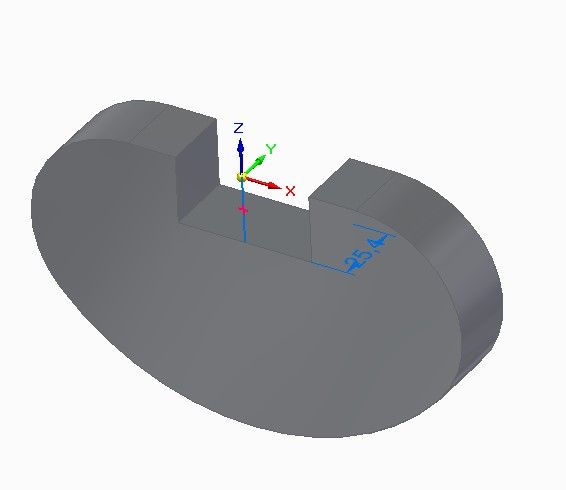

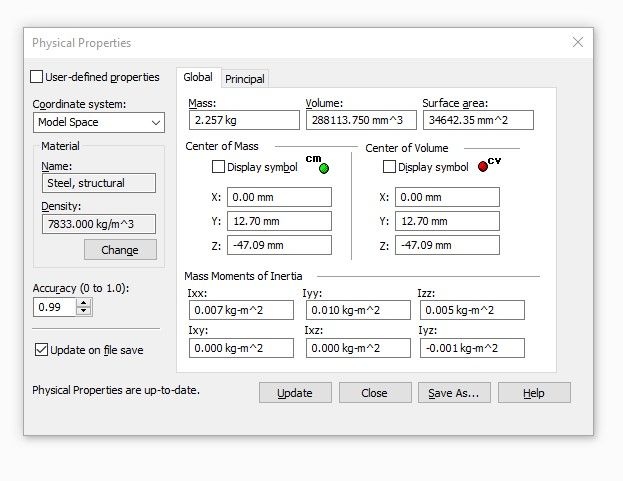

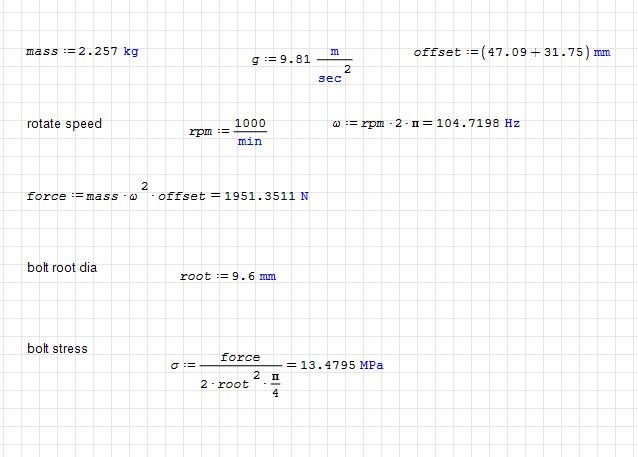

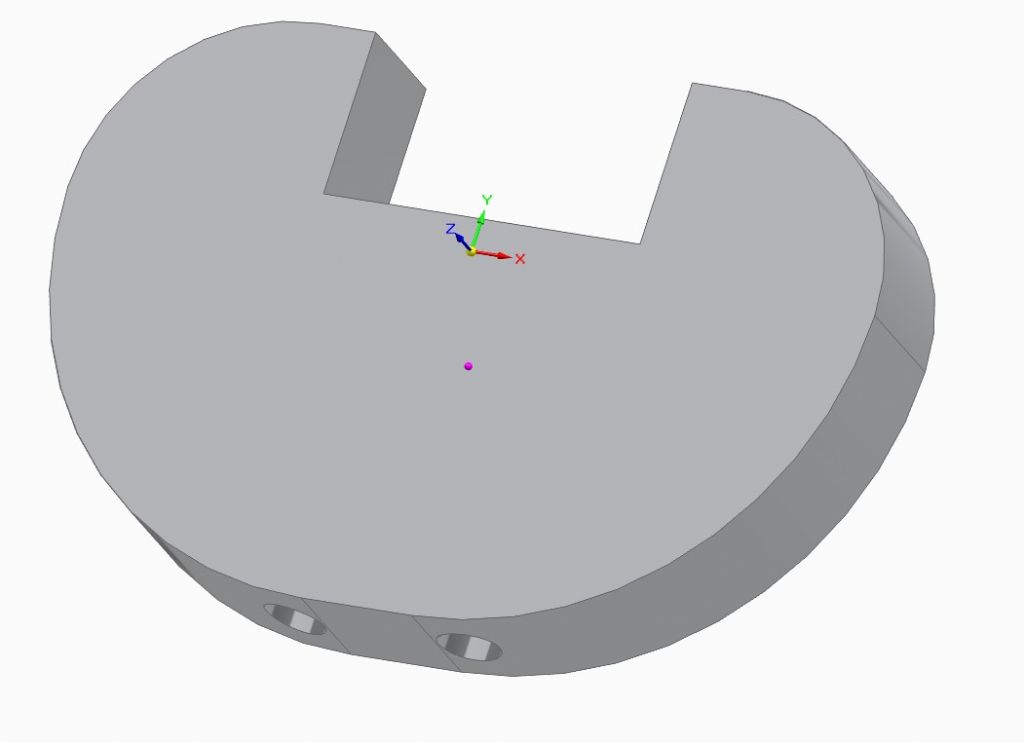

Duncan's suggestion of establishing the mass of the counter-balance was a good one. If the mass and rotational speed are known, it's easy to calculate the centripetal force on the bolts:

F = mv²/r

m is mass,

v is velocity

r is radius, distance from the axle's axis

An ordinary nasty M20 bolt will take about 9000kg force. 8.8 high-tensile bolts about twice that, and 12.9 bolts three times.

Not done the sums because the weight has to be CAD extracted but I suspect a 5" scale-model traction engine doesn't put an enormous strain on the bolts compared with a full-size engine worked hard every day for years on end. Traction engines are low RPM.

High-tensile is probably specified on the full-size engine because the extra strength resists fatigue stress, especially if torqued properly. The strength of bolt needed to hold a static load is much lower than one subjected to alternating stresses.

Doing the sums would reveal if a pair of ordinary bolts capable of holding 18 tons are good enough, or 8.8 at 36 tons are needed, or even the 54 tons provided by 12.9 bolts.

The breaking strain of an ordinary bolt gives an idea of how much damage the counter-balance could do if the bolts failed. An 18 ton punch in the face would hurt!

Dave

Edited By SillyOldDuffer on 27/12/2022 12:30:36

duncan webster 1.