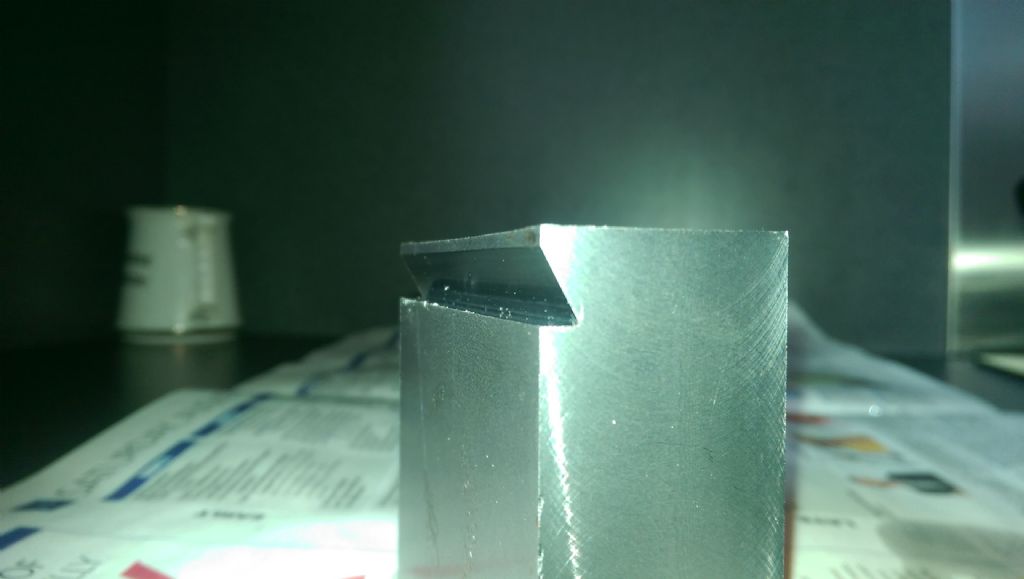

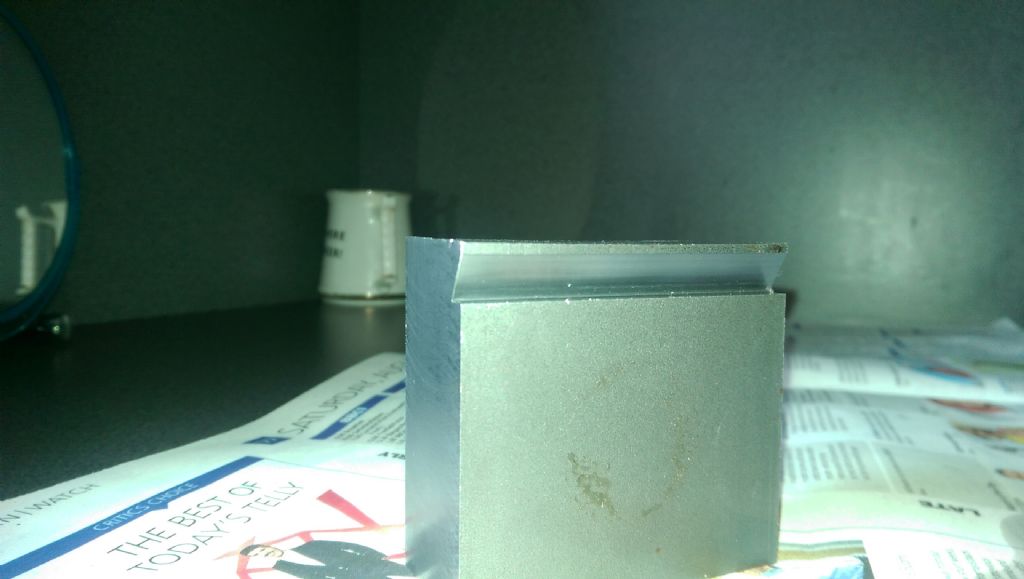

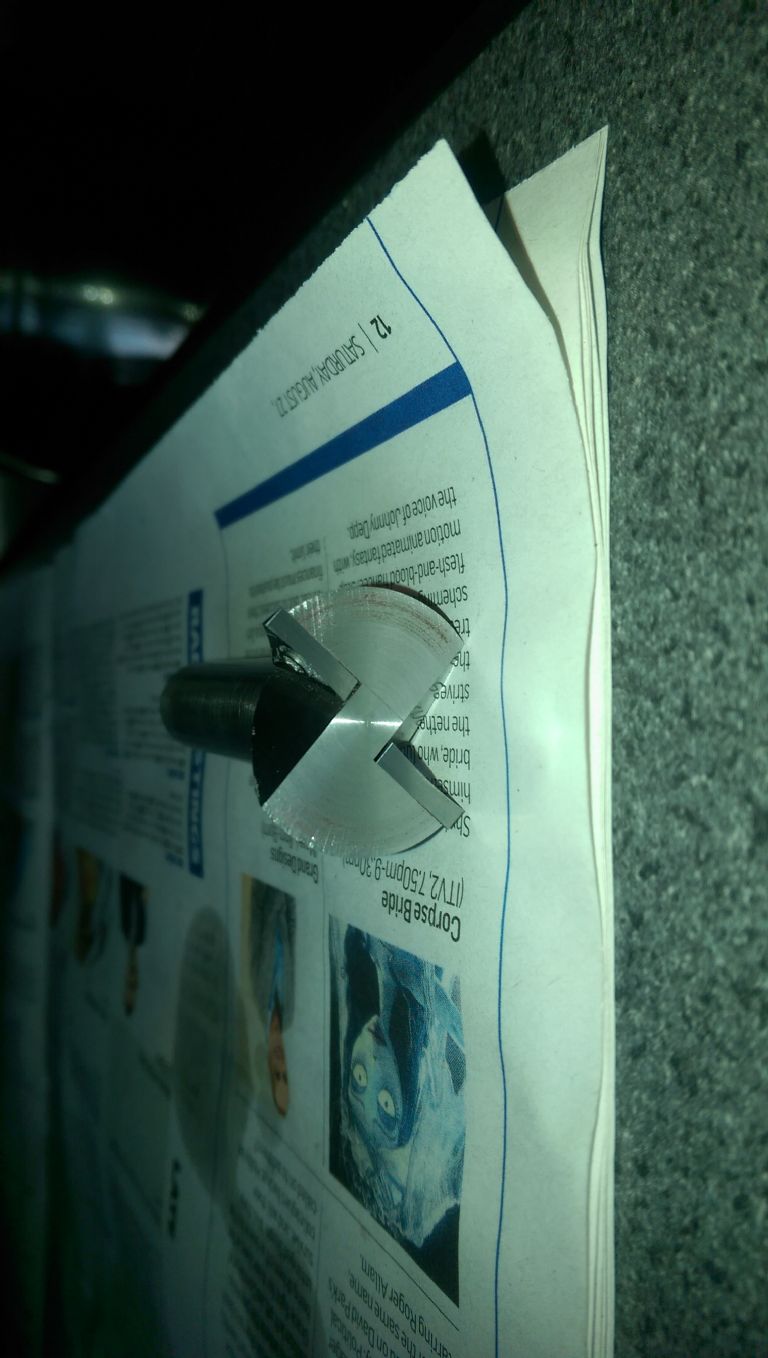

Hi Murray, In answer to your queries, No, the surface is cut with no burnishing. Because the inserts are 7° positive there is clearance for the trailing edge. After I cut the test piece I blued both the inserts [ actually a red Eddings marker ] on their edges and put the cutter back into the cut dovetail and rotated the spindle by hand shaving a minute amount off and the red remained on the back edges In fact you could actually see the clearance without the need for bluing. The inserts are mounted with their cutting edge exactly on the CL of the body.

With negative inserts then that would be a different scenario, and it would need to have the rake built into the mounting surface the same as negative toolholders I would never go back to a single insert as I value me spindle bearings too much and I hate the "hammer " thats the reason I dont like fly cutters although I will use them if I have to. The swarf came of as sort of needles terrible stuff to deal with.

Theory is all right at times, the Titanic should not have sunk "in theory " but it did. I prefer real world results. One bit of theory that I would agree with is the need for the inserts be be as close to perfect in relation to each other as you can get. That is as close as I can get them 0.005 and 0.007mm.

Bill , Its not unusual to hear a slitting saw give a "snick" every rev even the very best ones on the best arbors can do it. The inserts HAVE to be as close as possible 0.0 and 0.0 would be perfect but in the real world [at least in my world ] that will never happen .

.

Cheers.

Raymond Anderson.