle have valid points but my suggestion is learn the ropes first.

Small mill ie sub 14" table I wouldn't bother with a power feed unless can alter and adapt a suitable motor. Larger mills its more a priority over DRO.

Most power feeds are on the fly where can instantly adjust the feed rate to suit application in 1 second or less, no gearboxes of old. Wouldn't recommend the left side hang off type you may need to drop long items where its in the way. Tradition is the right side feed since something like 95% are right handed. May need to adapt/lengthen leadscrew, make a bracket to suit machine with offset, buy conversion parts, power feed unit £300+ and transformer running 110V £50.

Vertical elevation packed on mine 4 years ago and dread unlocking gibs, winding up and locking gibs back down every time.

Various other functions can be done with a dro but not worth while. Used PCD once in 10 years no other function interests or is profitable for me to do by that method. No need to mark and punch hole positions just plough straight in, job done.

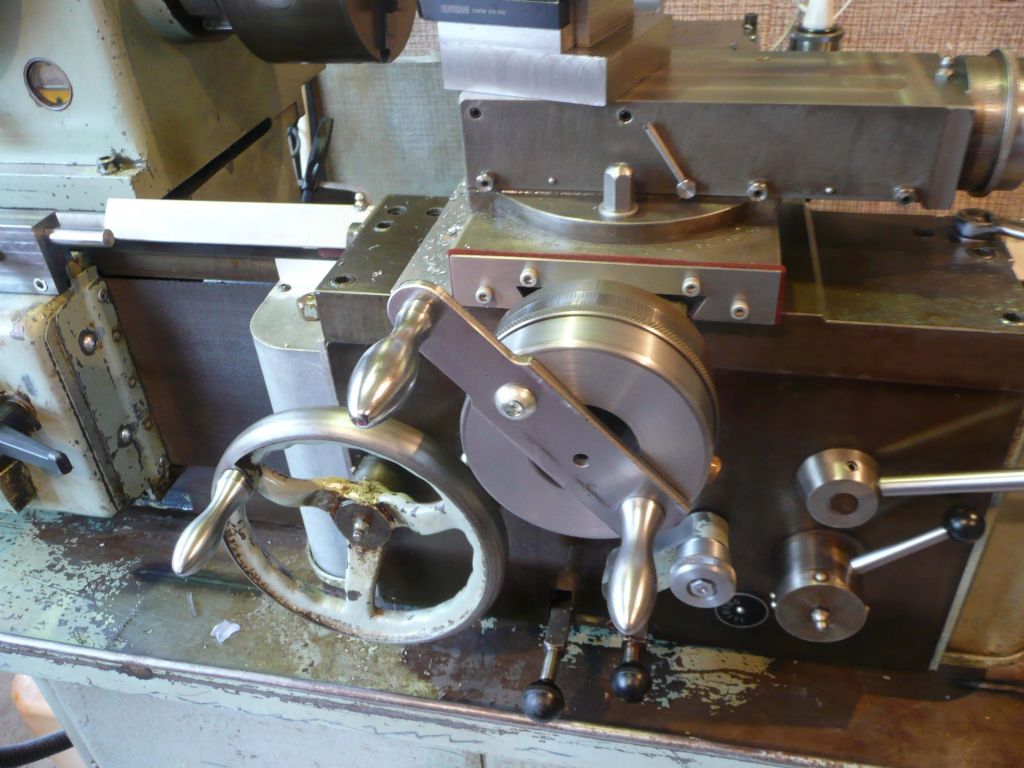

Dro on lathe can be more worth while, tool offsets for those that have more than one cutting tool, lengths X with crossfeed Y, equally as efficient is tailstock dro as a time saver. If write coordinates down its as good as any cnc with human error.

Clive India.