Hello all,

I have an EMCO MAximat V10, refurbished some 15 years ago from 'well used' and am in the process of doing it again – not really needed, but I decide to add an 'electronic lead-screw' system of my own design, which led to the need to modify, make boxes and housing, which led to the need to paint,which…So , I managed to find as set of new gibs, carriage/compound leadscrews and nuts, main leadscrew and halfnuts, etc, etc…So now its a full refurbish!

Back to the the main topic..

( Note: Since the character count per post is so limited, this will be broken into a number of posts – I guess…)

Since my career was in the upper end of the electronics world ( flight control and weapons systems computers for jet fighters, helicopters, Drones ( big ones), etc) I thought I would try and design such an ELS myself…And since My good wife was an integral part of that career – was head of a major SW dept, accredited by BAE to do safety critical SW on BAE jets…What the heck – between us we should be able to do it…

I will try to post over the next weeks as the project progresses to do a sort of 'build-log', as we go.

The actual machine stripping is taking place in the background.

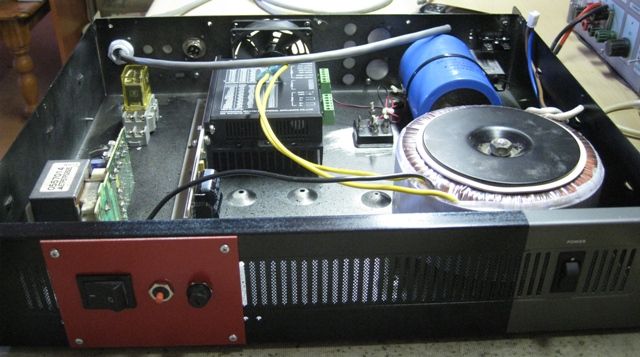

The intent is to create a microprocessor controlled box that can process electronics threading on any metric or imperial pitch, in an automated way, and provide simple, quiet Feed control for normal auto feed machining operations.

Basically there is a control panel that allows selection of a thread pitch/type, a way of defining the start and end points of the thread ( right or left hand thread as well) , left to right or right to left cuts, and then running the cut process automatically from start the end of thread, stopping the carriage feed and the spindle ( on a ticky, aided by the VFD on the spindle motor) , retract tool, press rewind and the tool goes to the start, put on cut, press start and the process repeats…

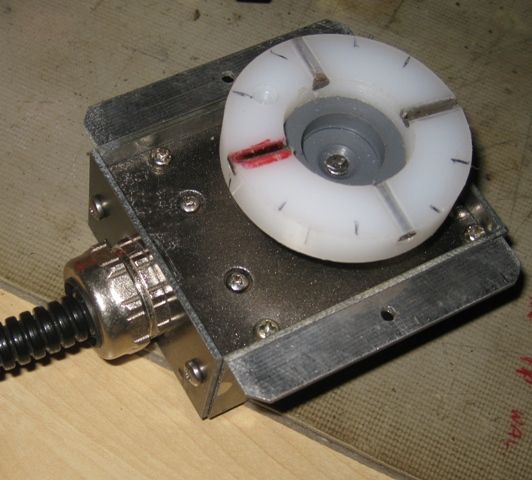

A largish stepper is fitted to the main leadscrew, which is disconnected from the Norton screwcutting box by removing the shearpin.

I have tried to keep it simple – it is too easy to add 'features' which in my opinion are a waste of time. Adding another stepper to the cross feed will allow machining of balls ( handles), tapers, etc, but for me the complexity is appalling, One does such work very rarely, and this gets in the way of the machine operation – with so many feature, buttons, operational methods, etc, it takes a half hour or more just to remember how to do something basic, and that defeats the whole purpose. If it takes longer to re-discover the operational process than it would take to cut a thread on a basic mechanical norton box lathe, then your have lost the plot… I would venture to say that ALL the ELS systems out there today are in that place – FAR to complex, trying to be a CNC substitute, but not really, so cannot do real CNC, and too painful to use for basic jobs.

Some PICS of the start of the project follow…

There is a Main and a Sub control panel – the Main is above the Headstock, with the Sub below the Swarf tray, left of the operator, at left pelvis height – main start stop buttons, etc…

Upper image is Sub panel, lower is Main, on the Bench in the Lab for SW testing.

CLoser view of Main Panel ( forgive the flash-back..) Managing setup selections.

And the Sub Control panel, managing actual Machining.

Next Post FOllows…..

Edited By Joseph Noci 1 on 12/03/2017 20:18:18

Joseph Noci 1.