I've got to the stage of mounting all the electronic bits in an enclosure. Typically, in a bid to keep the costs down, I went for a cabinet one size smaller than I should have, so things are getting a trifle cramped. In the end, I mounted the Launchpad PCB vertically to gain a little breathing room:

The perforated box at the bottom of the picture is the power supply for the toolpost-mounted spindle. The space to the left of it is reserved for the wall wart power adapter for the LaunchPad/ELS boost board combo.

I've also finished all the plug and socket wiring which is temporarily balancing on the surface grinder as I've run out of bench space!

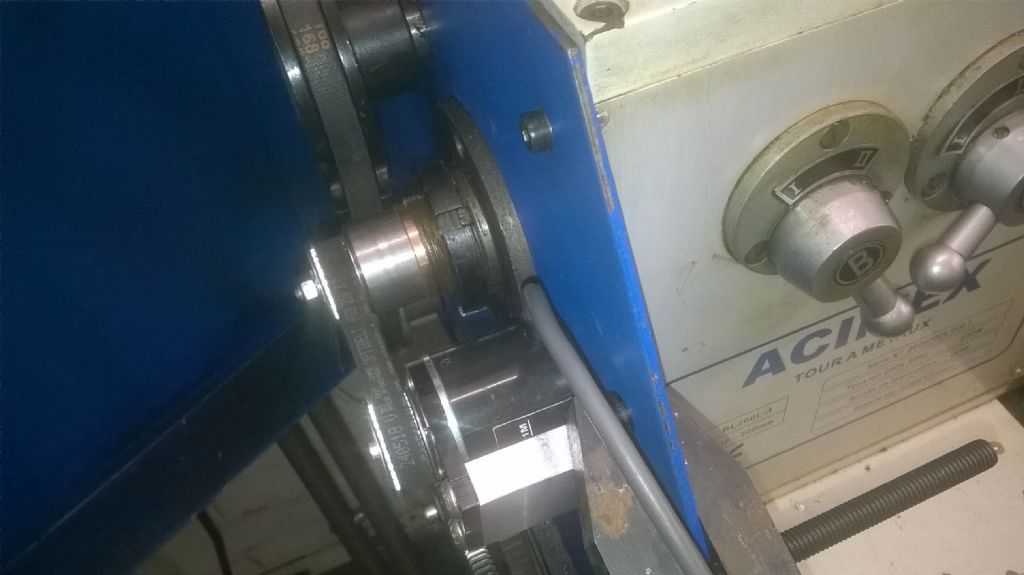

When the enclosure has been completed and wired together, I'll finish mounting the spindle encoder and leadscrew servo to the lathe. Despite all the effort I went to, in order to arrange the gearing for the spindle encoder to run off the headstock output shaft at spindle speed, I eventually went for an expanding mandrel in the spindle itself with a pullet mounted directly. It means that I can't get stock through the spindle, but I've never used that facility in all the years that I've had the lathe, and don't expect to need it in the future.

Here it is temporarily clamped in position with a toolmakers clamp. I did, at one stage, think that I'd never get this far! Hopefully a bit more progress in the coming days.

John

John Hinkley.

John Hinkley.