injector problems still

injector problems still

Home › Forums › Locomotives › injector problems still

- This topic has 83 replies, 19 voices, and was last updated 10 June 2017 at 20:15 by

Werner Schleidt.

-

AuthorPosts

-

2 March 2017 at 16:31 #286760

Ron Hancock

Participant@ronhancock63652i ordered a d bit and will make my own seats with new Balls.

Hi I think now I could make my own Clack Valves but after seeing how Julian had done them for me I still have 7 more that would not seal.

As for injectors they are a work of heart and you have to be very clever to make them.

Julian seems to just take them in his stride such a clever Model Engineer.

Wish he lived nearer so want to meet him I owe him so much.

I to think all clacks and injectors safety valves should be a legal obligation for main dealers to have them checked before sale.

Ron

2 March 2017 at 17:15 #286769Chris Gunn

Participant@chrisgunn36534I have just given my 4CD a pre steam test steaming, I had injector problems at the back end of last season, and upon inspection yesterday I found the clack valve body full to the brim with black sludge, and the ball stuck in the middle of it. I cleaned all that out, confident I had found and solved the problem, soaked the injector in malt vinegar overnight, reassembled it all and when I tried it today no joy at all. I had an even closer look at the injector, and took it apart, and found a slug of silicone sealant in the centre hole. Once that was removed it worked fine. I note that most soak their injector in white vinegar instead of malt vinegar, I imagine there is a reason perhaps someone could tell me what it is.

Thanks, Chris Gunn

2 March 2017 at 17:42 #286775 Neil WyattModerator@neilwyatt

Neil WyattModerator@neilwyatt> as a novice could not understand why i get the feeling they come from China sold very cheaply to supliers then sold at high profit where we become the frustrated loosers.

Ron, I don't think anyone in China is exporting boiler injectors to the UK, and it isn't fair to label anything that doesn't work as Chinese.

Let's face it, it IS possible for things that fail QC to be made in the UK and they should be returned for replacement or refund BEFORE a judgement is made on the supplier in any case.

Neil

2 March 2017 at 18:23 #286784Ron Hancock

Participant@ronhancock63652Posted by Chris Gunn on 02/03/2017 17:15:12:I have just given my 4CD a pre steam test steaming, I had injector problems at the back end of last season, and upon inspection yesterday I found the clack valve body full to the brim with black sludge, and the ball stuck in the middle of it. I cleaned all that out, confident I had found and solved the problem, soaked the injector in malt vinegar overnight, reassembled it all and when I tried it today no joy at all. I had an even closer look at the injector, and took it apart, and found a slug of silicone sealant in the centre hole. Once that was removed it worked fine. I note that most soak their injector in white vinegar instead of malt vinegar, I imagine there is a reason perhaps someone could tell me what it is.

Thanks, Chris Gunn

Mine had silver solder blob in also one cone was very loose.

Luckily Julian is making me a new cone don't know how so tiny.

Something I could never do my Loco has only Ran 4 times since finishing it injectors are all new so frustrating

Ron

2 March 2017 at 18:27 #286786Ron Hancock

Participant@ronhancock63652Posted by Neil Wyatt on 02/03/2017 17:42:13:> as a novice could not understand why i get the feeling they come from China sold very cheaply to supliers then sold at high profit where we become the frustrated loosers.

Ron, I don't think anyone in China is exporting boiler injectors to the UK, and it isn't fair to label anything that doesn't work as Chinese.

Let's face it, it IS possible for things that fail QC to be made in the UK and they should be returned for replacement or refund BEFORE a judgement is made on the supplier in any case.

Neil

One supplier told me they came in batches from China the problem is you buy them ready to fit but then it's months later before fitting and trying Neil.

I still think who ever sells them should test them.

Ron

2 March 2017 at 18:28 #286787Brian H

Participant@brianh50089Keep at it Ron, you've come too far to think of giving up. I imagine everone on here is rooting for you so, best of everything.

Brian

2 March 2017 at 18:31 #286789Ron Hancock

Participant@ronhancock63652Posted by Brian Hutchings on 02/03/2017 18:28:40:Keep at it Ron, you've come too far to think of giving up. I imagine everone on here is rooting for you so, best of everything.

Brian

Thank you Brian

Ron

2 March 2017 at 21:15 #286807SillyOldDuffer

Moderator@sillyolddufferThere's nothing new under the sun. Injectors feature rather often in old copies of Model Engineer. Mostly people having trouble getting them to function, occasional discussion about design, and in the 60's a row about about how they work at all.

However, it wasn't until today that I found that a faulty full-size injector had caused a serious accident. Wikipedia's account of the Ais Gill 1913 railcrash includes this:

"While the driver was out of the cab, the fireman was having difficulty getting an injector to work and the boiler water level was dropping. When the driver returned, both men worked on the injector, and eventually restarted it. While they were distracted by the problem, their train had passed all the signals at the Mallerstang signal box, which were at danger. The crew also missed a red lantern being waved from the signal box by the Mallerstang signalman, and another being waved by the guard of the first train. Shortly after, they looked up from their distractions to see the first train stalled in front of them only a few yards away, and far too late to stop."

Well done again Ron and Julian. It could have been much worse!

Dave

2 March 2017 at 21:24 #286808Ron Hancock

Participant@ronhancock63652Posted by SillyOldDuffer on 02/03/2017 21:15:37:There's nothing new under the sun. Injectors feature rather often in old copies of Model Engineer. Mostly people having trouble getting them to function, occasional discussion about design, and in the 60's a row about about how they work at all.

However, it wasn't until today that I found that a faulty full-size injector had caused a serious accident. Wikipedia's account of the Ais Gill 1913 railcrash includes this:

"While the driver was out of the cab, the fireman was having difficulty getting an injector to work and the boiler water level was dropping. When the driver returned, both men worked on the injector, and eventually restarted it. While they were distracted by the problem, their train had passed all the signals at the Mallerstang signal box, which were at danger. The crew also missed a red lantern being waved from the signal box by the Mallerstang signalman, and another being waved by the guard of the first train. Shortly after, they looked up from their distractions to see the first train stalled in front of them only a few yards away, and far too late to stop."

Well done again Ron and Julian. It could have been much worse!

Dave

Wow that's interesting thank you I wish my father was still here I remember him grumbling about injectors and the problems.

I think most was caused by drivers setting in different ways.

He worked for BR 42 years

Thank you Dave

2 March 2017 at 23:48 #286817julian atkins

Participant@julianatkins58923Hi Dave,

There is no excuse for a miniature injector not to work.

There is considerable other comment on the Ais Gill Disaster in more recent times due to the Midland engine having a new boiler with a higher boiler pressure that the original injectors were not designed for, and could not cope with.

So far as miniature injector design is concerned the details of manufacture and points to note are well documented. DAG Brown's book is the bible on such matters and is available by TEE publishing.

That many of the commercial examples now flogged by the trade do not comply with these fundamental principles is a matter of considerable concern.

My old very close friend and mentor Arthur Grimmett made over 3,000 injectors for Reeves and Kennions copying the Linden injectors. They were all tested before onward transmission to the retailers, and were 100% reliable. We are talking about the mid 1950s to 1983. John Cashmore made excellent commercial injectors as did Gordon Chiverton until a few years ago.

I have also heard rumours of Chinese products. When you have loose steam cones and delivery cones simply fall out of commercial injectors supplied by the trade these days, one really must question what is being peddled by the ME suppliers and where it has come from.

I appreciate that Neil must defend his advertisers in his magazine, but this is no excuse for shoddy goods passed off as in the way they are described in those ME supplier's literature etc.

Cheers,

Julian

Edited By julian atkins on 02/03/2017 23:50:03

3 March 2017 at 00:00 #286818David Taylor

Participant@davidtaylor63402I find them frustrating too. The problem is there is so much that can be wrong – the pipe work, water valves, clack valves, cones – positioning or gunked up, water temperature, pressure range, the list just goes on. It's a wonder the damned things ever work. During the summer months down under its even worse and sometimes if you don't put ice in your tender you're out of luck. Then of course they all have different threads for the connections! I have a pair from somewhere and even the bloke in the club who made a living building and fixing locos didn't have a tap or die they'd match.

My club really frowns upon axle pumps so we all run two injectors. I get the feeling on many locos only one of them works reliably and gets used all the time with the other one only used in emergencies when the 'good' one decides to play up. Way too much of my driving time is spent watching the injector overflow and fiddling with water and steam valves trying to keep water in the boiler.

I can't say I'd blame anyone for fitting either an axle pump or an electric pump as a way of getting water in their boiler, especially with a bypass so you could have a chance at setting it to keep a decent water level most of the time.

It might be a good project to have a testing setup of some sort with a boiler, water tank, and just enough pipe work to test the rotten things.

It seems unless you can make them yourself you'll probably fall foul of them at some point.

3 March 2017 at 01:37 #286820 Simon CollierParticipant@simoncollier74340

Simon CollierParticipant@simoncollier74340This is a very interesting thread. I was going to ask Julian if he could recommend any injectors but he has spared me the trouble by mentioning them above. A good injector is as reliable a a light switch. I drive my Simplex on our very busy monthly running days for 3 hours straight. I have a tank on the riding truck for cool water supply. I leave the water on constantly and use the single injector which snaps on every time. I have lightly pickled it a couple of times in several years (soft water here). In contrast, a loco I finished for someone and fitted 2 injectors and an axle pump has given constant trouble. Despite attention to water valves, clacks and pipework on a couple of occasions, the owner relies entirely on the axle pump. I'll have yet another look at it sometime but it is a big disappointment. Thinner walled 3/16 pipe might help as I suspect the easily available 20 G stuff has too small a bore.

3 March 2017 at 08:49 #286837 Neil WyattModerator@neilwyattPosted by julian atkins on 02/03/2017 23:48:04:

Neil WyattModerator@neilwyattPosted by julian atkins on 02/03/2017 23:48:04:I appreciate that Neil must defend his advertisers in his magazine, but this is no excuse for shoddy goods passed off as in the way they are described in those ME supplier's literature etc.

No excuses, they need to be ready to put things right if they sell faulty gear, just like anyone else should.

I just hadn't heard of, and couldn't find, any reference to Chinese made injectors, but if Ron has been told that some of the one he has had are imported, I'm happy to accept that.

We do benefit from many specialist suppliers who have an understanding of the hobby. Clearly while others have had no problems with injectors from multiple sources, Ron has had a string of bad ones. If he and other people who get such items don't feed back to the suppliers nothing will be done.

Ironically, injectors are the sort of precision product where CNC mass production should offer reliability and consistency. I suspect the problem is that the volumes out of China will never be large enough to justify the investment in time to get them right. Alternatively, perhaps a UK supplier with in-house CNC might wish to rise to the challenge.

Neil

3 March 2017 at 08:54 #286838Stewart Hart

Participant@stewarthart90345Injectors always seem to generate a lot of discussion:- probably because they are a bit of an enigma, I've observed that some people seem to have no problems with them whilst others struggle.

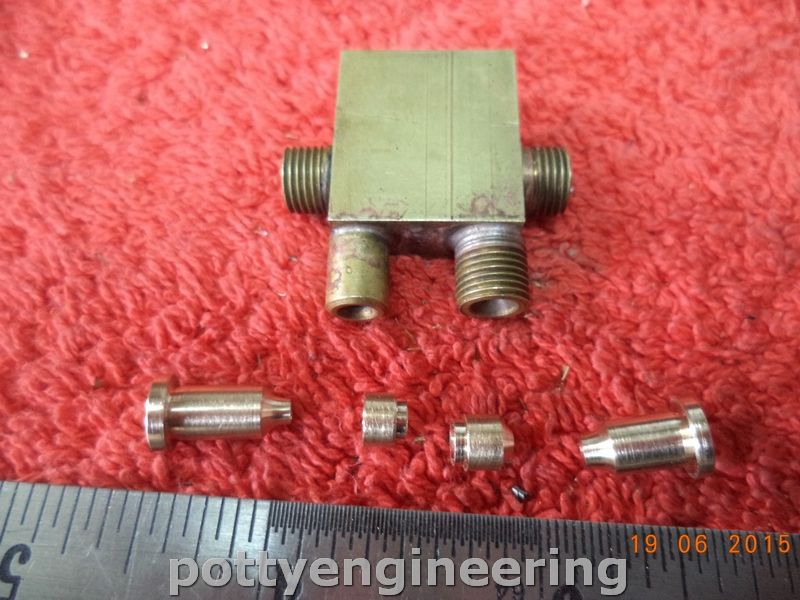

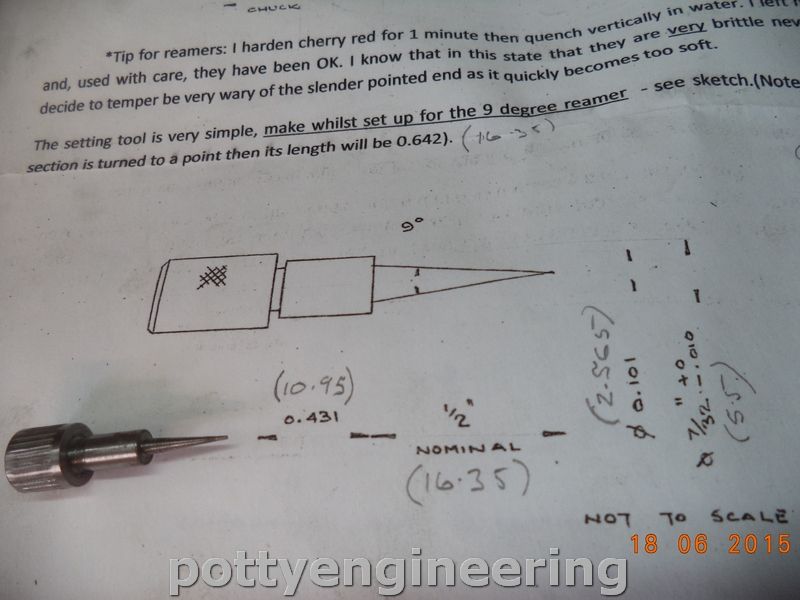

I fitted a commercial injector to my Simplex when I completed it, and it worked fine. But I fancied a go at making my own so read up on it, and to be honest I was far from happy as to how the great and good in Model Engineering described the process, they seemed to make it sound all to easy, but from my own research and long study of drawings I didn't feel that confident to start. Then a fellow club member offered to give me some tuition on the subject, this prompted me to have a go:- I made a batch of five as I reasoned that I would get at least one of the five running, In the end I got all five working, one is fitted to my Simplex and works flawlessly all I do is clean it in white vinegar once a year I've kept one back for spare the rest I've given to fellow club members and are in regular use.

Her are a few pictures of the tooling its not the only way to make them but it worked for me.

Cheers

Stew

3 March 2017 at 12:04 #286868Ron Hancock

Participant@ronhancock63652Posted by Simon Collier 1 on 03/03/2017 01:37:12:This is a very interesting thread. I was going to ask Julian if he could recommend any injectors but he has spared me the trouble by mentioning them above. A good injector is as reliable a a light switch. I drive my Simplex on our very busy monthly running days for 3 hours straight. I have a tank on the riding truck for cool water supply. I leave the water on constantly and use the single injector which snaps on every time. I have lightly pickled it a couple of times in several years (soft water here). In contrast, a loco I finished for someone and fitted 2 injectors and an axle pump has given constant trouble. Despite attention to water valves, clacks and pipework on a couple of occasions, the owner relies entirely on the axle pump. I'll have yet another look at it sometime but it is a big disappointment. Thinner walled 3/16 pipe might help as I suspect the easily available 20 G stuff has too small a bore.

Good luck with it glad your own works ok the frustration is so imense when your new and only think that it has to be your own work. i am so lucky to have Julian helpng me a man i have never met but spoke on here and has been amazing. without his help and encouragment i would have sold it by now. to see this injector he made work so well is like winning the lottery.

Ron

3 March 2017 at 12:08 #286870SillyOldDuffer

Moderator@sillyolddufferCoincidence is a strange thing. I bought a box of old magazines a few weeks ago and today's breakfast read was ME 16th June 1967.

The full text of the correction is: the steam cone was shown as entering into the first part of the combining cone by 0.090 in. This should have been 0.040 in.

In another recent thread I asked advice on how to turn a handle for a rolling pin. I have yet to complete that job successfully. Looking at the cones in Martin Evan's injector drawing is slightly depressing, I see I still have an awful lot to learn.

Dave

3 March 2017 at 12:13 #286873Ron Hancock

Participant@ronhancock63652Posted by Stewart Hart on 03/03/2017 08:54:47:Injectors always seem to generate a lot of discussion:- probably because they are a bit of an enigma, I've observed that some people seem to have no problems with them whilst others struggle.

I fitted a commercial injector to my Simplex when I completed it, and it worked fine. But I fancied a go at making my own so read up on it, and to be honest I was far from happy as to how the great and good in Model Engineering described the process, they seemed to make it sound all to easy, but from my own research and long study of drawings I didn't feel that confident to start. Then a fellow club member offered to give me some tuition on the subject, this prompted me to have a go:- I made a batch of five as I reasoned that I would get at least one of the five running, In the end I got all five working, one is fitted to my Simplex and works flawlessly all I do is clean it in white vinegar once a year I've kept one back for spare the rest I've given to fellow club members and are in regular use.

Her are a few pictures of the tooling its not the only way to make them but it worked for me.

Cheers

Stew

Hi stew very impressed any one who van make one of these like you and Julian my hat comes of true model engineers. just wish more where made that worked from suppliers. i have seen so many that don't work at clubs i have been to with guys building Loco's over 30 years still having problem and yes not always the injector mine has been clacks that Julian had to machine. i took some back to polly they checked none where seating and blow me the replacments didnt either till Julian worked on them.

I find it so intresting how you make them and your tooling wish i was that clever or young enough to tackle making them.

Ron

3 March 2017 at 12:15 #286875Ron Hancock

Participant@ronhancock63652Posted by Neil Wyatt on 03/03/2017 08:49:48:Posted by julian atkins on 02/03/2017 23:48:04:I appreciate that Neil must defend his advertisers in his magazine, but this is no excuse for shoddy goods passed off as in the way they are described in those ME supplier's literature etc.

No excuses, they need to be ready to put things right if they sell faulty gear, just like anyone else should.

I just hadn't heard of, and couldn't find, any reference to Chinese made injectors, but if Ron has been told that some of the one he has had are imported, I'm happy to accept that.

We do benefit from many specialist suppliers who have an understanding of the hobby. Clearly while others have had no problems with injectors from multiple sources, Ron has had a string of bad ones. If he and other people who get such items don't feed back to the suppliers nothing will be done.

Ironically, injectors are the sort of precision product where CNC mass production should offer reliability and consistency. I suspect the problem is that the volumes out of China will never be large enough to justify the investment in time to get them right. Alternatively, perhaps a UK supplier with in-house CNC might wish to rise to the challenge.

Neil

Hope so would be nice if they do

Ron

3 March 2017 at 12:24 #286878Ron Hancock

Participant@ronhancock63652Posted by David Taylor on 03/03/2017 00:00:38:I find them frustrating too. The problem is there is so much that can be wrong – the pipe work, water valves, clack valves, cones – positioning or gunked up, water temperature, pressure range, the list just goes on. It's a wonder the damned things ever work. During the summer months down under its even worse and sometimes if you don't put ice in your tender you're out of luck. Then of course they all have different threads for the connections! I have a pair from somewhere and even the bloke in the club who made a living building and fixing locos didn't have a tap or die they'd match.

My club really frowns upon axle pumps so we all run two injectors. I get the feeling on many locos only one of them works reliably and gets used all the time with the other one only used in emergencies when the 'good' one decides to play up. Way too much of my driving time is spent watching the injector overflow and fiddling with water and steam valves trying to keep water in the boiler.

I can't say I'd blame anyone for fitting either an axle pump or an electric pump as a way of getting water in their boiler, especially with a bypass so you could have a chance at setting it to keep a decent water level most of the time.

It might be a good project to have a testing setup of some sort with a boiler, water tank, and just enough pipe work to test the rotten things.

It seems unless you can make them yourself you'll probably fall foul of them at some point.

Hi David where down under do you come from and yes never thought about how they perform down under in the heat their. Whilst visiting my Daughter in Melbourne we went to Cambel toen railway he has a lovely set up 2 12 mile track round his garden 3 steam two deisel and runs every weekend giving rides. He was after some injectors for his 7 14 he is not on the internet so not sure how he got on.

I think in the future clubs need to have built a test bed to test injectors it would really help as all my bought ones need work but lucky Julian is doing mine for me an amazing guy.

Enjoy the cooler weather coming soon for you whilst we have our summer but yours is still like our summer in the winter great to hear from you.

Ron

3 March 2017 at 12:32 #286880Ron Hancock

Participant@ronhancock63652Posted by SillyOldDuffer on 03/03/2017 12:08:14:Coincidence is a strange thing. I bought a box of old magazines a few weeks ago and today's breakfast read was ME 16th June 1967.

The full text of the correction is: the steam cone was shown as entering into the first part of the combining cone by 0.090 in. This should have been 0.040 in.

In another recent thread I asked advice on how to turn a handle for a rolling pin. I have yet to complete that job successfully. Looking at the cones in Martin Evan's injector drawing is slightly depressing, I see I still have an awful lot to learn.

Dave

Hi Dave some one suggested a book to me about injectors called miniture injectors inside and out by d.a.g. brown its very in depth but maths was never my strong point went over my head but it seems to cover everything. i think i will just stay with the ones Julian is doing for me to old to take in plus having Alzhimers does not help at least trying to sort my loco out keeps the brain working a little.

Ron

3 March 2017 at 23:26 #287014julian atkins

Participant@julianatkins58923The only crucial dimension when the steam cone enters the first part of the combining cone is the annular gap.

Both Eric Rowbottam in ME 1976, and in DAG (Derek) Brown's books and articles provide a fool proof method of assessing/gauging same. Eric's method has been in print for 40 plus years so there is no secret.

If you dont get the annular gap correct on the steam cone then even if everything else is spot on to drawings for the other bits, then the injector is unlikely to work.

Gordon Chiverton used a smaller steam cone nozzle than in the DAG Brown articles and his excellent book, and used a larger combining cone 'throat' size. This gives Gordon's injectors their strong lifting characteristics . Gordon's annular gap was quite a bit more than Derek's standards for any size of injector.

Martin Evans never made an injector himself. He copied the C.M. Keiller injector proportions published in ME in 1962, but had very limited experience of driving and firing miniature locos, and had no personal knowledge of how to make injectors other than which others such as Keiller had written in ME. He was completely ignorant of the details of the highly successful designs of Ted Linden. So I would tread a bit carefully with anything written by Martin Evans about injectors!

If you want my own rather long and boring comments on injectors have a look at this

Cheers,

Julian

4 March 2017 at 08:39 #287029Stewart Hart

Participant@stewarthart90345Posted by julian atkins on 03/03/2017 23:26:05:If you want my own rather long and boring comments on injectors have a look at this

Cheers,

Julian

Hi Julian

Thanks for this very interesting link:- just spent the last hour reading it, there was an awful lot to take in I understood a fair bit of it but will go back and read it again to try and take in the rest, some of the comments about the tooling, assembly methods etc rang true with me from my own experience when I made my own batch of injectors. One thing that did become apparent from the various successful injectors from a range of different makers discussed in the thread is that there are a lot of subtle interaction going on.

I was tutored by a friend ,Peter: who knows Dag Brown, the injectors are to Peters design but I suspect that they will lean heavily on Dags designs, the obvious difference being is the design of the body this is simply a Piece of 3/8" thick Brass Bar cut to size with the couplings soldered on. As well as the drawing Peter supplied me a step by step procedure on how to machine and assemble the the injectors. I did deviate from Peters instructions slightly to suite my own equipment, and suggest to Peter that instead of having a interference fit with the combining cones to fit them with loctite, but he advised against this as he had tried it and found that the heat softened the adhesive and the cones moved and the injectors stopped working, but being a bit of an experimenter by nature I obtain some high temperature loctite and so far after 18 months of use its not let me down.

I was lucky to have Peter to tutor me, any one contemplating having a go at making their own injectors, I would advice them to seek out an experienced tutor, injectors are not like the run of the mill item, you have to adopt a different approach but once you have grasped the principles they should be within the capability of any experienced model engineer:-

lets face it if you go down the track with a loco fitted with your own injector you certainly get some bragging rights.

Thanks again for sharing your experiences

Stew

Edited By Stewart Hart on 04/03/2017 08:41:16

4 March 2017 at 09:56 #287045Ron Hancock

Participant@ronhancock63652Posted by julian atkins on 03/03/2017 23:26:05:The only crucial dimension when the steam cone enters the first part of the combining cone is the annular gap.

Both Eric Rowbottam in ME 1976, and in DAG (Derek) Brown's books and articles provide a fool proof method of assessing/gauging same. Eric's method has been in print for 40 plus years so there is no secret.

If you don't get the annular gap correct on the steam cone then even if everything else is spot on to drawings for the other bits, then the injector is unlikely to work.

Gordon Chiverton used a smaller steam cone nozzle than in the DAG Brown articles and his excellent book, and used a larger combining cone 'throat' size. This gives Gordon's injectors their strong lifting characteristics . Gordon's annular gap was quite a bit more than Derek's standards for any size of injector.

Martin Evans never made an injector himself. He copied the C.M. Keiller injector proportions published in ME in 1962, but had very limited experience of driving and firing miniature locos, and had no personal knowledge of how to make injectors other than which others such as Keiller had written in ME. He was completely ignorant of the details of the highly successful designs of Ted Linden. So I would tread a bit carefully with anything written by Martin Evans about injectors!

If you want my own rather long and boring comments on injectors have a look at this

Cheers,

Julian

Hi Julian well you certainly know injectors i thought it was great to read but have to admit it went over my head.

i learned a lot from reading but know i could never ever be able to work to such close tolerances.

i think so many will be very pleased to learn more about them you really do make it interesting and help to solve the mysteries of them.

Did my other injectors arrive in post so interested to see if you found any thing wrong with them.

i know one will be past repair and my fault but i learn what is wrong after you look at them and find fascinating.

look forward to hearing outcome.

a very grateful Ron

4 March 2017 at 18:58 #287146SillyOldDuffer

Moderator@sillyolddufferPosted by julian atkins on 03/03/2017 23:26:05:…

If you want my own rather long and boring comments on injectors have a look at this

Cheers,

Julian

You're too modest Julian, that's a very interesting read. Thanks for providing it.

Dave

4 March 2017 at 21:46 #287173julian atkins

Participant@julianatkins58923Hi Stew and Dave,

Glad to hear my ramblings were of interest to a few.

Anyway, Ron sent me 2 injectors in the post. One is an example from Reeves that I've not seen before and is a bit odd, and anyway is unfortunately a 'bin job' due to an unfortunate fatal accident.

The other is of a type I have now 4 examples of sent to me by exasperated loco owners who have purchased same all in the last few years from 2 particular well known ME suppliers.

In the above 4 cases the original steam cones are a rattling fit in the bodies and the delivery cones arent much better.

Ron's example has cone sizes of say No.56/46 thou (steam cone throat), No.66/33 thou (combining cone throat), and No.71/26 thou (delivery cone throat).

This is way way off the radar of what will work! The others are pretty much similar.

To add to the complications the loose steam cone nozzle is 83 thou OD, and wont even fit into the converging tapered first part of the combining cone being far too big, and more suitable for a much larger injector. It is also too short by 25 thou.

The combining cone proportions are also not ideal in length – the 2 halves being shorter than standard.

Now if anyone can make out a case for a 56/66/71 cone sizing to work I would be very pleased to hear from them!

Usual sizes for this type would be 60/65or 64/70.

Someone is currently making and selling to some of the ME suppliers the most lousy badly made bits of brass that will never work, and giving miniature loco injectors a bad name in the process.

I should add I have no commercial interest whatsoever in this matter. I make my own injectors and a few for close friends. I detest repetitive work, and the idea of making these gadgets commercially would bore me to tears and drive me up the wall.

Cheers,

Julian

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Locomotives › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Chimney turning

Started by:

dave22 in: Beginners questions

- 2

- 4

-

3 September 2025 at 22:39

noel shelley

-

Arc’s 25mm indexable end mills…

Started by:

gerry madden in: General Questions

- 3

- 3

-

3 September 2025 at 22:37

IanT

-

Swing over bed limitation for flywheels

Started by:

Steve Huckins

in: General Questions

Steve Huckins

in: General Questions

- 15

- 22

-

3 September 2025 at 21:25

Engine Builder

-

An Unexpected Message

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 6

- 8

-

3 September 2025 at 21:12

Michael Gilligan

Michael Gilligan

-

Play on warco mini lathe saddle

Started by:

Michael Callaghan in: Manual machine tools

- 4

- 9

-

3 September 2025 at 17:50

Howard Lewis

-

Safe and secure way to suspend a 5″G Tender

Started by:

Greensands in: Locomotives

- 6

- 7

-

3 September 2025 at 14:51

Nealeb

-

Denford Orac refit

Started by:

Richard Evans 2 in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 5

- 19

-

3 September 2025 at 14:30

Stuart Smith 5

-

design and use of cutting tools

Started by:

john mostyn in: Books

- 8

- 9

-

3 September 2025 at 14:25

cogdobbler

cogdobbler

-

Alternatives for a DRO display change

Started by:

John Hinkley

in: General Questions

John Hinkley

in: General Questions

- 8

- 24

-

3 September 2025 at 13:53

SillyOldDuffer

-

What Did You Do Today 2025

1

2

…

9

10

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 38

- 244

-

3 September 2025 at 13:05

Vic

Vic

-

Vallder CNC

Started by:

Michael Gilligan

in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

Michael Gilligan

in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 1

- 1

-

3 September 2025 at 08:38

Michael Gilligan

Michael Gilligan

-

Big Vise, go big or go home

Started by:

conrod in: Workshop Tools and Tooling

- 6

- 6

-

2 September 2025 at 20:00

old mart

-

Parting off on a mini lathe

Started by:

Andy Brocklehurst in: Beginners questions

- 18

- 25

-

2 September 2025 at 19:43

old mart

-

St Albans Big Show 27 & 28 Sept 25

Started by:

Bazyle

in: Exhibitions, Shows and Club Events

Bazyle

in: Exhibitions, Shows and Club Events

- 2

- 3

-

2 September 2025 at 16:25

Bazyle

Bazyle

-

Exeter & District Model Engineers Show – 7 Sept

Started by:

Bazyle

in: Exhibitions, Shows and Club Events

Bazyle

in: Exhibitions, Shows and Club Events

- 1

- 1

-

2 September 2025 at 16:22

Bazyle

Bazyle

-

Task Light

Started by:

Vic

in: Work In Progress and completed items

Vic

in: Work In Progress and completed items

- 2

- 3

-

2 September 2025 at 15:15

Vic

Vic

-

alchin transfers

Started by:

joseph tatler in: Traction engines

- 4

- 4

-

2 September 2025 at 13:19

Clive Brown 1

-

Watercress Queen

Started by:

Diogenes in: Locomotives

- 3

- 3

-

2 September 2025 at 12:38

JA

JA

-

NU tool milling machine

Started by:

joseph tatler in: Manual machine tools

- 8

- 13

-

2 September 2025 at 10:31

joseph tatler

-

Newbie

Started by:

seanieboy in: Introduce Yourself – New members start here!

- 4

- 4

-

2 September 2025 at 10:25

Howard Lewis

-

Feed Water

1

2

Started by:

Richard Simpson

in: General Questions

Richard Simpson

in: General Questions

- 16

- 31

-

2 September 2025 at 09:44

noel shelley

-

Looking for a quality pencil sharpener

Started by:

Greensands in: The Tea Room

- 11

- 13

-

2 September 2025 at 08:56

Richard Simpson

Richard Simpson

-

Softening epoxy

1

2

Started by:

John Haine in: General Questions

- 23

- 42

-

2 September 2025 at 04:23

John Haine

-

Thread form of medical ‘screws’.

Started by:

JimmieS in: The Tea Room

- 7

- 11

-

1 September 2025 at 20:45

JimmieS

-

Knowledge

Started by:

seanieboy in: Introduce Yourself – New members start here!

- 5

- 5

-

1 September 2025 at 19:39

Roderick Jenkins

Roderick Jenkins

-

Chimney turning

-

Latest Issue

Newsletter Sign-up

Latest Replies

- Chimney turning

- Arc’s 25mm indexable end mills…

- Swing over bed limitation for flywheels

- An Unexpected Message

- Play on warco mini lathe saddle

- Safe and secure way to suspend a 5″G Tender

- Denford Orac refit

- design and use of cutting tools

- Alternatives for a DRO display change

- What Did You Do Today 2025