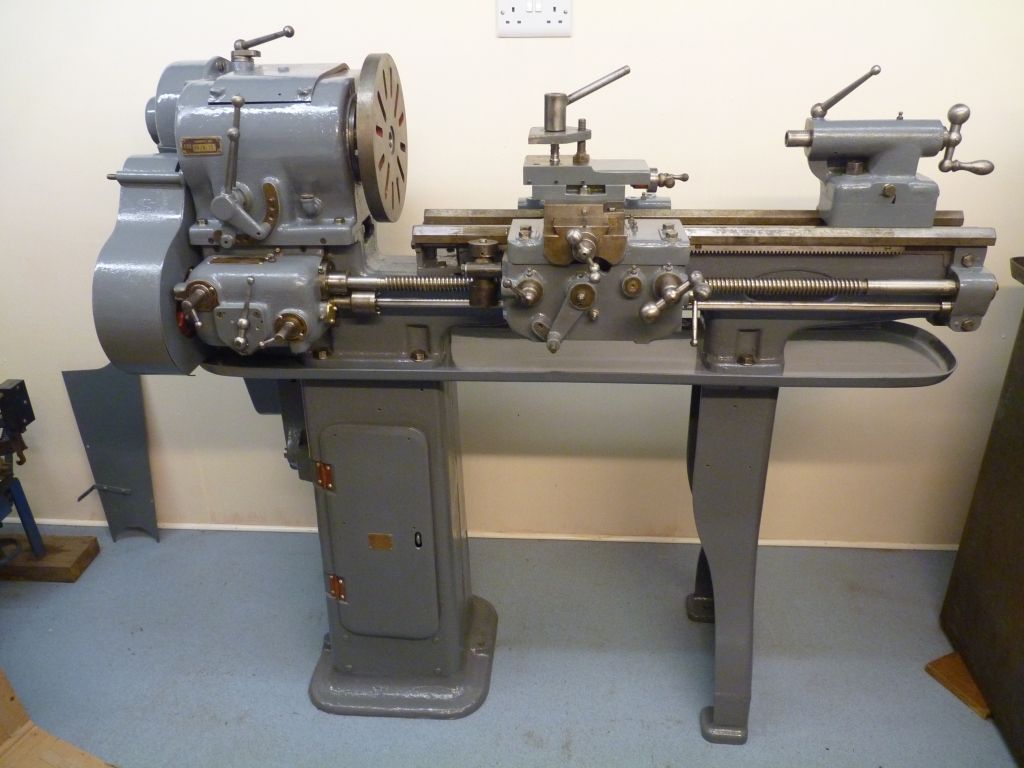

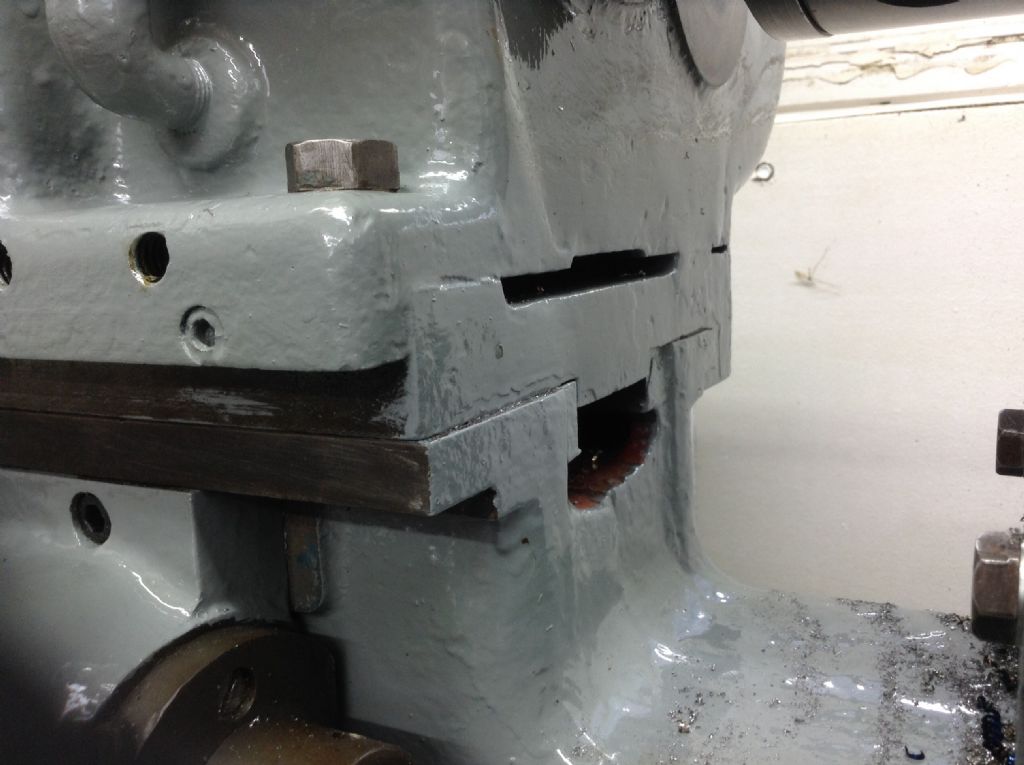

Many thanks for the pics John, very helpful. The only plaques that I have on it are Carriage Direction, A-B-C, Feeds In Out, and one on the top end belt guard showing belt direction. The only other witness holes from other plaques are on the front of the lower front guard, the left hand side of the headstock cupboard, top right above door on headstock cupboard, and the one on top of the lead screw gearbox. So if the number stamped in the bed isn't the serial number then I can't really date mine. The chuck speeds were faster than the legends on your Spindle Speeds plaque, so I've sourced a slightly smaller motor pulley, just as well because there was a bit of belt rub inside the guard so I guess it needed it anyway. I've attached a pic to show the 'height adjustment' plate under the headstock gearbox.

As an aside, regarding finding anything out about Denham, my next refurbishment is going to be a Walker Turner drill press, that has no serial number either. Through old manufacturer catalogues, I've managed to date it (1937-38), find out exactly what model it is, original purchase price, but also that when it was new it never came with an electric motor as standard, that was an extra!

Ivy.

Ivy.

Most of the plates are missing too but I do have the changewheel chart on the door but am missing a few wheels (25,30,100) and I really need the 30 and 100 wheels

Most of the plates are missing too but I do have the changewheel chart on the door but am missing a few wheels (25,30,100) and I really need the 30 and 100 wheels  .

.