Armed with the dimensions, you could contact specialist gear suppliers like Davall, HPC or Reliance, to see what they have to offer. But have a chair close by when they quote the price, just in case.

If you are near to them, it may be worth taking one of the existing gears to them as a pattern.

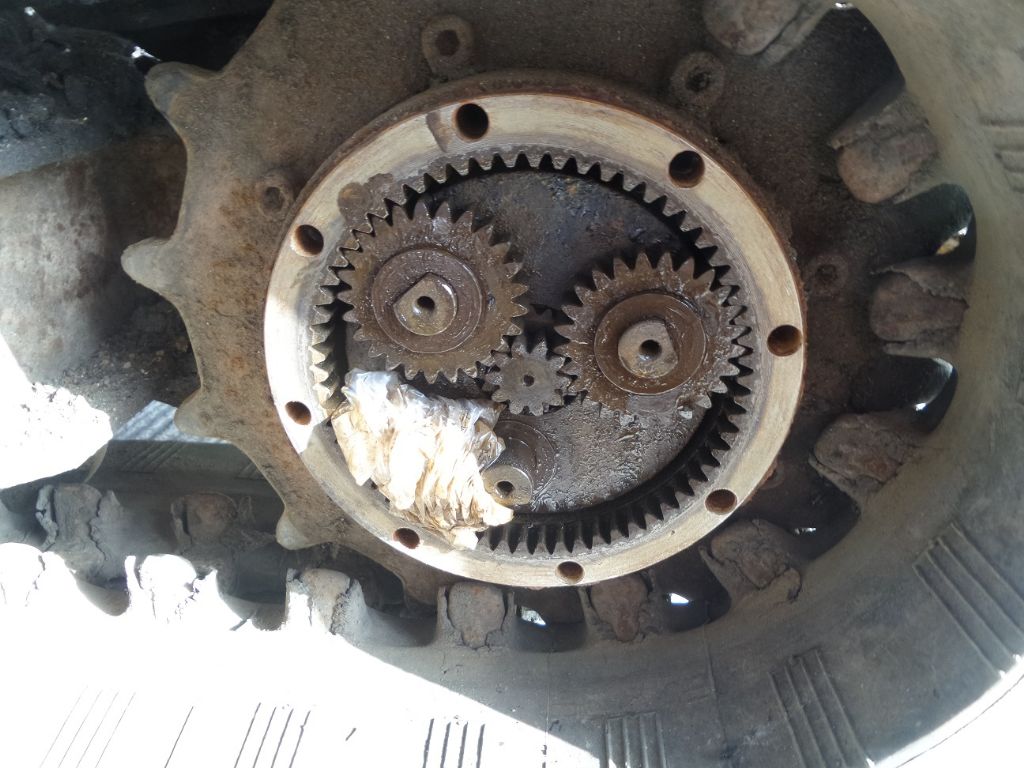

Since it seems likely o be metric, from your figures, it could be 2.25 Mod or maybe 2.5 Mod

My very old HPC catalogue ( C23 ) quotes a heavy duty steel gear XG2.5-25 as having 25 teeth and an OD of 67.5 mm, but it is 30 mm thick. Price, then was £30.28

The standard duty gear has the same dimensions, but is listed as PG2.5 – 25 and as 25 mm thick Priced at £22.72

XG and PG are plain gears without a boss. YG and G have a boss, which you would not need.

No doubt these were ex VAT prices and need to be increased considerably.

They quote a 23T 2.5 Mod gear as having a 62.5 mm OD

They don'r seem to mention anything between 2 Mod and 2.5 Mod.

If any of the above were to be suitable, you would need to turn half of it away to 12mm thickness you quote

HTH

Howard

John Reese.